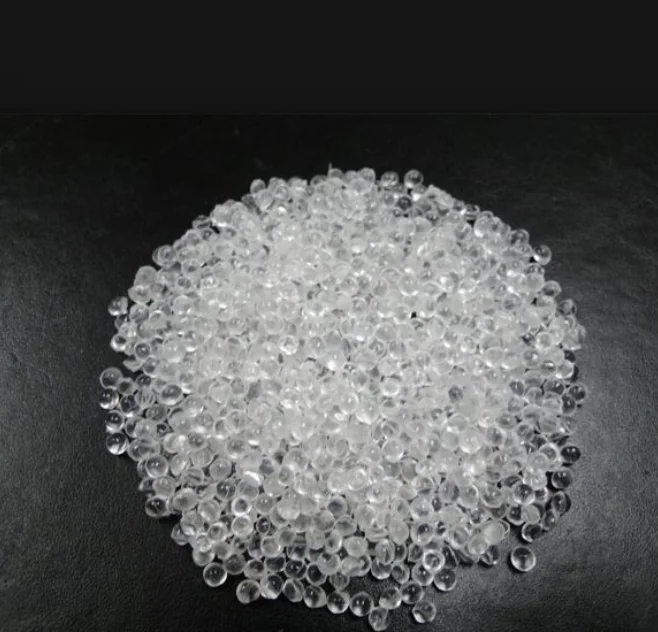

Японский ТПЭ JSR RB830 ТПР/ТПЭ подошва обуви модифицированный матовый противотуманный

- Категория: >>>

- Поставщик: Dongguan,Caixin,Plastic,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 36.74 $* | 38.37 $* |

| Aug-19-2025 | 35.96 $* | 37.59 $* |

| Jul-19-2025 | 30.63 $* | 32.1 $* |

| Jun-19-2025 | 35.8 $* | 37.28 $* |

| May-19-2025 | 30.79 $* | 32.17 $* |

| Apr-19-2025 | 34.25 $* | 36.30 $* |

| Mar-19-2025 | 34.33 $* | 36.30 $* |

| Feb-19-2025 | 34.55 $* | 36.19 $* |

| Jan-19-2025 | 33.17 $* | 35.56 $* |

Характеристики

Product Description

Specification

item | value |

Place of Origin | JSR RB830 |

Brand Name | JSR RB830 |

Model Number | JSR RB830 |

Matt Fog Agent | PVC |

Tpe Japanese | PVC |

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

POM PA TPU LCP COP PMMA PC PBT PC+ABS PC+PBT ABS EVATPO

FAQ

Second, material advantage.

UL 94 HB Certification.

Excellent mechanical properties.

Excellent coating properties for semi-aromatic polyamides (PAX), polyacrylamide (PARA) and polyamides (such as PA 12, PA6 and PA

6.6).

Easy to color (with natural color).

Resistant to skin care oils, sunscreen, olive oil and acetone.

TPE thermoplastic elastomer.

TPE combines the good processing properties of plastics and the advantages of elastomers for product developers and designers. TPE

material structure includes thermoplastic tail section and elastic middle section. As far as structure is concerned, TPE material

belongs to the class between plastic (thermoplastic) and rubber (elastomer), and gradually becomes a kind of material. This

material enables product upgrades and provides processors with an advantage over their competitors.In addition, TPE materials are

also in line with the current technical functions that only elastomers can meet, the use of TPE materials can not only obtain a

series of product advantages, but also bring economic benefits for manufacturers. Equivalent to thermoplastics, TPE materials are

plastic when heated and become elastomers after cooling. For elastomers, this reaction is due to chemical cross-linking. But for

TPE materials, this is the result of physical cross-linking, and all the changes caused by heat are reversible. When the material

cools, a new cross-linked structure is formed, and the elastic middle segment is embedded in the solid 3D network. This means that

the TPE material exhibits similar properties to the elastomer because it can be deformed repeatedly; the thermoplastic is

activated so that the TPE material can flow freely and is malleable.

A series of advantages that can be gained with TPE:

It is easy to process thermoplastics.

It can shorten the forming cycle of materials.

Reduce production energy consumption.

Thermal stability, providing larger forming area.

It can be processed with multiple materials, thus saving assembly costs.

Can join two kinds of materials (soft and hard joint).

The material is 100% recyclable.

A variety of coloring is possible, including in order to achieve more advanced design color effects.

TPE Kaibao K-Series MC/AD1 series is a material solution for basic medical approval (such as ISO 10993-5). This series is

characterized by excellent adhesive coating properties for polar thermoplastic materials such as PC, ABS and PC/ABS. These

compounds are produced only by specialized medical departments.

The TPE material of styrene is generally called TPS. TPS can be subdivided into SEBS, SBS, SEPS and SEPS-V. Kaibo Jiaobao mainly

produces SEBS (styrene block copolymer) materials. In this material, the styrene tail is connected to an elastic section

(ethylene-butene), and SEBS is used in hot melt bonding or as a soft component in dual-material injection molding.

The multiplicity of THERMOLAST ®compounds is as important as the results of our in-depth and professional development efforts in

specific customer groups and products. Our compounds have been tested and verified for special uses in the field of expertise.

The main features of our composite series include:

A good sense of touch.

Hardness ranges from 0 degrees Shore A to 60 degrees Shaw D.

High elasticity.

Anti-skid.

Excellent adhesion in the same thermoplastic (2C injection molding).

High transparency and multiple dyeing series.

The surface is suitable for writing and printing.

Best compression settings.

Excellent sealing characteristics.

Excellent deformation recovery.

High temperature resistance.

Good low temperature toughness.

Power insulation.

Excellent sound and vibration damping characteristics.

Resistance to hydrolysis.

Protection against amino acids, alkaline substances and oils.

Recyclable.

Sterilization.

Anti-weathering and anti-UV.

Kaibo Jiaobao widely used thermoplastic K material is developed to meet the needs of the market. This series of raw materials are

based on HSBC and are used in almost all industries. Kaibo Jiaobao has a stable supply of materials and has been tested for

special applications in multi-heavy industry.Kepper provides products such as special food-grade thermoplastic K-TPE and other

materials developed to meet the needs of the automotive industry. Kepper Jiaobao's materials can be processed in a variety of

processes: injection molding, extrusion or blow molding.

The application of TPE is multiple and extensive, which meets the special needs of industry. It can be used in the internal

control components of the vehicle, the external window layout and the sealing elements under the hood. TPE is also often used in

industrial products, such as tool handles and wire cladding. In terms of consumer goods, TPE is used in toys, sports equipment,

packaging and hygiene products, such as toothbrushes and razors. As for the application of medical devices, Kaibo Jiaobao has also

developed raw materials that can meet strict requirements. The application of TPE in this field, such as drop chamber, seals and

medical catheters, etc.

双语对照

文档翻译

网页翻译

UL 94 HB Certification.

Excellent mechanical properties.

Excellent coating properties for semi-aromatic polyamides (PAX), polyacrylamide (PARA) and polyamides (such as PA 12, PA6 and PA

6.6).

Easy to color (with natural color).

Resistant to skin care oils, sunscreen, olive oil and acetone.

TPE thermoplastic elastomer.

TPE combines the good processing properties of plastics and the advantages of elastomers for product developers and designers. TPE

material structure includes thermoplastic tail section and elastic middle section. As far as structure is concerned, TPE material

belongs to the class between plastic (thermoplastic) and rubber (elastomer), and gradually becomes a kind of material. This

material enables product upgrades and provides processors with an advantage over their competitors.In addition, TPE materials are

also in line with the current technical functions that only elastomers can meet, the use of TPE materials can not only obtain a

series of product advantages, but also bring economic benefits for manufacturers. Equivalent to thermoplastics, TPE materials are

plastic when heated and become elastomers after cooling. For elastomers, this reaction is due to chemical cross-linking. But for

TPE materials, this is the result of physical cross-linking, and all the changes caused by heat are reversible. When the material

cools, a new cross-linked structure is formed, and the elastic middle segment is embedded in the solid 3D network. This means that

the TPE material exhibits similar properties to the elastomer because it can be deformed repeatedly; the thermoplastic is

activated so that the TPE material can flow freely and is malleable.

A series of advantages that can be gained with TPE:

It is easy to process thermoplastics.

It can shorten the forming cycle of materials.

Reduce production energy consumption.

Thermal stability, providing larger forming area.

It can be processed with multiple materials, thus saving assembly costs.

Can join two kinds of materials (soft and hard joint).

The material is 100% recyclable.

A variety of coloring is possible, including in order to achieve more advanced design color effects.

TPE Kaibao K-Series MC/AD1 series is a material solution for basic medical approval (such as ISO 10993-5). This series is

characterized by excellent adhesive coating properties for polar thermoplastic materials such as PC, ABS and PC/ABS. These

compounds are produced only by specialized medical departments.

The TPE material of styrene is generally called TPS. TPS can be subdivided into SEBS, SBS, SEPS and SEPS-V. Kaibo Jiaobao mainly

produces SEBS (styrene block copolymer) materials. In this material, the styrene tail is connected to an elastic section

(ethylene-butene), and SEBS is used in hot melt bonding or as a soft component in dual-material injection molding.

The multiplicity of THERMOLAST ®compounds is as important as the results of our in-depth and professional development efforts in

specific customer groups and products. Our compounds have been tested and verified for special uses in the field of expertise.

The main features of our composite series include:

A good sense of touch.

Hardness ranges from 0 degrees Shore A to 60 degrees Shaw D.

High elasticity.

Anti-skid.

Excellent adhesion in the same thermoplastic (2C injection molding).

High transparency and multiple dyeing series.

The surface is suitable for writing and printing.

Best compression settings.

Excellent sealing characteristics.

Excellent deformation recovery.

High temperature resistance.

Good low temperature toughness.

Power insulation.

Excellent sound and vibration damping characteristics.

Resistance to hydrolysis.

Protection against amino acids, alkaline substances and oils.

Recyclable.

Sterilization.

Anti-weathering and anti-UV.

Kaibo Jiaobao widely used thermoplastic K material is developed to meet the needs of the market. This series of raw materials are

based on HSBC and are used in almost all industries. Kaibo Jiaobao has a stable supply of materials and has been tested for

special applications in multi-heavy industry.Kepper provides products such as special food-grade thermoplastic K-TPE and other

materials developed to meet the needs of the automotive industry. Kepper Jiaobao's materials can be processed in a variety of

processes: injection molding, extrusion or blow molding.

The application of TPE is multiple and extensive, which meets the special needs of industry. It can be used in the internal

control components of the vehicle, the external window layout and the sealing elements under the hood. TPE is also often used in

industrial products, such as tool handles and wire cladding. In terms of consumer goods, TPE is used in toys, sports equipment,

packaging and hygiene products, such as toothbrushes and razors. As for the application of medical devices, Kaibo Jiaobao has also

developed raw materials that can meet strict requirements. The application of TPE in this field, such as drop chamber, seals and

medical catheters, etc.

双语对照

文档翻译

网页翻译