Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 74922.80 $* | 78668.75 $* |

| Aug-15-2025 | 74293.16 $* | 78008.16 $* |

| Jul-15-2025 | 62330.54 $* | 65447.39 $* |

| Jun-15-2025 | 73034.77 $* | 76686.55 $* |

| May-15-2025 | 63590.3 $* | 66770.36 $* |

| Apr-15-2025 | 71774.16 $* | 75363.41 $* |

| Mar-15-2025 | 71145.7 $* | 74702.51 $* |

| Feb-15-2025 | 70515.45 $* | 74041.93 $* |

| Jan-15-2025 | 69886.4 $* | 73380.87 $* |

Характеристики

Product Overview

I. overview

The complete set of peanut butter production equipment has high mechanization, good reliability and fully closed production. It can process high-quality stable and smooth peanut butter, granular peanut butter and ordinary peanut butter. At the same time, it can also produce stable and ordinary sesame butter.

2 process flow

Raw materials → stone removal and impurity removal → baking → cooling → peeling → selection → rough grinding → blending → fine grinding → degassing → cooling → filling

3 main equipment

Elevator, stone removing and impurity removing machine, baking machine, rapid cooler, peeling machine, selection conveyor, automatic feeding device, roughing mill, blending

Conveying device, fine mill, cooling mixer, degasser, filling machine, electric control device

The complete set of peanut butter production equipment has high mechanization, good reliability and fully closed production. It can process high-quality stable and smooth peanut butter, granular peanut butter and ordinary peanut butter. At the same time, it can also produce stable and ordinary sesame butter.

2 process flow

Raw materials → stone removal and impurity removal → baking → cooling → peeling → selection → rough grinding → blending → fine grinding → degassing → cooling → filling

3 main equipment

Elevator, stone removing and impurity removing machine, baking machine, rapid cooler, peeling machine, selection conveyor, automatic feeding device, roughing mill, blending

Conveying device, fine mill, cooling mixer, degasser, filling machine, electric control device

PRODUCT SPECIFICATIONS

Model | Power (kw) | Capacity (kg/h) | Dimension (mm) |

130 | 11kw | 100-120 | 975*456*1054 |

180 | 18.5\\22kw | 180-220 | 981*476*1124 |

Product Feature

IV. technological process of sesame paste production line:

1 main process: raw materials - stone removal and impurity removal - baking - cooling - peeling - Selection - rough grinding - blending - fine grinding - cooling - degassing - filling.

2. Fine process: graded selection of sesame raw materials - sesame baking - cooling - peeling - germ removal - mixing - crushing and grinding - packaging

Processing equipment: Sesame baking machine - sesame peeling germ separator - mixer - sesame paste grinder - sesame paste filling and packaging machine

Output of Wuzhi sesame paste production line

1. Power of the production line: 40-80kw

2. Output: 3-5 tons / day

1 main process: raw materials - stone removal and impurity removal - baking - cooling - peeling - Selection - rough grinding - blending - fine grinding - cooling - degassing - filling.

2. Fine process: graded selection of sesame raw materials - sesame baking - cooling - peeling - germ removal - mixing - crushing and grinding - packaging

Processing equipment: Sesame baking machine - sesame peeling germ separator - mixer - sesame paste grinder - sesame paste filling and packaging machine

Output of Wuzhi sesame paste production line

1. Power of the production line: 40-80kw

2. Output: 3-5 tons / day

I. process flow and equipment composition of peanut butter production line

1 the process flow and main equipment of the production line include oven, peeling half granulator, picking belt, extractor, roughing mill, mixing tank, transfer pump, mixer, homogenizer, fine mill, vacuum tank, cooler, filling machine, etc. It is characterized by flow operation, high degree of mechanization, good performance and fully closed production. It is an equipment for producing stable peanut butter.

2 general equipment of peanut butter production line: oven, cooling belt, peeling machine, picking belt, roughing mill, ultra-fine mill, condenser, degassing tank and filling machine.

(1) Oven: bake peanuts.

(2) Cooling belt: the principle of extracting hot air by fan is used to cool the roasted peanuts.

(3) Peeling machine: peel the dried and roasted peanuts. During the peeling process, the peanuts are separated automatically to ensure the quality of the peeled peanuts.

(4) Picking belt: pick unqualified peanuts and some food residues.

(5) Roughing mill: the first grinding of peanuts.

(6) Superfine film: further grind the rough ground peanut to further improve the processing fineness.

(7) Condenser: cool the ground peanut butter.

(8) Degassing tank: degassing peanut butter before filling.

(9) Filling: filling and packaging.

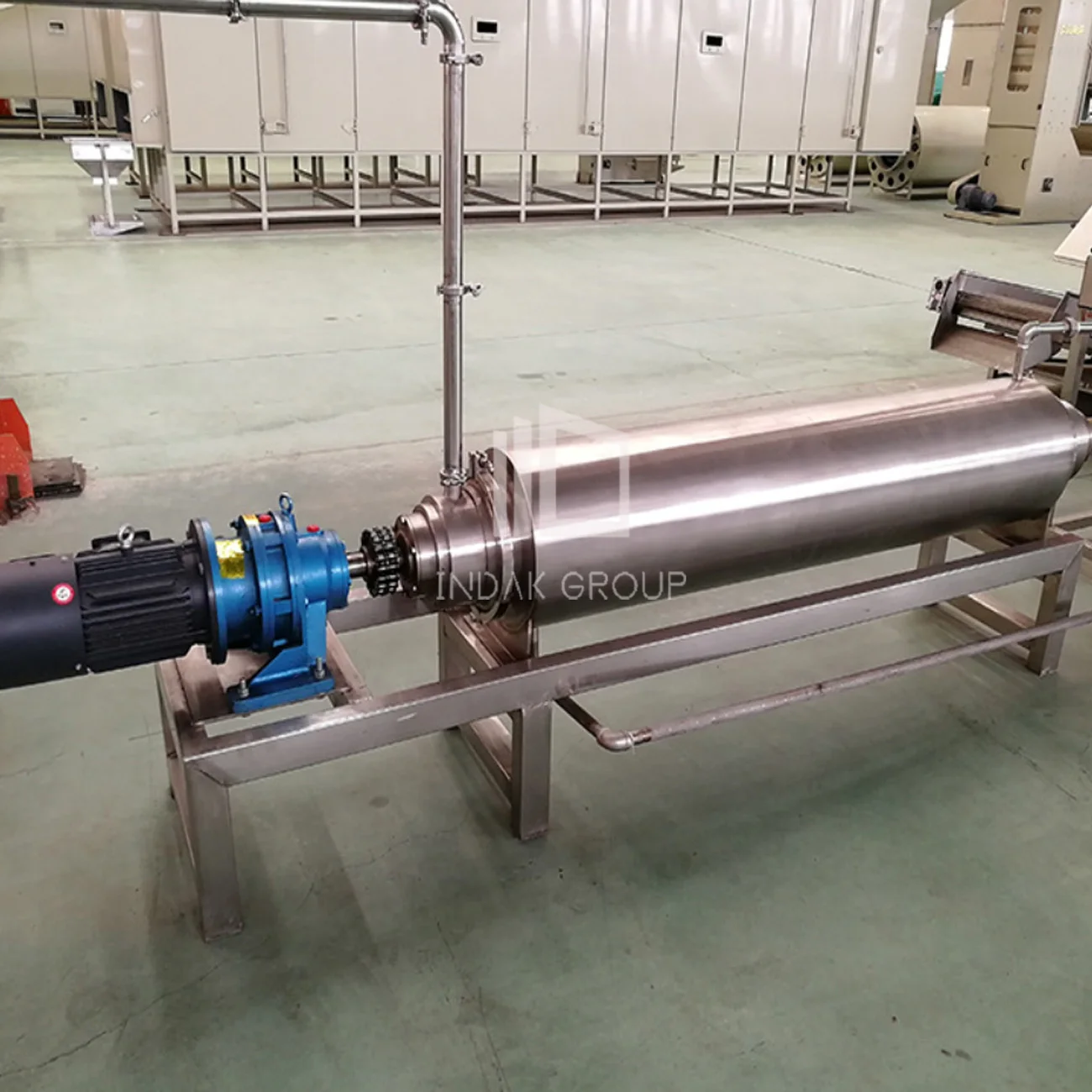

(10) peanut butter cooler

1 the process flow and main equipment of the production line include oven, peeling half granulator, picking belt, extractor, roughing mill, mixing tank, transfer pump, mixer, homogenizer, fine mill, vacuum tank, cooler, filling machine, etc. It is characterized by flow operation, high degree of mechanization, good performance and fully closed production. It is an equipment for producing stable peanut butter.

2 general equipment of peanut butter production line: oven, cooling belt, peeling machine, picking belt, roughing mill, ultra-fine mill, condenser, degassing tank and filling machine.

(1) Oven: bake peanuts.

(2) Cooling belt: the principle of extracting hot air by fan is used to cool the roasted peanuts.

(3) Peeling machine: peel the dried and roasted peanuts. During the peeling process, the peanuts are separated automatically to ensure the quality of the peeled peanuts.

(4) Picking belt: pick unqualified peanuts and some food residues.

(5) Roughing mill: the first grinding of peanuts.

(6) Superfine film: further grind the rough ground peanut to further improve the processing fineness.

(7) Condenser: cool the ground peanut butter.

(8) Degassing tank: degassing peanut butter before filling.

(9) Filling: filling and packaging.

(10) peanut butter cooler

Peanut is rich in fat and protein. After high temperature baking, taking off the red coat and grinding, it is made into original peanut butter, adding stabilizer to make stable peanut butter, and adding flavor materials to make flavor peanut butter.

According to the market demand, the core equipment of peanut butter production line, roughing mill and finishing mill, have been improved and optimized, and the processing fineness has been further improved. The complete set of equipment production line has high mechanization, good performance and fully closed production. It has the characteristics of simple operation, stable operation, low noise, easy maintenance, corrosion resistance, wide application and complete varieties

2 peanut butter production line can process high stable peanut butter, granular peanut butter and ordinary peanut butter. At the same time, it can also produce stable and ordinary sesame paste.

According to the market demand, the core equipment of peanut butter production line, roughing mill and finishing mill, have been improved and optimized, and the processing fineness has been further improved. The complete set of equipment production line has high mechanization, good performance and fully closed production. It has the characteristics of simple operation, stable operation, low noise, easy maintenance, corrosion resistance, wide application and complete varieties

2 peanut butter production line can process high stable peanut butter, granular peanut butter and ordinary peanut butter. At the same time, it can also produce stable and ordinary sesame paste.

SIMILAR PRODUCTS

Packing & Delivery

Company Profile

Inner Mongolia Yinda Trading Co., Ltd. We are a professional manufacturer of many kinds of machines, such as food machinery, agricultural machinery, Environment Protection Machinery and feed machinery.The waste recycling and handling machinery is our main project to promote in the worldwide.As a leading manufacturer of processing machines, we are selling and marketing the machines to many countries and regions in the world.Our motto is "based on quality, obtaining consumers satisfaction through honestly and credit, scientific and technical innovation, exceeding consumers expectation by strict management is our goal and long-termed work". We are looking forward to establishing relationships with you in the near future.

After-Sales

FAQ

1. Q: This is my first time to import, how can I get the machine?

A: After you confirm the machine to order and pay, we can help you to deliver the machine to your nearest seaport or airport, or door to door to you by express, etc., We are very experienced, please rest assured.

2.Q: What shall we do if breakdown occurs?

A: Please informed us once the breakdown occurs. During warranty period, if breakdown occurs,

we shall respond in time after receiving the notification of the buyer.

3. Q: What's the payment method?

A: We accept most of the payment method, such as, T/T, Western Union, Paypal, L/C, etc.

4.Q: Why choose us?

A: We can provide the machine with good quality and best price, also good and professional sale and after-sale service, if the machine has any problems in the future, we will provide the technical help and spare parts according to your need.

5.Q: Which ports do you usually ship at?

A: We can load container at: Qingdao, Shanghai, Tianjin, Shenzhen etc.

A: After you confirm the machine to order and pay, we can help you to deliver the machine to your nearest seaport or airport, or door to door to you by express, etc., We are very experienced, please rest assured.

2.Q: What shall we do if breakdown occurs?

A: Please informed us once the breakdown occurs. During warranty period, if breakdown occurs,

we shall respond in time after receiving the notification of the buyer.

3. Q: What's the payment method?

A: We accept most of the payment method, such as, T/T, Western Union, Paypal, L/C, etc.

4.Q: Why choose us?

A: We can provide the machine with good quality and best price, also good and professional sale and after-sale service, if the machine has any problems in the future, we will provide the technical help and spare parts according to your need.

5.Q: Which ports do you usually ship at?

A: We can load container at: Qingdao, Shanghai, Tianjin, Shenzhen etc.

Name Card

Похожие товары

Бытовая Машина Для Производства соевого молока

US $92.00-$102.00

Электрическая линия по производству арахисового масла из Турции

US $4000-$40000

Машина для производства соуса с перцем, кунжутом, арахисом, миндалем

US $520.00-$799.00