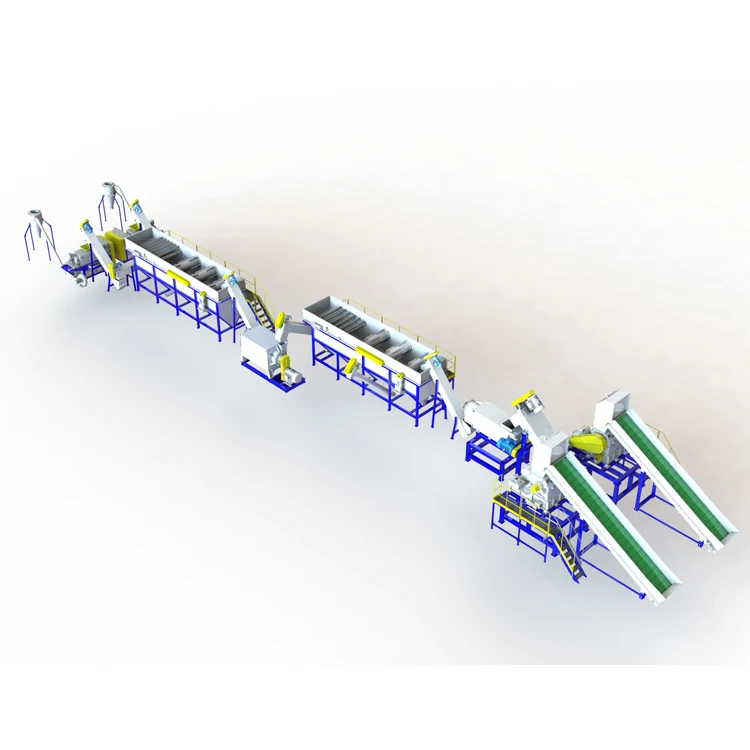

Машина для переработки пластмассы сельскохозяйственных отходов 1000 кг/ч

- Категория: Plastic Recycling Machinery >>>

- Поставщик: Zhangjiagang,City,Purui,Plastics&Rubber,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.64 $* | 0.33 $* |

| Aug-16-2025 | 0.25 $* | 0.17 $* |

| Jul-16-2025 | 0.64 $* | 0.12 $* |

| Jun-16-2025 | 0.34 $* | 0.56 $* |

| May-16-2025 | 0.14 $* | 0.47 $* |

| Apr-16-2025 | 0.57 $* | 0.92 $* |

| Mar-16-2025 | 0.85 $* | 0.44 $* |

| Feb-16-2025 | 0.64 $* | 0.65 $* |

| Jan-16-2025 | 0.42 $* | 0.10 $* |

Характеристики

Zhangjiagang City Purui Plastics&Rubber Machinery Co., Ltd.

Our company is a competitive manufacturer in the field of producing plastic recycling pelletizing machine.20 years focus on manufacturing one kind of machine-plastic pelletizing line.Such as two stage plastic granulator, double screen changer granulator, twin screw compounding granulator, PET bottle flakes pelletizing line etc.Our machines are specialized in processing PP PE HDPE LDPE BOPP PET PA PVC ABS PS EVA and so on. The Annual output of our production line are 90 sets.PURUI exported high quality machines to customers from various countries at the passed years, such as Germany, American, Holand, Sweden, Canada, Saudi Arabia, Egypt, Malaysia, Indonesia, Thailand, India etc.We insist on the following principles: continuous innovation on technique, strict quality control, perfect after-sale service and reasonable price.We believe that the quality is the soul of an enterprise. So we always put quality as the first consideration.

Final Products

Mechanical (centrifugal and squeezing) and thermal drying systems control the moisture content of the finished product.

At < 5% moisture the material is suitable for high quality pelletizing.

Product Description

Waste plastic recycling washing line for PP/PE Film and PP woven bag

The PE/PP Film system is designed for washing plastic films with contamination levels exceeding 80% Minimizing the recycling water flow rate and evaporation losses.

Application:

Agricultural films Recovered films from MSW or MRF's Films recovered from Landfills Post-industrial or post-consumer films Big bags (Raffia)

Application:

Agricultural films Recovered films from MSW or MRF's Films recovered from Landfills Post-industrial or post-consumer films Big bags (Raffia)

Products details

Plastic Crusher

To crush material into small sizes. With water to clean material and cool blades during crushing. Large materials are processed into small pieces in this module, which improves the washing result and makes the final product easy to packing.

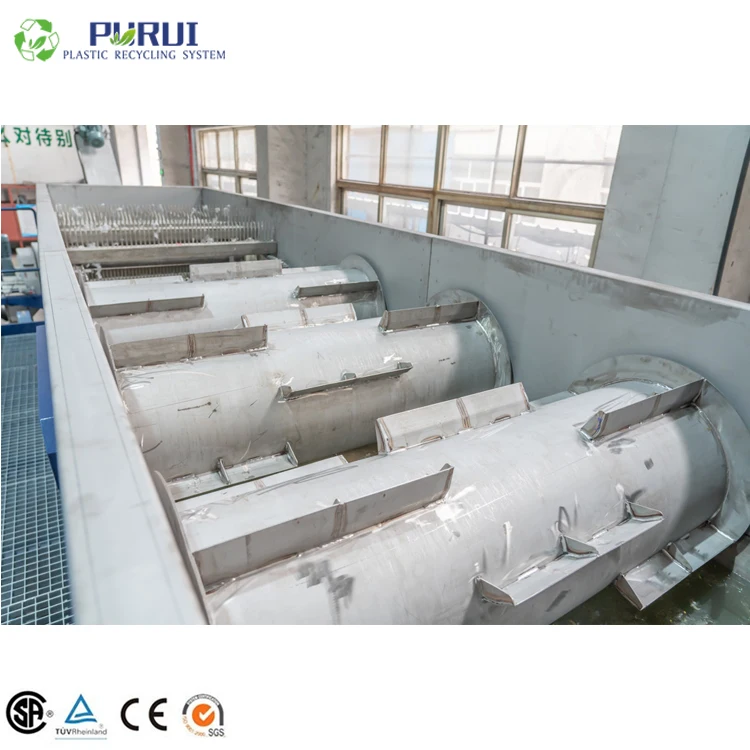

Dewatering machine

Mainly used for plastic recycling cleaning, when recycled material, because the material will stick with dirt (such as sand and dust, etc.), need to use friction cleaner for cleaning materials, cleaning process is typically through a friction washer material movement, make the friction material and sieve, so that the dirt off the material.

Floating washer tank

The discharge section using stainless steel claw type, outlet the material at the same time to reduce take out sewage. Matched bottom screw and side slag discharge screw, discharge precipitated impurities, the main body of the material using wheel form.

The discharge section using stainless steel claw type, outlet the material at the same time to reduce take out sewage.

Material: stainless steel

The discharge section using stainless steel claw type, outlet the material at the same time to reduce take out sewage.

Material: stainless steel

Floating washer tank

The discharge section using stainless steel claw type, outlet the material at the same time to reduce take out sewage. Matched bottom screw and side slag discharge screw, discharge precipitated impurities, the main body of the material using wheel form.

The discharge section using stainless steel claw type, outlet the material at the same time to reduce take out sewage.

Material: stainless steel

The discharge section using stainless steel claw type, outlet the material at the same time to reduce take out sewage.

Material: stainless steel

Floating washer tank

The discharge section using stainless steel claw type, outlet the material at the same time to reduce take out sewage. Matched bottom screw and side slag discharge screw, discharge precipitated impurities, the main body of the material using wheel form.

The discharge section using stainless steel claw type, outlet the material at the same time to reduce take out sewage.

Material: stainless steel

The discharge section using stainless steel claw type, outlet the material at the same time to reduce take out sewage.

Material: stainless steel

Plastic squeeze dryer

Through plastic squeeze dryer, water and volume of the materials can be squeezed to increase the quality of the pellets and the efficiency of the extruders. The moisture after squeeze dryer will be lowered down to 1-3%.

Product Paramenters

Production Line Parameter (for reference only, can be customized) | ||||||||

Capacity (kg/h) | Total Power (kw) | Area Required (㎡) | Labour Required | Water Consumption (m³/h) | ||||

300 | 210 | 240 | 3-4 | 1.5 | ||||

500 | 340 | 360 | 4-5 | 3 | ||||

1000 | 550 | 450 | 5-6 | 4.5 | ||||

1500 | 800 | 520 | 5-6 | 6 | ||||

Recommend Products

Why Choose Us

Zhangjiagang City Purui Plastics&Rubber Machinery Co., Ltd.

PURUI PLASTIC&RUBBER MACHINERY CO.,LTD was founded in 2006, the factory covers an area of 3000-5000 square meters.Specialized in plastic granulator, plastic washing, crushing and drying equipment production and research.Many years of experience and modern testing equipment ensure the quality of our customers' products.Puri meets all of these requirements with high quality, experienced and attentive service and achieves the successful development of the enterprise through sustainable profits.

Workshop.

Quality first is the tenet of our company.In order to realize this concept, we set up our own mold and CNC workshop, factory quality control personnel strictly control the quality.Also can facilitate the customer to better understand the production process and the physical machine.

Welcome friends from all walks of life to visit our workshop, sincerely hope that we can become partners and long-term cooperation in the future!

Certificates & Patents.

Our company has verification Certificates of equipments: CE Certificate , SGS.In addition to this,we also have many partners in the field of electronic components.For example,SIEMENS,WEQ,ORRON,HBM,GEFRAN,ETC.Our partners.

222

Exhibitions.

Packing&Delivery

FAQ

Q Are you a trading company or a manufacturer?

A We are a manufacturer and we can assure the quality of our machine.

Q What’s your guarantee or the warranty of the quality if we buy your machines?

A We have one year warranty of the spare parts free of charge. If any quality problems on our side occured in this period ,we will can do some replacement.

Q How can I install my machine when it arrives?

A We will send the instruction manual and videos to you,your workers can install the machine accorded as it.If you still have

problems in installing it and need our engineer to help,we will arrange our engineer to debugging the machine for you.At same time our engineer will give training lessons to labors in your factory.

Q How about the spare parts?

A During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If it is caused by your incorrect operations, we will provide the spare parts at cost price.

A We are a manufacturer and we can assure the quality of our machine.

Q What’s your guarantee or the warranty of the quality if we buy your machines?

A We have one year warranty of the spare parts free of charge. If any quality problems on our side occured in this period ,we will can do some replacement.

Q How can I install my machine when it arrives?

A We will send the instruction manual and videos to you,your workers can install the machine accorded as it.If you still have

problems in installing it and need our engineer to help,we will arrange our engineer to debugging the machine for you.At same time our engineer will give training lessons to labors in your factory.

Q How about the spare parts?

A During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If it is caused by your incorrect operations, we will provide the spare parts at cost price.

* Please do not hesitate to contact us if you would like to know more details about our products!