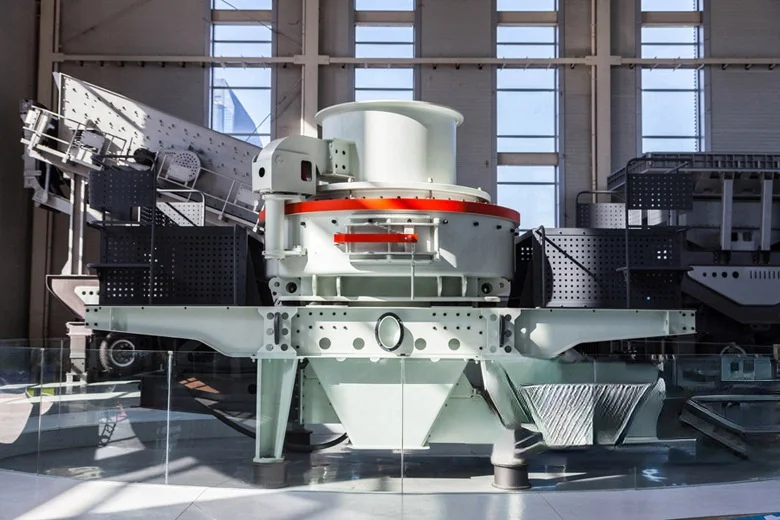

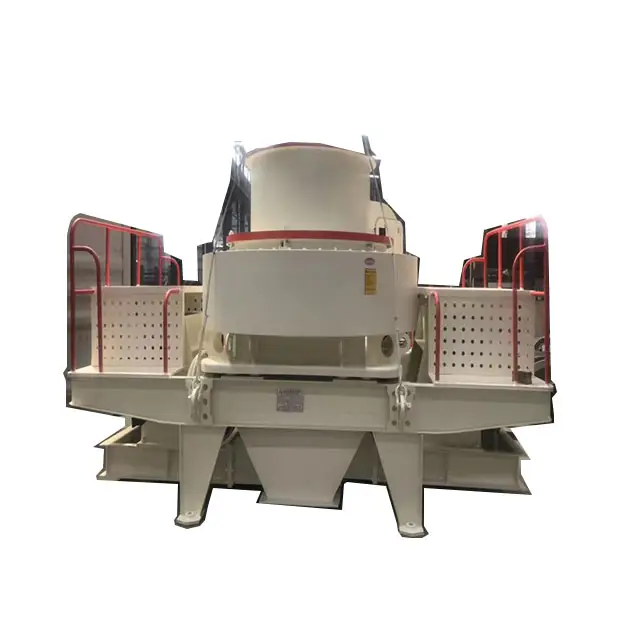

Крупногабаритное оборудование для производства песка известняка

- Категория: >>>

- Поставщик: Dongxing,Zhaoda,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-20-2025 | 55734.77 $* | 56849.94 $* |

| Jul-20-2025 | 45202.13 $* | 46106.86 $* |

| Jun-20-2025 | 54856.85 $* | 55953.91 $* |

| May-20-2025 | 54417.95 $* | 55505.6 $* |

| Apr-20-2025 | 43446.47 $* | 44315.84 $* |

| Mar-20-2025 | 53540.55 $* | 54611.88 $* |

| Feb-20-2025 | 53101.51 $* | 54163.75 $* |

| Jan-20-2025 | 52662.91 $* | 53715.93 $* |

Характеристики

| model | 5X7615 | 5X8522 | 5X9532 | 5X1145 | |

| Processing capacity (t/h) | Waterfall and feed | 150~280 | 240~380 | 350~540 | 500~640 |

| Full feed | 70~140 | 120~200 | 180~280 | 250~360 | |

| (mm) | Soft material | 35 | 40 | 45 | 50 |

| Hard material | 30 | 35 | 40 | 45 | |

| Speed (R / min) | 1700~1900 | 1500~1700 | 1300~1510 | 1100~1310 | |

| Double motor power (Kw) | 110~150 | 180~220 | 260~320 | 400~440 | |

| external dimensionsLength × Width × Height (mm) | 4100×2330×2300 | 4140×2500×2700 | 4560×2600×2900 | 5100×2790×3320 | |

| Weight (T) | 12.1 | 14.8 | 18.6 | 27.5 | |

| power supply | 380V,50Hz | ||||

| Thin oil lubrication station | Double oil pump motor power. | 2×0.25Kw | |||

| protective measures | Double oil complementary oil supply; automatic shutdown without oil flow; water cooling to cool down; winter motor heating start | ||||

| Fuel tank heating power | 2Kw | ||||

| Overall dimensions length×width×height (mm) | 820×520×1270 | ||||

| Lubrication system parameter table | ||||||

| Tank volume \t\t\t(L) | Rated pressure \t\t\t(Mpa) | flow \t\t\t(L/min) | power \t\t\t(kw) | Cooling water consumption \t\t\t(m3/h) | Electric heating voltage \t\t\t(V) | medium |

| 240 | 0.63 | 8 | 0.31 | ≥1.2 | 220 | Bearing oil 32-46# |

product description

The 5X sand-making machine is a new generation sand-making machine developed with the aim of improving energy utilization rate, reducing wear rate, prolonging maintenance cycle, reducing maintenance time, improving crushing efficiency and control level. It has the characteristics of energy saving, high output, high energy utilization rate, excellent product grain shape, convenient maintenance and repair, wide application, etc., and meets the needs of modern sandstone production.

The 5X sand-making machine is a new generation sand-making machine developed with the aim of improving energy utilization rate, reducing wear rate, prolonging maintenance cycle, reducing maintenance time, improving crushing efficiency and control level. It has the characteristics of energy saving, high output, high energy utilization rate, excellent product grain shape, convenient maintenance and repair, wide application, etc., and meets the needs of modern sandstone production.

Limestone sand making EPC project

[Processing materials]: Limestone [Output]: 500T/H

[discharge particle size]: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

[customer information]:The customer is a concrete company of a large group, with its own cement plant, power plant, etc. The processing material is purchased limestone, and the finished product is used in its own concrete mixing plant, and it is also exported to Weifang and other places. Our company provides process flow charts, EPC services such as on-site measurement, design plan, installation and foundation guidance, and technical support.

PE1200×1500 jaw crusher is transported by FH1860 vibrating feeder for primary crushing, then screened by S5X2160-2 vibrating screen, and then transported by HST250S1 single cylinder cone crusher for secondary crushing. The crushed materials enter CI5X1520 impact crusher for tertiary crushing, and the crushed materials are transported by FH1245 vibrating feeder to VSI5X1145 sand making machine for sand shaping, and then passed through four 4YK3X2675.

River pebble sand production line

[Processing materials]: River Pebble [Output]: 220-250T/H

[feed granularity]: <300mm & nbsp; [Discharge granularity]: 0-4.75 mm.

[Customer situation]:

After fully understanding the site and rigorously discussing with the other engineers, the design plan of the two sand making production lines was determined. HST single-cylinder hydraulic cone crusher has large feed size, low power and high production efficiency, which can basically replace coarse crushing. The product produced by the 5X centrifugal sand making machine has good grain shape, reasonable gradation, and adjustable fineness modulus. It is an ideal choice for machine-made sand and stone.

The raw materials are uniformly and continuously sent to two HST160(S2) single-cylinder hydraulic cone breakers for primary crushing, and the crushed materials enter two 5X1145 centrifugal sand mills for secondary crushing. The discharged materials are screened by four YZS2160 circular vibrating screens, and the unqualified materials are returned to the sand mills for secondary crushing. After being washed by four XSD3016 sand washers, clean aggregates are finally obtained.

We have domestic large equipment manufacturing base and more than 150 sets of various production and processing equipment, as well as our own machining workshop, electrical workshop and commissioning workshop

For equipment production, the quality plan, production and process control plan shall be prepared to clarify the implementation provisions of key processes, special processes and process procedures, and timely guide and correct the process procedures, processing and assembly points and requirements in the production process, so as to realize the accurate realization of products from drawings to reality

The mature processing technology and quality plan have solved the worries of customers' equipment failure, sufficient purchase and inventory, production plan control and management of the processing quality and progress of the entire set of equipment.