Хит продаж камнедробилка гарантированного качества оборудование для горной промышленности камнедробилки дробления

- Категория: Crusher >>>

- Поставщик: Sichuan,Beno,Energy,Saving,And,Environmental,Protection,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.33 $* | 0.52 $* |

| Aug-16-2025 | 0.71 $* | 0.20 $* |

| Jul-16-2025 | 0.73 $* | 0.31 $* |

| Jun-16-2025 | 0.72 $* | 0.97 $* |

| May-16-2025 | 0.75 $* | 0.38 $* |

| Apr-16-2025 | 0.3 $* | 0.44 $* |

| Mar-16-2025 | 0.88 $* | 0.93 $* |

| Feb-16-2025 | 0.54 $* | 0.35 $* |

| Jan-16-2025 | 0.86 $* | 0.93 $* |

Характеристики

Product Description

Equipment Advantages

Structure & Main Features

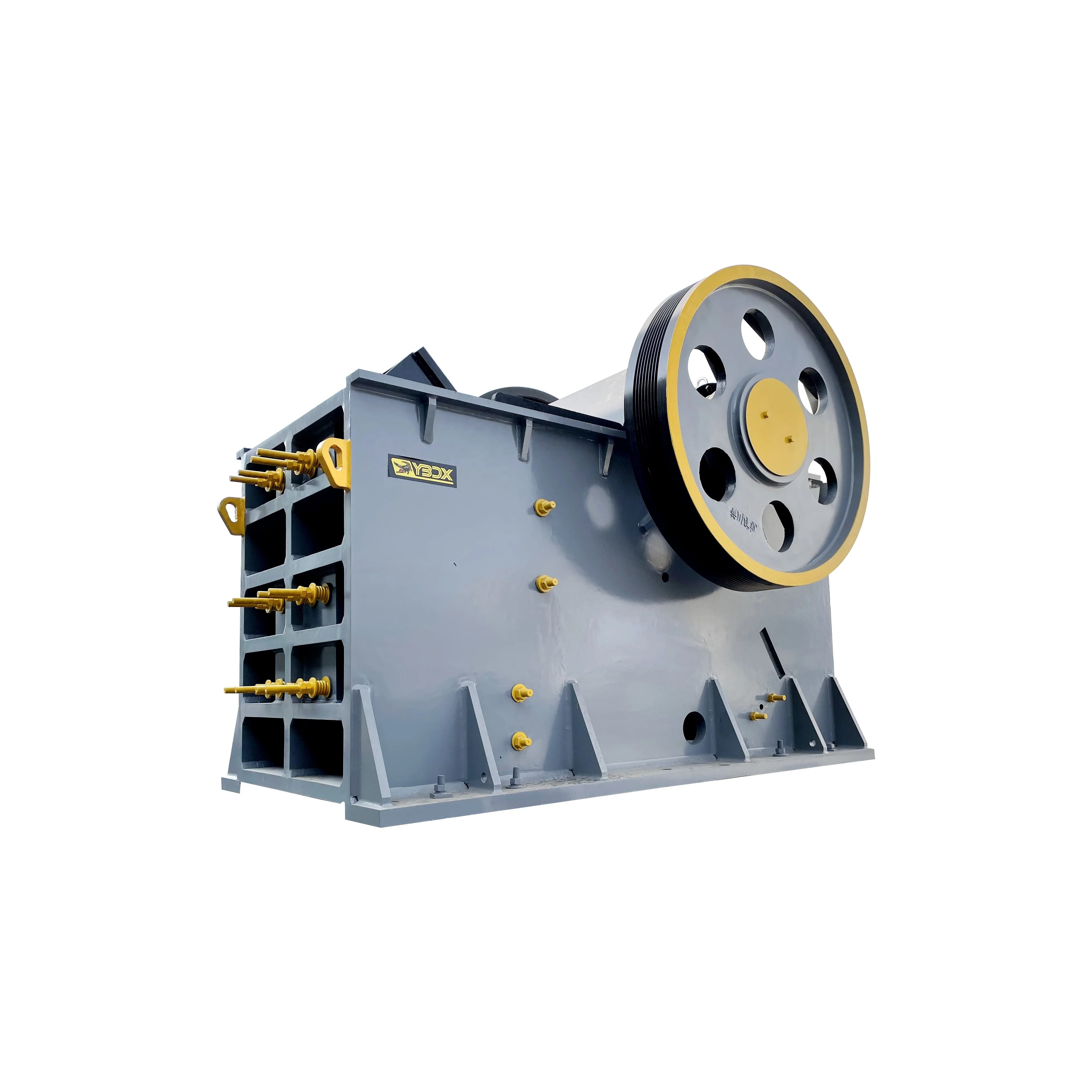

The jaw crusher is mainly composed of frame, eccentric shaft, movable jaw body assembly, tooth plate, guard plate, adjusting seat, elbow plate, tie rod spring, pulley, motor and other components.

①Wide range of applications, mainly used for crushing hard rocks, to meet all kinds of more demanding coarse and fine crushing operations.

②Stable and reliable performance, the machine frame and wear parts are made of high-quality steel plates and wear-resistant alloys, which have strong resistance to pressure, load and blow during operation. The optimized design of crushing trajectory with large eccentric distance improves the output and crushing ratio, so that the crushing efficiency is guaranteed, the operation is more stable and the output is higher.

③Low production cost, the main wear parts tooth plate and guard plate are made of wear-resistant alloy in order to better wear resistance and long service time. Tooth plate design can be installed to extend the use of time and tooth shape according to different material requirements can be customized to the best crushing tooth shape, improving the finished product rate. In addition, independent research, development patent environmental protection and energy-saving supporting products can reduce the equipment motor power of about 40%.

④Diversified optional configurations, the machine as a wide range of powerful classic primary crushing equipment, after years of practice combined with the current production process needs, has developed a variety of configuration items to meet the different requirements of use. The host is divided into fixed and a variety of mobile or portable installation options. The motor is divided into integrated or separate installation options. Adjustment device can be divided into mechanical adjustment method (double pull block or gasket adjustment, optional), hydraulic adjustment method (with hydraulic oil station, PLC automatic control system, etc.). Auxiliary parts are optional crusher section energy storage, belt pulley and drive safety guard, mainframe bottom plate with rubber shock absorption device, etc.

①Wide range of applications, mainly used for crushing hard rocks, to meet all kinds of more demanding coarse and fine crushing operations.

②Stable and reliable performance, the machine frame and wear parts are made of high-quality steel plates and wear-resistant alloys, which have strong resistance to pressure, load and blow during operation. The optimized design of crushing trajectory with large eccentric distance improves the output and crushing ratio, so that the crushing efficiency is guaranteed, the operation is more stable and the output is higher.

③Low production cost, the main wear parts tooth plate and guard plate are made of wear-resistant alloy in order to better wear resistance and long service time. Tooth plate design can be installed to extend the use of time and tooth shape according to different material requirements can be customized to the best crushing tooth shape, improving the finished product rate. In addition, independent research, development patent environmental protection and energy-saving supporting products can reduce the equipment motor power of about 40%.

④Diversified optional configurations, the machine as a wide range of powerful classic primary crushing equipment, after years of practice combined with the current production process needs, has developed a variety of configuration items to meet the different requirements of use. The host is divided into fixed and a variety of mobile or portable installation options. The motor is divided into integrated or separate installation options. Adjustment device can be divided into mechanical adjustment method (double pull block or gasket adjustment, optional), hydraulic adjustment method (with hydraulic oil station, PLC automatic control system, etc.). Auxiliary parts are optional crusher section energy storage, belt pulley and drive safety guard, mainframe bottom plate with rubber shock absorption device, etc.

Product Recommendation

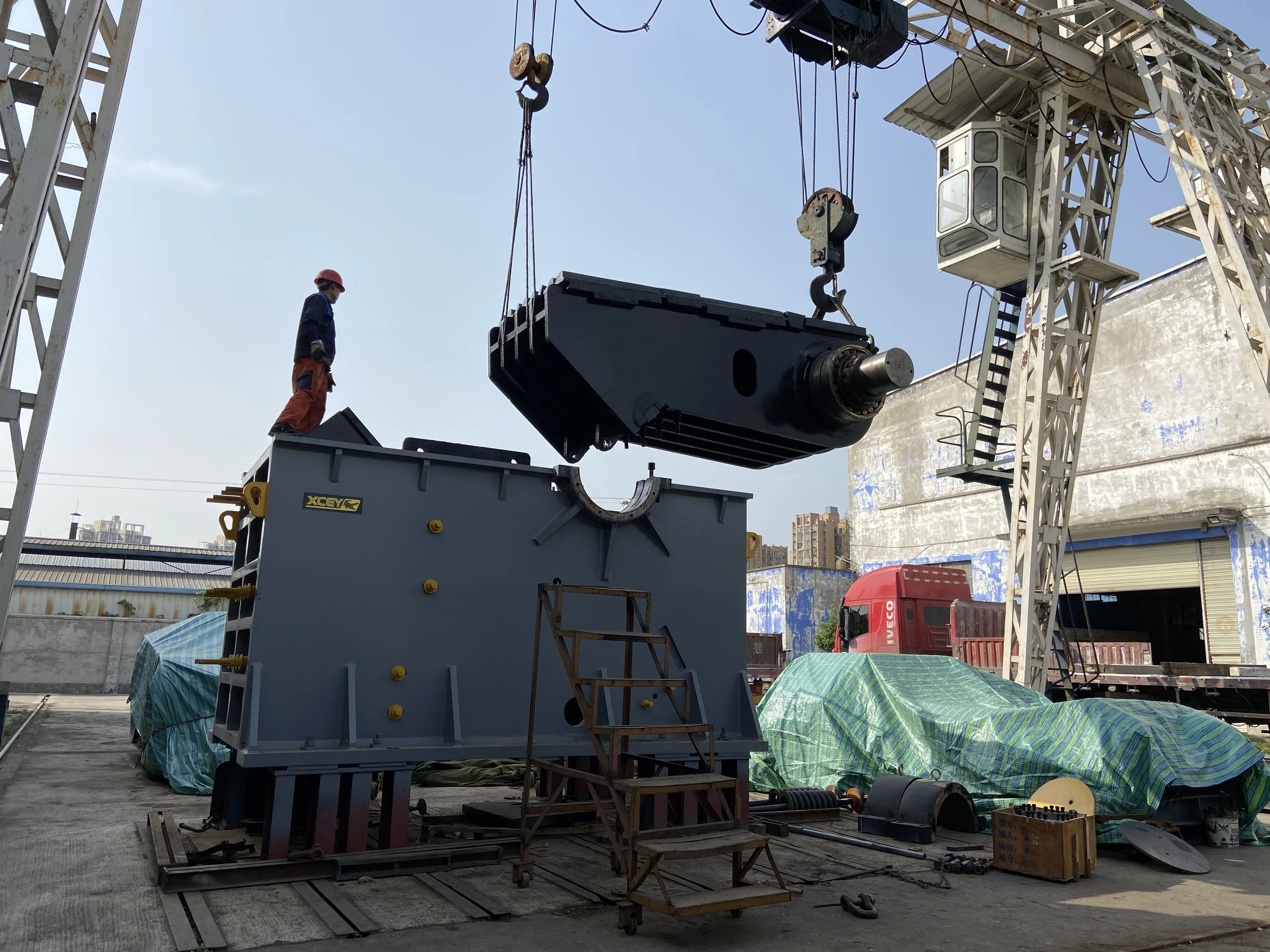

Production Process

Exhibition

Company View

Packing&Transportation

FAQ

1. How long is the construction period?

As appropriate, about 15 to 60 days.

As appropriate, about 15 to 60 days.

2. What are the components of wear-resisting parts?

Mn13Cr2, Mn18Cr5, Alloy.

Mn13Cr2, Mn18Cr5, Alloy.

3. How long is wear-resisting parts quality guarantee period?

As appropriate, about 200-6000 working hours.

As appropriate, about 200-6000 working hours.

4. How to install?

Customers shall install by themselves and we provide installation instructions.

Customers shall install by themselves and we provide installation instructions.