Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-20-2025 | 51576.13 $* | 52608.60 $* |

| Jul-20-2025 | 41829.79 $* | 42666.47 $* |

| Jun-20-2025 | 50764.21 $* | 51779.9 $* |

| May-20-2025 | 50358.12 $* | 51365.3 $* |

| Apr-20-2025 | 40205.43 $* | 41009.49 $* |

| Mar-20-2025 | 49545.38 $* | 50536.47 $* |

| Feb-20-2025 | 49139.24 $* | 50122.30 $* |

| Jan-20-2025 | 48733.8 $* | 49708.76 $* |

Характеристики

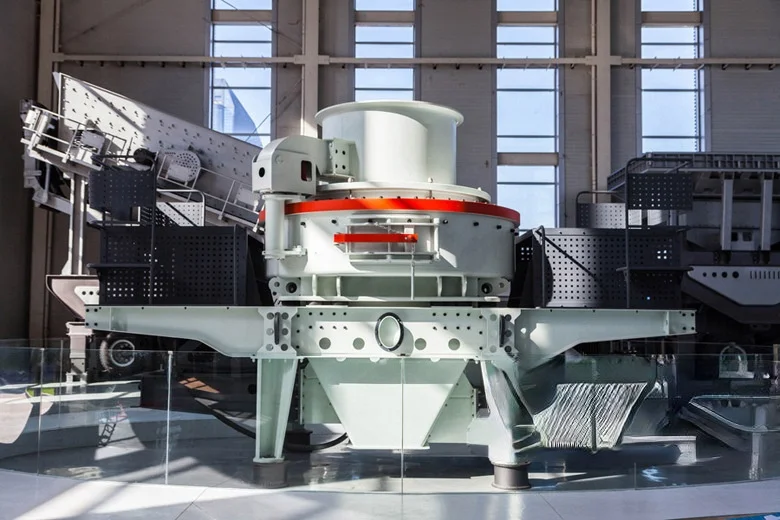

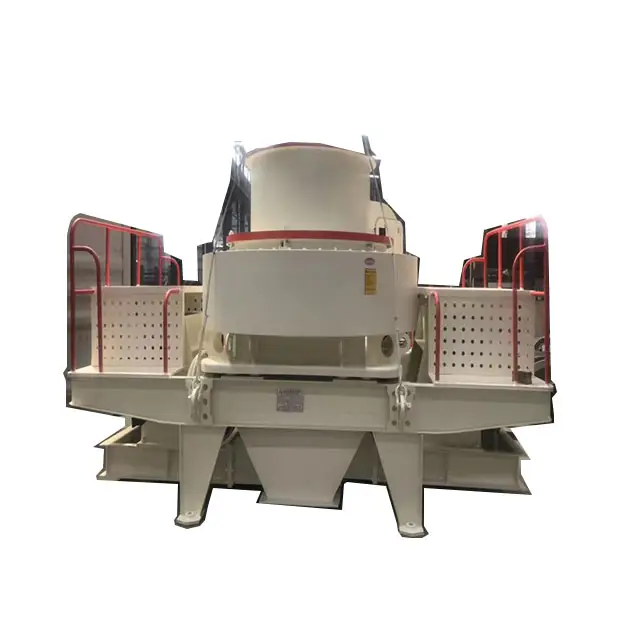

VSI6X Series Vertical Shaft Impact Crusher, with both gravel and machine-made sand production functions

New four-wheel design, higher material passing rate and greater output

"Stone hits stone" working principle, reduce equipment wear and tear, longer service life

VSI6X series vertical shaft impact crusher is a new type of sand making and crushing equipment with multiple patented technologies, absorbing many years of research and development experience and technical concepts, adopting a new four-port impeller design structure and special sealing structure bearing cylinder oil leakage and other technologies. The characteristics of long life and wide application have helped Dashachang gradually move towards large-scale and centralized production to meet the requirements for green development and production capacity.

Cobblestone sand production line

Cobblestone sand production line

【Processing materials】: Cobblestone 【Discharge size】: 0-4mm 【Output】: 200T/H

【Production status】:The materials are sent to the HPT300 hydraulic cone crusher for preliminary crushing. After being screened by the vibrating screen, the unqualified materials are returned to the cone crusher for re-crushing. The qualified materials are sent by the belt conveyor to two VSI6X1040 sand making machines for secondary crushing. After screening again, the qualified materials are sent to the finished product pile by the belt conveyor, and the unqualified materials are returned to the sand making machine for crushing until they are qualified.

The finished products of the pebbles processed by the VSI6X sand making machine will be used in concrete mixing plants, dry-mixed mortar plants and other fields for local infrastructure construction.

Cobblestone Sand EPC Project

Cobblestone Sand EPC Project

【Processing materials】: Cobblestone 【Output】: 500-600T/H

【Inlet particle size】: ≤200mm 【Discharge particle size】: 0-5mm

【Production status】:

The project started in March 2019 and was completed and put into production in July. Since the raw material is river pebbles ≤200mm and the raw sand content is relatively high, the production process adopts first screening. The raw sand is screened through 3 sets of S5X2760-3 vibrating screens to directly produce the finished product, and the material above 5mm is passed through 3 sets of HPT300 cones. After crushing, the crusher is screened by a S5X2460-3 vibrating screen. ≤40mm enters 3 VSI6X1263 sand making machines for sand making and then is screened by 3 S5X3075-3T vibrating screens. Materials above 40mm are returned to the sand making machine for buffer cycle crushing.

New design, efficiency

The impeller structure adopts a new four-port design, and the material throughput is about 20% compared with the same material of the three-port impeller.

Process upgrade, cost reduction and efficiency increase

Using the "stone hitting stone" working mode to reduce the types of wear resistance and reduce customer production costs; the structure and technology of the impeller part are adjusted, and the service life of the impeller part is about 30~200% compared with the previous equipment under the condition of crushing the same material.

Special design, quality

Special design, quality

The transmission part of the equipment adopts a special sealed structure for oil leakage; the bearing adopts imported bearings to reduce the failure of the transmission system.

Easy to maintain, stable operation

The newly-added lifting device is convenient for customers to maintain the equipment, and the maintenance saves labor and effort; the simple structure design of the lower body will block the lower part of the body when the material water content is too large, reducing downtime and stable operation.

| Model | Sand making | Sand making | (r/min) | power \t\t\t(kw) | ||

| (mm) | Throughput (t/h) | |||||

| VSI6X1263 | ≤50 | ≤60 | 454-486 | 545-583 | 900-1200 | 315×2 |

| VSI6X1150 | ≤45 | ≤55 | 344-368 | 413-442 | 1000-1300 | 250×2 |

| VSI6X1040 | ≤40 | ≤50 | 264-283 | 317-342 | 1100-1400 | 200×2 |

| VSI6X9026 | ≤35 | ≤45 | 167-179 | 200-215 | 1200-1500 | 132×2 |

| VSI6X8018 | ≤30 | ≤40 | 109-117 | 131-140 | 1300-1700 | 90×2 |