Китайская новая мобильная дробильная станция для гусеничного грунта дробилка по самой низкой цене сколько стоит

- Категория: >>>

- Поставщик: Dongxing,Zhaoda,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.7 $* | 0.7 $* |

| Aug-20-2025 | 0.62 $* | 0.1 $* |

| Jul-20-2025 | 0.62 $* | 0.75 $* |

| Jun-20-2025 | 0.16 $* | 0.64 $* |

| May-20-2025 | 0.71 $* | 0.25 $* |

| Apr-20-2025 | 0.90 $* | 0.0 $* |

| Mar-20-2025 | 0.24 $* | 0.75 $* |

| Feb-20-2025 | 0.1 $* | 0.54 $* |

| Jan-20-2025 | 0.41 $* | 0.88 $* |

Характеристики

product

productPowerful processing capacity, full of Nissan, all on-board electronic control systems

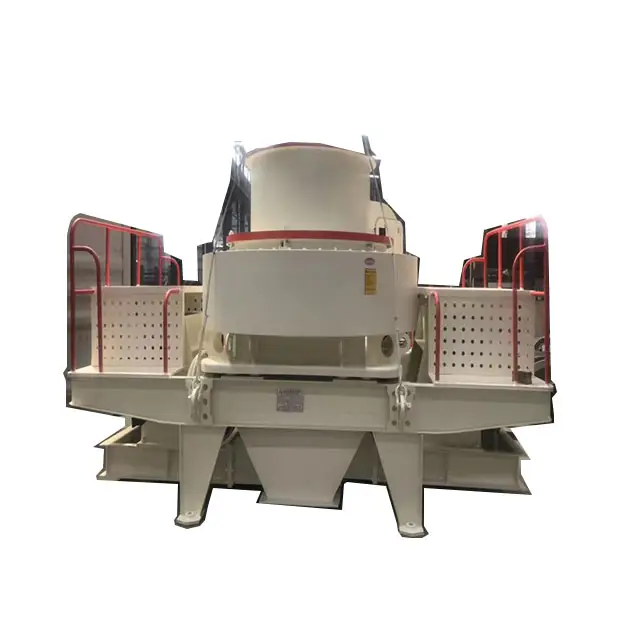

K3 series mobile production line is a tire-type mobile production line specially designed for small and medium production lines (100-300T). It is suitable for the crushing, screening and sand making operations of various soft rock, hard rock, and construction waste. This equipment has a total of 14 product line models, and 5 frames are equipped with 19 standard mobile equipment modules. The characteristics of the mobile production line are: mature host equipment, fast assembly line to meet operating needs, modular and simple installation, overall flexible movement, standardization and generalization, etc.

working principle:

The main equipment of the K3 series mobile production line is: GF series feeder, C6X series jaw crusher, CI5X series impact crusher, HPT/HST series cone crusher, S5X series vibrating screen, VSI6X series sand making machine, The speed and power are full and strong, and the project operation production capacity is strong, which is more stable and reliable.

The mobile production line usually uses an external electric power source as the power source. The raw materials are evenly sent to the C6X series jaw crusher or the CI5X series impact crusher by the GF series vibrating feeder for coarse crushing operation, and the coarsely crushed materials are conveyed by the belt conveyor. It is sent to the cone crusher or impact crusher for further crushing. The finely crushed material is transported to the S5X series vibrating screen for screening. The material with the required particle size of the finished product is output by the finished product conveyor belt to be the finished product; the unfinished product requires the particle size of the product. The material returns from the vibrating screen to the sand making machine or cone crusher for reprocessing, forming a closed loop for multiple cycles. The granularity of the finished product can be combined and classified according to the needs of users.

The material with the required particle size of the finished product is returned from the vibrating screen to the sand making machine or cone crusher for reprocessing, forming a closed circuit for multiple cycles. The granularity of the finished product can be combined and classified according to the needs of users

Customer case::

Granite mobile crushing production line

【Processing materials】: Granite 【Output】: 200T/H

【Inlet particle size】: 0-720mm 【Discharge particle size】: 0-31.5mm

【Production status】:The project is located in a special economic zone of China, adopts two-stage crushing and closed circuit return material screening, which is a conventional and typical hard rock crushing production line. The selected equipment is the upgraded K3 series coarse crushing mobile station and the well-known K2 series medium and fine crushing and screening mobile station, which is flexible and can be quickly assembled to meet the needs of large cities for transition and operation.

The 720mm granite material enters the K3C110-1 coarse crushing mobile station for one stage of crushing. The coarsely crushed material is sent to the KH300-2 medium and fine crushing and screening mobile station by a belt conveyor for further crushing. The finished product with a particle size of 31.5mm is conveyed by the finished product conveyor belt. The output is the finished product, and the material less than 31.5mm is returned from the vibrating screen to the mobile station for reprocessing, forming a closed loop.

The 720mm granite material enters the K3C110-1 coarse crushing mobile station for one stage of crushing. The coarsely crushed material is sent to the KH300-2 medium and fine crushing and screening mobile station by a belt conveyor for further crushing. The finished product with a particle size of 31.5mm is conveyed by the finished product conveyor belt. The output is the finished product, and the material less than 31.5mm is returned from the vibrating screen to the mobile station for reprocessing, forming a closed loop.

Product advantages:

Powerful processing capacity, full daily production

Large-size grate feeder: In mainstream 200-300 tons projects, the GF1245 type feeder is equipped with a double-layer grate with a length of 1800mm. It has the functions of dividing small materials and removing soil, and has a strong processing capacity.

Large-volume silo: the feed silo volume of coarse crushing equipment is 6.5m?, the widened feeding baffle can reach 8m?, the transfer feeding silo volume of medium crushing equipment is 4.5m?, with certain intermediate transfer storage function, adjustable speed Feeding, and continuous feeding, the daily output is full.

The whole series of on-board electronic control system

The electronic control system has a built-in remote start-stop operation port. After the user prepares remote low-voltage accessories, it can control the room's day and night monitoring operations in harsh environments such as high temperature exposure, wind and rain, and freezing ground. The indoor central control system has a low-end keyboard console and optional PLC LCD screen console.

Free of concrete foundation, free of disassembly and assemblyThe operation site only needs to be flat and compacted to be energized for operation, without the need for hardening of the cement foundation, which can greatly reduce the cost of project infrastructure construction materials and the installation cost of on-site accessories. The whole series can realize land transportation without disassembly and assembly (including shoes), and sea container transportation.

Quickly enter operation mode

Quickly enter operation mode

The standard shoes are stowed during transportation transition. After entering the operation site, the electronically controlled hydraulic outriggers are extended to quickly enter the operation mode and have the function of fast folding and transition. The vehicle-mounted belt conveyor is retracted and contracted during transportation, and immediately enters the feeding operation mode after it is deployed on the spot.

Electronic control system, reliable and economical

All electronic control systems are standard (Delixi/Chint brand) supply status, reliable and economical. The electronic control system is equipped with a remote start-stop operation terminal interface. After the user prepares remote low-voltage accessories, it can control the room day and night monitoring operations in harsh environments.

Sieving first and then crushing, large capacity for small modelsThe medium crushing mobile equipment has a unique style of crushing and discharging direction design. In the case of a large amount of raw materials, it can start the sieving first and then crushing operation mode, and the small size and large capacity are surprisingly winning treatment effects.

Multiple seals and dustproof, practice the concept

The car belt conveyor has reserved tarpaulin installation holes, which can be equipped with a dust cover for receiving and discharging materials, and a mobile tarp canopy can also be equipped for special needs. K3 is equipped with 100, 150-ton all-in-one production line mobile equipment, coarse and medium crushing equipment, screening equipment and belt conveyors are integrated in a single machine, and the whole process is operated in a small site. The dust control effect is good, and it is light and flexible.

Semi-mobile sled production line model

If the work site does not move frequently (more than one year), the tire chassis may not be selected in the mobile equipment module, and the entire mobile production line will become a semi-mobile sled production line, which can greatly save investment costs.

Versatility and strong scalability

The K3 series of 200-ton mobile equipment also plays the role of a battle group member of 300-ton and 400-ton mobile equipment. In the 300-ton and 400-ton crushing and sand making process system, it exerts general mobile equipment and strong expansion capabilities. Characteristics.

about us:

Equipment production through the preparation of quality plans, production and process control plans, clarify the implementation of key procedures, special procedures and process regulations, and promptly give correct guidance and corrections to the process regulations, processing and assembly essentials and requirements during production operations, So as to realize the accurate realization of the product from drawing to reality.

The mature processing technology and quality plan have solved the customer's worries about equipment failure. Sufficient procurement and inventory, and production plan control have managed the processing quality and progress of the entire set of equipment.

After-sales service Service is boundless, pleased with heart:

From planning the site to design drawings, from technical training to installation and commissioning; from large production lines to small gears, no matter where you are, you only need to consult us or an email, and you will get it within 24 hours Our response and help.