Машина для изготовления конвертов из воздушных пузырчатых пакетов машина

- Категория: Bag Making Machines >>>

- Поставщик: Zhengzhou,Share,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 54383.77 $* | 57102.32 $* |

| Aug-20-2025 | 53926.28 $* | 56622.26 $* |

| Jul-20-2025 | 45243.99 $* | 47505.63 $* |

| Jun-20-2025 | 53012.21 $* | 55663.82 $* |

| May-20-2025 | 46157.25 $* | 48465.27 $* |

| Apr-20-2025 | 52098.57 $* | 54703.49 $* |

| Mar-20-2025 | 51641.19 $* | 54223.30 $* |

| Feb-20-2025 | 51184.12 $* | 53743.74 $* |

| Jan-20-2025 | 50727.20 $* | 53263.31 $* |

Характеристики

Products Description

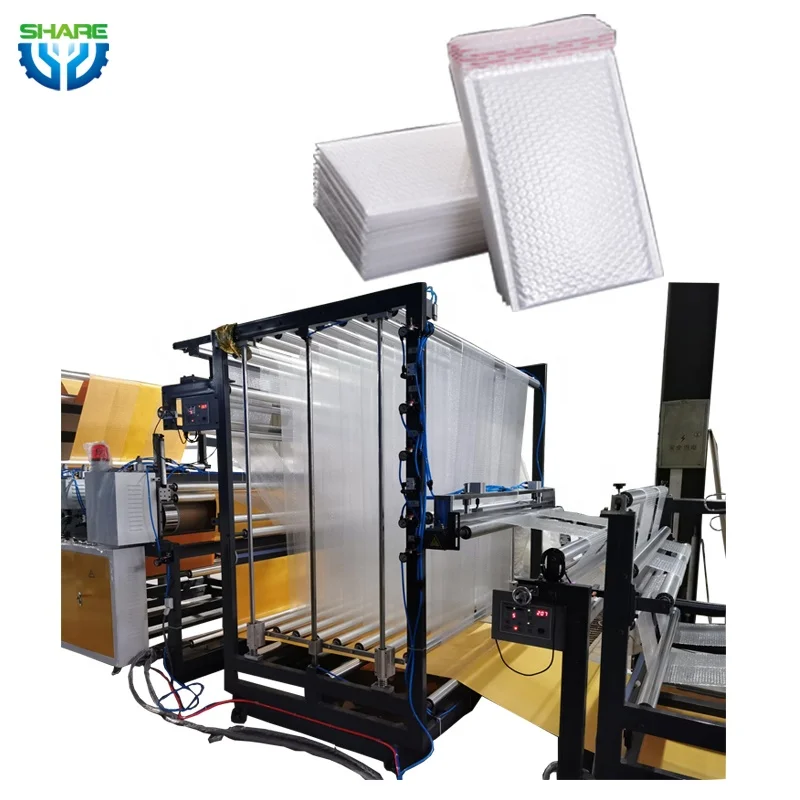

Bubble bag making machine courier delivery bag Kraft paper air bubble film bag making machine

This machine is specially used to produce bubble film envelope bags, suitable for pearlescent film, aluminized film, co-extrusion film, cast bubble film and other materials, (single fold or double fold) forming, cross-sealing by hot pressing, and cutting by cutter Finished products into envelope bags. The whole machine adopts Widow computer control, man-machine interface, servo motor for traction, uniform feeding speed synchronization, photoelectric correction, easy operation, counting segmentation, automatic stop when label is lost, automatic stop when lack of material, and manual feeding without stopping. The cutter can be moved and other functions, the operation is stable, the envelope bag made is flat and beautiful, and the adhesion is strong and reliable

Details Images

Model | 800 double-outlet envelope bag making machine with compound bubble film |

Applicable material | Coated kraft paper, aluminized film, co-extrusion film, pearlescent film, or aluminized film, etc. |

Bag making speed | 30-120 pcs/min (Can be split in two when the bag length is less than 380 mm) |

Maximum sealing length | 780 mm |

Maximum bag making width | 600 mm |

Maximum raw material roller width | 1550 mm |

Maximum raw material roller diameter | Bubble film 1400 mm |

Machine size | 24000*2200*2300 mm(L*W*H) |

Machine weight | 7000 kg |

Whole machine power | 32 kw |

Voltage | Three-phase four-wire AC 380V 50HZ |

Gas source | 5-10kg/cm2 |

Main machine configuration

1. Computer main control: Multi-dimensional motion controller is used as the main control of the whole machine, 7-inch touch man-machine interface, two AC servo fixed-length, with automatic counting, early warning, number stop, number display, high parking, etc. Function. The main engine adopts Taiwan brand speed reducer with brake motor

2. Material drawing method: fixed length adopts double servo material drawing method, two sets of servo fixed length drawing material, combined belt rubber roller pressing.

3. Forming device: The composite material is folded in half by a double-folding roller. Roll in half

4. Sealing and forming device: adopts mechanical down-drawing forming method,

Equipped with four sets of 20mm wide line horizontal sealing devices (one set of cold-pressing shaping device, one set of self-circulating water cooling system), and one set of pneumatic needle exhaust device.

5. Feeding part: It adopts active follow-up feeding, and the feeding speed is adjusted by domestically produced loss-of-quantity frequency conversion speed, with a decelerating motor.

6. Equipped with double-station self-adhesive strip gluing device

7. Unwinding part: adopt photoelectric correcting and unwinding, and the brake device is pneumatic pressure adjustable.

8. A set of mechanical heavy-duty cold cutters can cut off the sealed bag instantly when sealing.

9. Equipped with a set of domestic marking electric eye tracking device.

10. Equipped with a set of belt conveying and rewinding device.

11. Equipped with a set of hot-melt glue double-head glue spraying device (domestic), which can spray glue continuously.

12. A set of tooth-shaped cold press cutters are delivered separately (fine teeth and wide teeth are optional)

2. Material drawing method: fixed length adopts double servo material drawing method, two sets of servo fixed length drawing material, combined belt rubber roller pressing.

3. Forming device: The composite material is folded in half by a double-folding roller. Roll in half

4. Sealing and forming device: adopts mechanical down-drawing forming method,

Equipped with four sets of 20mm wide line horizontal sealing devices (one set of cold-pressing shaping device, one set of self-circulating water cooling system), and one set of pneumatic needle exhaust device.

5. Feeding part: It adopts active follow-up feeding, and the feeding speed is adjusted by domestically produced loss-of-quantity frequency conversion speed, with a decelerating motor.

6. Equipped with double-station self-adhesive strip gluing device

7. Unwinding part: adopt photoelectric correcting and unwinding, and the brake device is pneumatic pressure adjustable.

8. A set of mechanical heavy-duty cold cutters can cut off the sealed bag instantly when sealing.

9. Equipped with a set of domestic marking electric eye tracking device.

10. Equipped with a set of belt conveying and rewinding device.

11. Equipped with a set of hot-melt glue double-head glue spraying device (domestic), which can spray glue continuously.

12. A set of tooth-shaped cold press cutters are delivered separately (fine teeth and wide teeth are optional)

Main component parts

1.motion controller-CHINA

2.Main motor 3.7kw -Taiwan brand

3.Servo Motor 3.7kw - two sets CHINA

4. INVERTER -DELIXI

5. Main frequency conversion 3.7KW. Two small 0.4kw

3.Servo Motor 3.7kw - two sets CHINA

4. INVERTER -DELIXI

5. Main frequency conversion 3.7KW. Two small 0.4kw

Free parts

1 : Manual 1copy

2 : Hardware tools 1set

3 :Oil kettle 1piece

4 :Thermocouple 5pcs

5 :Heating tube 4pcs

6 : TEFLON 2meter

7 : Nylon gear 4pcs

9 : Blade sharpener 5pcs

10 : Machine pad 24pcs

11 :Cutter adjuster 1set

12 : One main cutter

3 :Oil kettle 1piece

4 :Thermocouple 5pcs

5 :Heating tube 4pcs

6 : TEFLON 2meter

7 : Nylon gear 4pcs

9 : Blade sharpener 5pcs

10 : Machine pad 24pcs

11 :Cutter adjuster 1set

12 : One main cutter

Unwinding rack with magnetic powder tension automatic tension control

Bubble storage system , can realize manual feeding without stopping the machine

Paper laminate heat compounding station heat by oil

Folding station which Can fold one side or fold two side to make two pcs one time

Heating sealing part :4 heat-sealing knives +1 cold-pressing knives

Glue spray system 8 kg TANK

Pneumatic slitting knife

Main cutter

Our Company

Customer Feedback

FAQ

My Contact

Sales Manager:Chris

Whatsapp/Wechat/Phone:+86 13223018559

Похожие товары

Automatic high frequency welding machine for pvc book cover

US $10000-$15000

Высокопроизводительная машина для производства пластиковых пакетов

US $350000-$1000000

Машина для производства мини-сумок на молнии

US $15000-$18600