Низкая цена SKH-612H деревообрабатывающий фрезерный станок с ЧПУ сверлильный для

- Категория: >>>

- Поставщик: Guangdong,Shunde,Changsheng,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.70 $* | 0.84 $* |

| Aug-18-2025 | 0.83 $* | 0.17 $* |

| Jul-18-2025 | 0.52 $* | 0.9 $* |

| Jun-18-2025 | 0.10 $* | 0.26 $* |

| May-18-2025 | 0.22 $* | 0.82 $* |

| Apr-18-2025 | 0.54 $* | 0.13 $* |

| Mar-18-2025 | 0.8 $* | 0.50 $* |

| Feb-18-2025 | 0.27 $* | 0.85 $* |

| Jan-18-2025 | 0.12 $* | 0.20 $* |

Характеристики

Products Description

products details

21 inch color screen control display

Using 21-inch color screen to control the display,

The single-arm suspension is easy to operate and saves floor space.

The operation is safe and reliable, the interface is simple and friendly,

With complete operation tips and troubleshooting guidelines.

The single-arm suspension is easy to operate and saves floor space.

The operation is safe and reliable, the interface is simple and friendly,

With complete operation tips and troubleshooting guidelines.

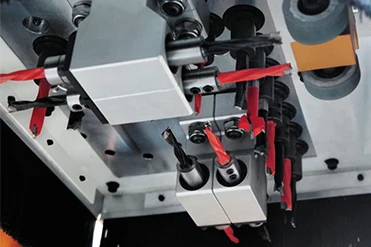

Precision drilling box

Using HUAHUA independently developed CNC drilling box, Manufacturing in accordance with international standards,After three-coordinate detection, the accuracy is guaranteed.

Double clamping and feeding

The double-clamping mechanism is adopted, and the board feeding and positioning are automatically controlled according to the computer drilling program to improve the drilling accuracy.Effectively prevent the edge banding tape from being scratched.

Taiwan's Syntec servo motor

1.Servo control clamp

2.Fast and precise positioning

3.The clamp moving speed can reach up to 130m/min

2.Fast and precise positioning

3.The clamp moving speed can reach up to 130m/min

Flexible discharge

Match with automatic lifting unloading table A variety of unloading options to facilitate automatic connection

Taiwan HIWIN Ball Screw Drive

Using ball screw drive, the screw drive error is within 0.05-0.1MM, the cumulative error is within ±0.2MM, and the service life of the whole machine is improved.

Roller assist transfer table

Prevent sheet scratches

Automatic oil injection system

Cylinder-type oil injection system, all rails use independent cylinders to supply oil, ensuring that all rails are evenly oiled every time.

Control system | 21" PC with Syntec control system with auto loading unloading | ||

Processing Size Range: | Min. Width of work-piece | 50mm | |

Max. Width of work-piece | 1200mm | ||

Max. Length of work-piece | 5000mm | ||

Min. Length of work-piece | 250mm | ||

Max. Thickness of work-piece | 48mm | ||

Min. Thickness of work-piece | 10mm | ||

Position Speed: | X axis: | 5410mm 130m/min | |

Y axis: | 1700mm 80m/min | ||

Z axis: | 140mm 30m/min | ||

U axis | 5410mm 130m/min | ||

V axis | 1395mm 80m/min | ||

Waxis | 110mm 30m/min | ||

A axis: | 1235mm 30m/min | ||

Y 2 axis | |||

Z 2 axis | |||

TOP Drilling unit: | Vertical spindles | 12pcs | |

Horizontal Spindle | 8pcs | ||

Drilling box motor speed | 2800rmp | ||

Router Motor power | 3.5kw speed18000rpm | ||

Bottom Drilling unit: | Vertical spindles | 9 | |

Horizontal Spindle | 0 | ||

Drilling box motor speed | 2800rmp | ||

Router Motor power | 3.5kw speed 18000rpm | ||

Other Data: | Working table height | 960mm | |

Total Power | 19.2kw | ||

Weight | 3500kg | ||

Overall size | 6480*2840*2200mm | ||

Packing&Delivery

Company Profile

Guangdong Shunde Changsheng Machinery Manufacturing Co., Ltd. is founded in 2003, located in Lunjiao Shunde Foshan Guangdong,where is the biggest woodworking machine industry area in south of China. we have 400+ employees including 50+ research staffs, 45000 m2 workshop, can produce 500 sets machines per month.

Our brand name is HUAHUA, has been focusing on the innovation and research of the computer beam saw, cnc drilling machine, edge banding machine and cnc router machine as well as on the machines assembly and software integration, offering a solution to full range of CNC furniture equipment and automatic production line. With good innovation on technology, good management on the production and high quality in service, HUAHUA has been supplying its machines in more than 50 countries. In the future, HUAHUA will keep focusing on research, development, and manufacturing panel furniture machines, welcome more friends to know us and become partners to create a bright future with each other.

Our brand name is HUAHUA, has been focusing on the innovation and research of the computer beam saw, cnc drilling machine, edge banding machine and cnc router machine as well as on the machines assembly and software integration, offering a solution to full range of CNC furniture equipment and automatic production line. With good innovation on technology, good management on the production and high quality in service, HUAHUA has been supplying its machines in more than 50 countries. In the future, HUAHUA will keep focusing on research, development, and manufacturing panel furniture machines, welcome more friends to know us and become partners to create a bright future with each other.

CNC router machine workshop

Edge banding machine workshop

Computer beam saw machine workshop

CNC boring machine workshop

Exhibition

Our Customer

Customer Feedback

Certifications

FAQ

Q1. Are your trading company or factory?

A1. We are factory with more than 45000m2 workshop located in Longwei Road, Xichong Industrial Park, Lunjiao Town, Shunde Dist., Foshan, Guangdong, China.

Q2. What machine can you supply?

A2. Our main machines are computer beam saw, edge banding machine, cnc drilling machine, cnc router machine etc.widely used for panel furniture production.

Q3. What is the payment term?

Q3. T/T 30% in advance and balance before shipment, LC or by negotiation.

Q4. What is the delivery time?

A4. Normal 380V voltage is 15-30 days, other voltage is 30-45days.

Q5. What is the guarantee?

A5. 12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine, you will get spare part for free. Out of 12 months, you will get spare parts at cost price.You will also get technical support and service all the lifetime.

Q6. Can you support the pre-sales service before confirm the order?

A6. Yes ,you will get experienced pre-sales engineer to support, not only including machine and auxiliary selection but also electrical ,air, machine layout in factory ,etc.

Q7. What is the after sales services?

A7. you will be able to get free training advice towards our machine in our factory.

You will also get free suggestion and consultation, technical support and service by online tools.

We can also send our engineer to your factory, but need you take charge of all travelling cost and labour cost

A1. We are factory with more than 45000m2 workshop located in Longwei Road, Xichong Industrial Park, Lunjiao Town, Shunde Dist., Foshan, Guangdong, China.

Q2. What machine can you supply?

A2. Our main machines are computer beam saw, edge banding machine, cnc drilling machine, cnc router machine etc.widely used for panel furniture production.

Q3. What is the payment term?

Q3. T/T 30% in advance and balance before shipment, LC or by negotiation.

Q4. What is the delivery time?

A4. Normal 380V voltage is 15-30 days, other voltage is 30-45days.

Q5. What is the guarantee?

A5. 12 months for the whole machine. Within 12 months under normal use and maintenance, if something is wrong with the machine, you will get spare part for free. Out of 12 months, you will get spare parts at cost price.You will also get technical support and service all the lifetime.

Q6. Can you support the pre-sales service before confirm the order?

A6. Yes ,you will get experienced pre-sales engineer to support, not only including machine and auxiliary selection but also electrical ,air, machine layout in factory ,etc.

Q7. What is the after sales services?

A7. you will be able to get free training advice towards our machine in our factory.

You will also get free suggestion and consultation, technical support and service by online tools.

We can also send our engineer to your factory, but need you take charge of all travelling cost and labour cost

Похожие товары

Price Of Drill Machine Horizontal Wood Hole Drilling Machine

US $1420-$1555

single double head vertical door hinge hole drilling wood boring machine

US $499.00-$799.00