4x8 WPC пенопластовый лист для цифровой

- Категория: Golf >>>

- Поставщик: Zhanjiang,Boardway,Building,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.39 $* | 0.25 $* |

| Aug-20-2025 | 0.46 $* | 0.68 $* |

| Jul-20-2025 | 0.39 $* | 0.57 $* |

| Jun-20-2025 | 0.98 $* | 0.45 $* |

| May-20-2025 | 0.93 $* | 0.86 $* |

| Apr-20-2025 | 0.97 $* | 0.41 $* |

| Mar-20-2025 | 0.96 $* | 0.40 $* |

| Feb-20-2025 | 0.54 $* | 0.47 $* |

| Jan-20-2025 | 0.48 $* | 0.80 $* |

Характеристики

Products Description

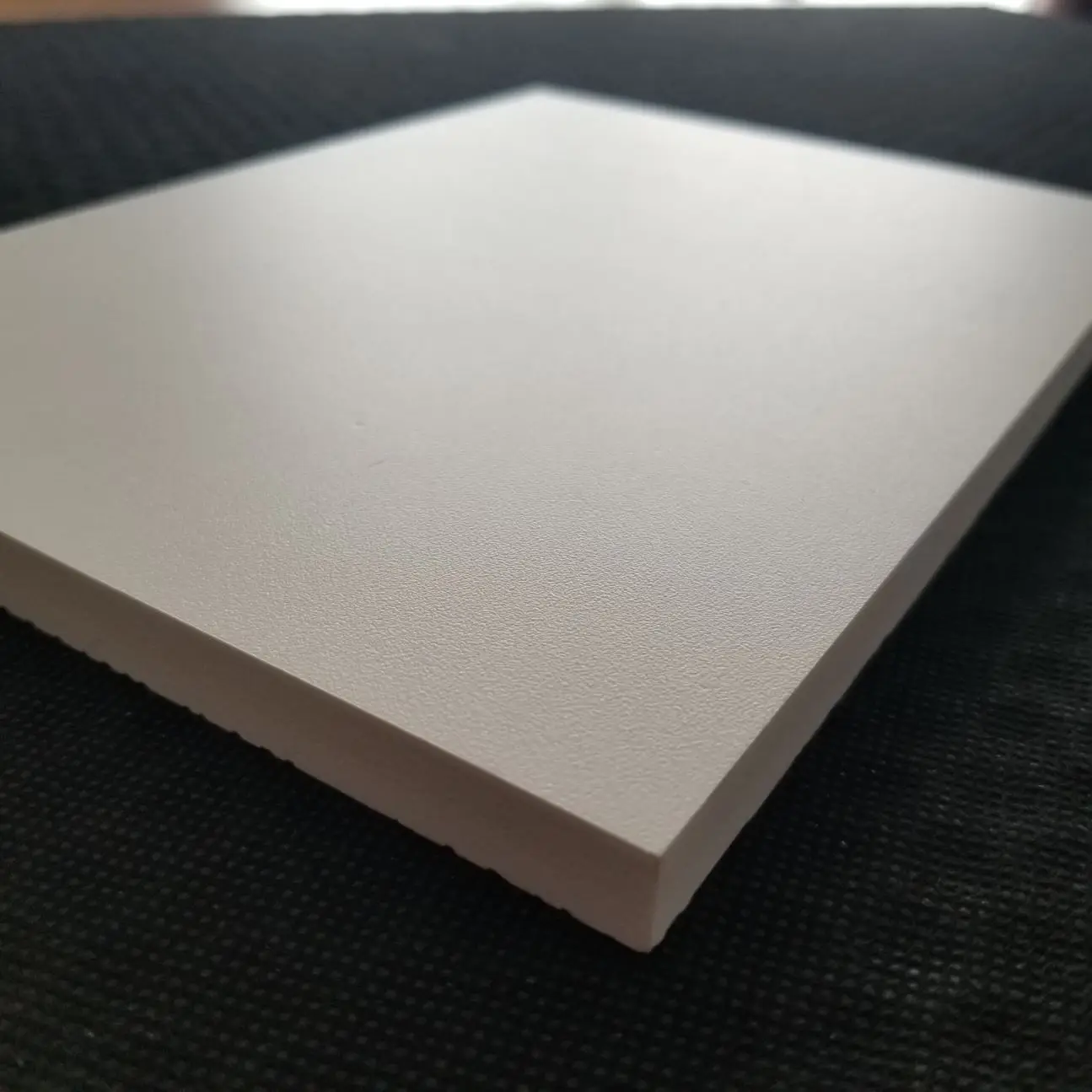

WPC foam board

is made of polyvinyl chloride resin, added with wood powder and special additives and extruded.

It is a waterproof, lightweight, expanded rigid plastic board that can be used in various applications, including kitchen and bathroom cabinets, interior decoration, booths, advertising signs and displays, prototypes, etc.

Due to its high workability, WPC foam board can be easily processed by sawing, cnc-cutting, printing, sanding, routing, painting, laminating, etc.

What is the difference between WPC foam board and PVC foam board?

WPC foam board has all the advantages of PVC foam board. It is lightweight, waterproof, mildew-proof, and moth-proof, which is very suitable for use in humid environments, such as, used as kitchen and bathroom cabinets. It is the best alternative material for traditional solid wood panel, plywood, particle board.

Different from PVC foam board, WPC foam board contains a small amount of natural wood powder, thereby strengthening the nail holding force of the board. The color of WPC foam board we see is the color of natural wood powder in its formula. WPC foam board is environmentally friendly, non-toxic, the used materials can be recycled and reused.

Different from PVC foam board, WPC foam board contains a small amount of natural wood powder, thereby strengthening the nail holding force of the board. The color of WPC foam board we see is the color of natural wood powder in its formula. WPC foam board is environmentally friendly, non-toxic, the used materials can be recycled and reused.

Details Images

WPC Celuka Foam Board

Best-selling

WPC Co-extruded Foam Board

Wood-colored surface

WPC Co-extruded Foam Board

White surface

Production of WPC foam board

Boardway has five WPC foam board production lines, which can produce two types of WPC boards: WPC celuka board and WPC co-extruded board.

WPC foam board stocks

Boardway warehouse has a large number of WPC foam boards in stock, which can meet urgent order requirements. Welcome to contact us to purchase.

Sanded surface

According to market demand, customers want more surface choices. Many of our customers use WPC foam board instead of MDF, and customers usually laminate melamine onto MDF. Laminated thin skins, such as melamine or pvc film, require a very fine surface on the substrate. In order to meet this requirement, Boardway provides WPC foam board with sanded surface.

Some of our customers use wood-grain WPC foam panels directly as cabinets. The surface of the WPC foam board does not need to be veneered or painted.

Boardway wood-grain WPC foam board has good scratch resistance and is easy to clean. It is also the most popular material for kitchen cabinets.

Boardway wood-grain WPC foam board has good scratch resistance and is easy to clean. It is also the most popular material for kitchen cabinets.

Specification

WPC Celuka Foam Board | ||||||||

Length | 2440mm, 3050mm, 3600mm, length can be customized | |||||||

Width | 915mm, 1220mm | |||||||

Thickness | 5-30mm | |||||||

Density | 0.4-0.9g/cm3 | |||||||

Finished Surface | Smooth, wood grain, sanded surface | |||||||

WPC Co-extruded Foam Board | ||||||||

Length | 2440mm, 3050mm, 3600mm, length can be customized | |||||||

Width | 1220mm | |||||||

Thickness | 5-18mm | |||||||

Density | 0.4-0.9g/cm3 | |||||||

Finished Surface | Glossy | |||||||

Quality Control

Quality is above all else.

Boardway has a complete quality control system. In order to ensure zero defect and zero complaints, we monitor and control every link from raw materials to production, to the warehousing and shipment of finished products. The inspection includes the appearance data of the product, including the length, width, thickness, weight, flatness, hardness, surface and cross section. In addition, according to customer requirements and application conditions, we have well-equipped facilities to test the physical and chemical properties of the products, such as the impact strength, aging resistance, flame retardancy, etc.

Application

Processing

Product packaging

Why Choose Us

Похожие товары

ПВХ облицовка стен сайдинг

US $4.00-$6.00

Защитная сетка для желоба

US $15.99-$19.99

Защитный фильтр для листьев водосточных желобов

US $1.20-$1.95