Оборудование для сканирования и сортировки посылок в линию централизованное транспортировочное оборудование

- Категория: Cargo & Storage Equipment >>>

- Поставщик: Senad,Robot(Shanghai)Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.83 $* | 0.26 $* |

| Aug-18-2025 | 0.30 $* | 0.26 $* |

| Jul-18-2025 | 0.91 $* | 0.28 $* |

| Jun-18-2025 | 0.44 $* | 0.61 $* |

| May-18-2025 | 0.43 $* | 0.36 $* |

| Apr-18-2025 | 0.24 $* | 0.95 $* |

| Mar-18-2025 | 0.9 $* | 0.76 $* |

| Feb-18-2025 | 0.50 $* | 0.92 $* |

| Jan-18-2025 | 0.22 $* | 0.55 $* |

Характеристики

Product Description

Parcel in-line singularizing centralized conveying dimensioning weighing scanning and sorting equipement for logistics warehouse

But it's heavy tast and slow.

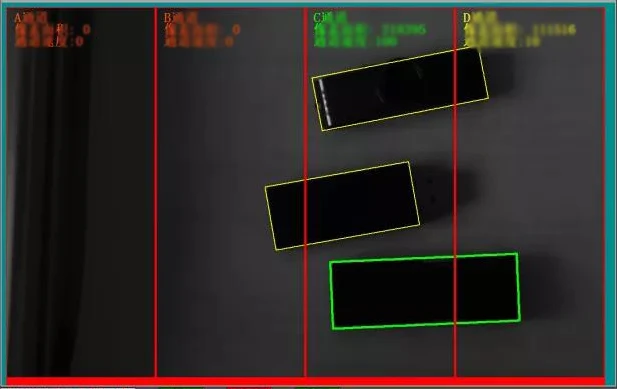

The single parcel separation system is to recognize and position the parcels and deep learing the contourgraph of parcels and then separate them one by one, and convey it to the next centralized converyor in order.

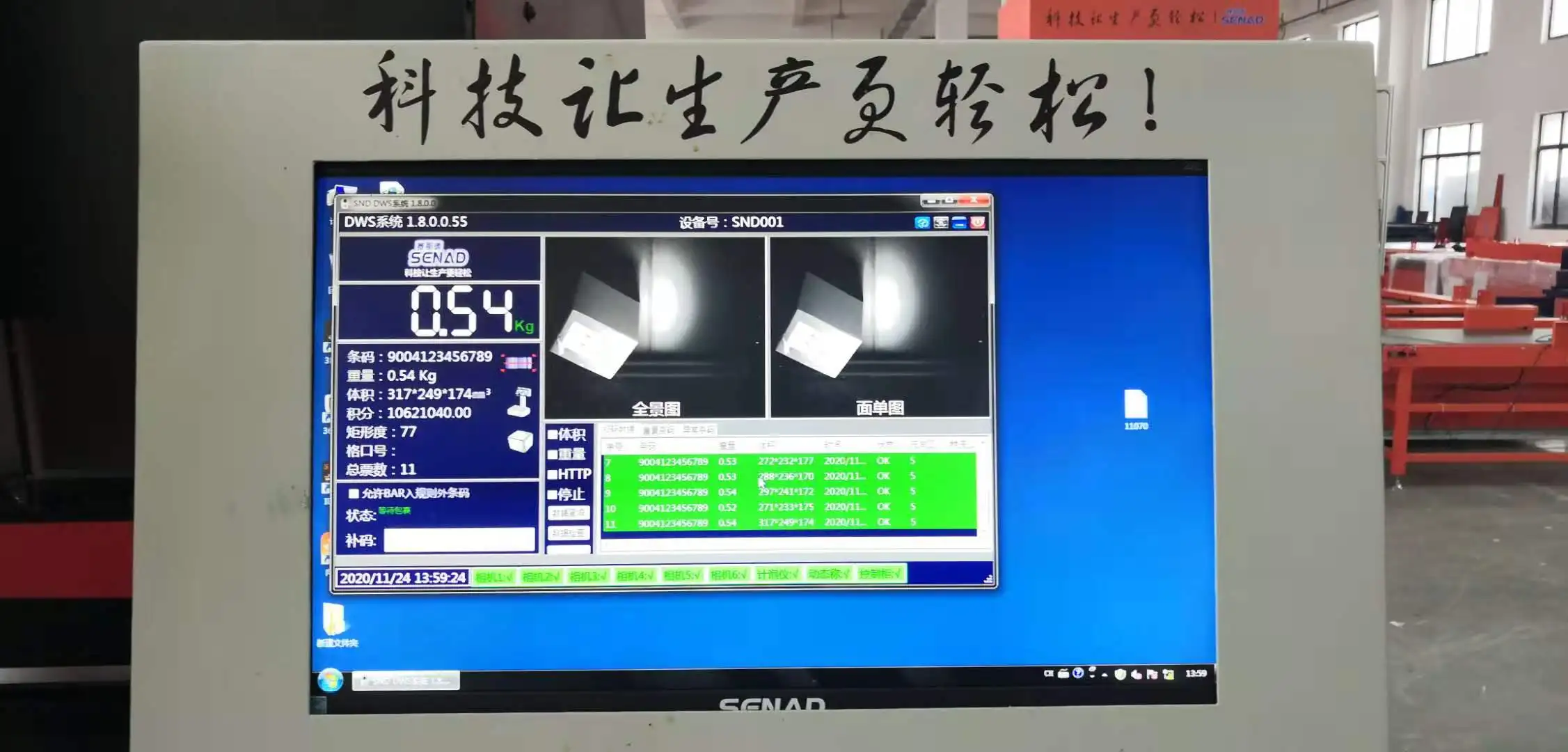

Then the parcels go through the DWS system in a center line stream, the ship information are collected, such as barcodes,weights and L*W*H dimensions, photos, and the data are sent to the WMS in real time.

The WMS software will response to the automation line and instruct the parcels where to go.

It is showed that this single-piece separation system processes nearly 3000-8000 packages per hour, with a separation accuracy of 99.7%.

It is showed that this single-piece separation system processes nearly 3000-8000 packages per hour, with a separation accuracy of 99.7%.

Features

Parcel singulator

Separate packages in left and right directions

Separate packages in straight forward directions

Always convey the frontest package first

Centralize the conveying of separated packages

Effect: Transit a cluttered pile into a single stream line in order.

Parcel sorting line

Collect barcodes, weights and volume dimensions

Sort parcels into different destinations according to barcode rules

Effect: Realize easy parcel information collections and distribution classification

Specification

Parcel singulating stage | ||

Package type | Carton, soft package,sacks,Envelops,etc. | |

Mini package height | 20mm | |

Max package height | 800mm | |

Functions | Package pulling, posioning, and singulatinig | |

Singulating rate | >99.5% | |

Power | <25kw | |

Belt modular | 24 rows, 32 rows, 48rows... | |

Configurations | Smart camera, 3D camera, industrial computer, PLC, Servo motor, Belt conveyor modular | |

Temperature | Work at 0 ~ 50℃; stor at -30 ~ 70℃ | |

Humidity | 20%~80%RH | |

Light | Avoid natural light, use it indoors or with shading shade | |

Parcel sortation stage | ||

Working efficiency | 2600-3600pcs/h | |

Contained parts | Head part: parcel speed-up conveyor | |

Core part 1: In-motion Dimension Weigh Scan conveyor | ||

Core part 2: Belt conveyor and sorting conveyor modular | ||

End part: Other parts if needed | ||

Barcode reading direction | Top scan (Side scan can be added) | |

barcode reading rate | 99.99% (Barcode condition good enough) | |

Belt Speed | 90mm/min | |

Belt width | 800mm/1000mm/1200mm | |

Minimum size suggested | 150*150*20mm | |

Maximum size suggested | 1200*1200*800mm | |

Dimension accuracy | ±10mm for standard packages | |

Weight range | 0.04-60kg | |

Weighing accuracy | ±20g | |

Dynamic weighing conveyor | One (Two dynamic weighing conveyors is made for large packages) | |

Sorting destination quantity | Customization | |

Power | different based on the quantity of sorters | |

Software | Camera system, DWS system, PLC control program | |

Operation system | Windows 7/10 32/64bits | |

Environment temperature | 0-50℃ | |

Environment Humidity | 20-80%RH No condensation | |

Configurations | Smart cameras,3D cameras,Industrial computer, dynamic weighing components,PLC, servo motor, modular split belt conveyors | |

Readable barcodes | EAN 8,EAN 13,Code 128,Code 39,Code 93,interleaved 2 of 5,CodaBar,QR code,Data Matrik,PDF 417,UPU(customized) | |

Overall solutions | Parcel positioning, controlling, separating, centralized queuing, parcel conveying, barcode sccanning, weighing, (dimensioning), parcel photoing, data uploading, sorting | |

Product Shows

Company Profile

Senad is a high-tech enterprise concentrated on research & development and production of high-end warehouse automation equipments.

There are not only standard equipments but also customizable ones to realize different functions,such as high speed bulk packages barcode scanning, static and dynamic weighing,volume dimensions measuring,conveying and sorting,as well as the DWS integrated line system and also face recognition system,feeding systems,automatic conveying equipment,and follow-up robot,transportation robot,etc.The information collected can be stored, downloaded and shared to the users' management system.

The equipments take machine vision deep learning algorithms and robotic motion control as the core,and image processing algorithms,artificial intelligence,pattern recognition,video analysis algorithms, ARM|FPGA|DSP embedded software and hardware development,industrial machine vision positioning,visual tracking,visual inspection,multi-sensor information fusion and other technical means,to achieve the goal of "replacing manual labor with robot".

These equipments are designed to sent companies free from the problems of "Labor shortage,Labor expensiveness and Labor difficulty" and disputes and losts because of manual typo-error, and can achieve a highly rised working efficiency.

Technology makes production easier.

We pursuit a win-win situation. Our mission is to bring our partners easier work and higher efficiency.We will constantly contribute in upgrading and developing new technologies for practical application and provide high quality equipments and professional consultant services to our partners.

There are not only standard equipments but also customizable ones to realize different functions,such as high speed bulk packages barcode scanning, static and dynamic weighing,volume dimensions measuring,conveying and sorting,as well as the DWS integrated line system and also face recognition system,feeding systems,automatic conveying equipment,and follow-up robot,transportation robot,etc.The information collected can be stored, downloaded and shared to the users' management system.

The equipments take machine vision deep learning algorithms and robotic motion control as the core,and image processing algorithms,artificial intelligence,pattern recognition,video analysis algorithms, ARM|FPGA|DSP embedded software and hardware development,industrial machine vision positioning,visual tracking,visual inspection,multi-sensor information fusion and other technical means,to achieve the goal of "replacing manual labor with robot".

These equipments are designed to sent companies free from the problems of "Labor shortage,Labor expensiveness and Labor difficulty" and disputes and losts because of manual typo-error, and can achieve a highly rised working efficiency.

Technology makes production easier.

We pursuit a win-win situation. Our mission is to bring our partners easier work and higher efficiency.We will constantly contribute in upgrading and developing new technologies for practical application and provide high quality equipments and professional consultant services to our partners.

Our Factory

PATENTS

HONOURS

COOPERATION CASES

PARTNER

Recommend Products

Contact Us

wHY CHOOSE US

◆ High-tech manufacturer with research and design capacity

◆ Concentrated on DWS equipments and sorting warehousing system overall solution

◆ Related software and system are with patents

◆ Stable and mature suppling system

◆ Young active sales and engineers for instant services

◆ Upgrading on mechanism according to ergonomics and easy maintenance

◆ High-tech manufacturer with research and design capacity

◆ Concentrated on DWS equipments and sorting warehousing system overall solution

◆ Related software and system are with patents

◆ Stable and mature suppling system

◆ Young active sales and engineers for instant services

◆ Upgrading on mechanism according to ergonomics and easy maintenance

After services:

1. On-site installation & commissioning.

2. Respond within 24 hours

3. One year free repair service

4. Remote diagnosis & online guidance

5. System upgrading

2. Respond within 24 hours

3. One year free repair service

4. Remote diagnosis & online guidance

5. System upgrading

Contact us:

Manufacturer: Senad Robot (Shanghai) Co., Ltd.

ATTN: May He

MP: +86-180 1627 5415 (wechat and whatsapp)

TEL: +86-21-5991 9555

FAX: +86-21-5992 0633

EMAIL: may@senad.cn (Skype)

WEB: www.senadrobot.com

ADD.: No. 599,Huiwang East Road, Jiading, Shanghai China

ATTN: May He

MP: +86-180 1627 5415 (wechat and whatsapp)

TEL: +86-21-5991 9555

FAX: +86-21-5992 0633

EMAIL: may@senad.cn (Skype)

WEB: www.senadrobot.com

ADD.: No. 599,Huiwang East Road, Jiading, Shanghai China