Ферментативный реактор с фиксированной кроватью/катализационный

- Категория: Reactors >>>

- Поставщик: Weihai,Chem-Equip,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 3570.31 $* | 3749.28 $* |

| Aug-16-2025 | 3540.95 $* | 3717.38 $* |

| Jul-16-2025 | 2970.85 $* | 3119.45 $* |

| Jun-16-2025 | 3480.72 $* | 3654.18 $* |

| May-16-2025 | 3030.33 $* | 3182.69 $* |

| Apr-16-2025 | 3420.9 $* | 3591.25 $* |

| Mar-16-2025 | 3390.60 $* | 3560.40 $* |

| Feb-16-2025 | 3360.23 $* | 3528.57 $* |

| Jan-16-2025 | 3330.37 $* | 3497.82 $* |

Характеристики

Product Description

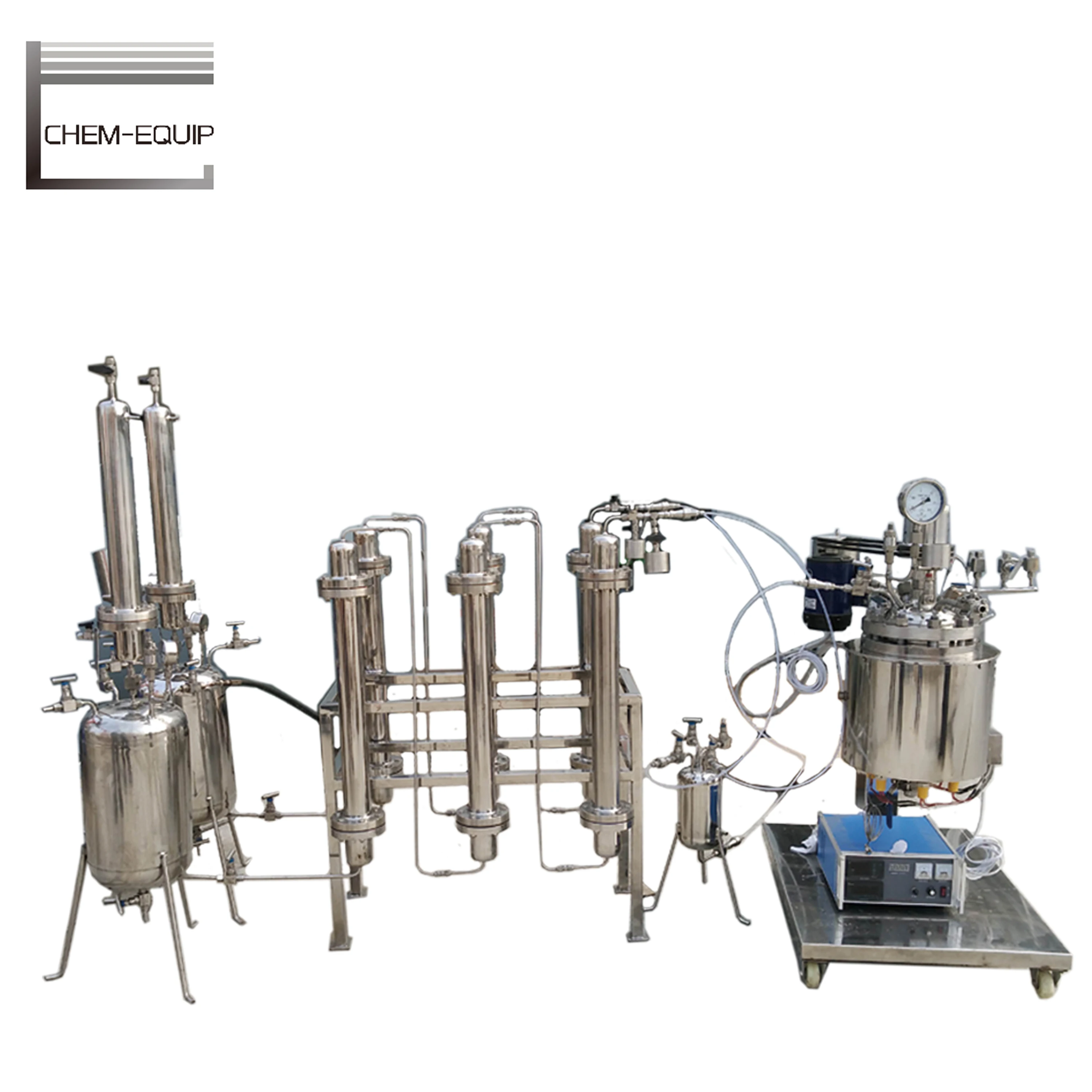

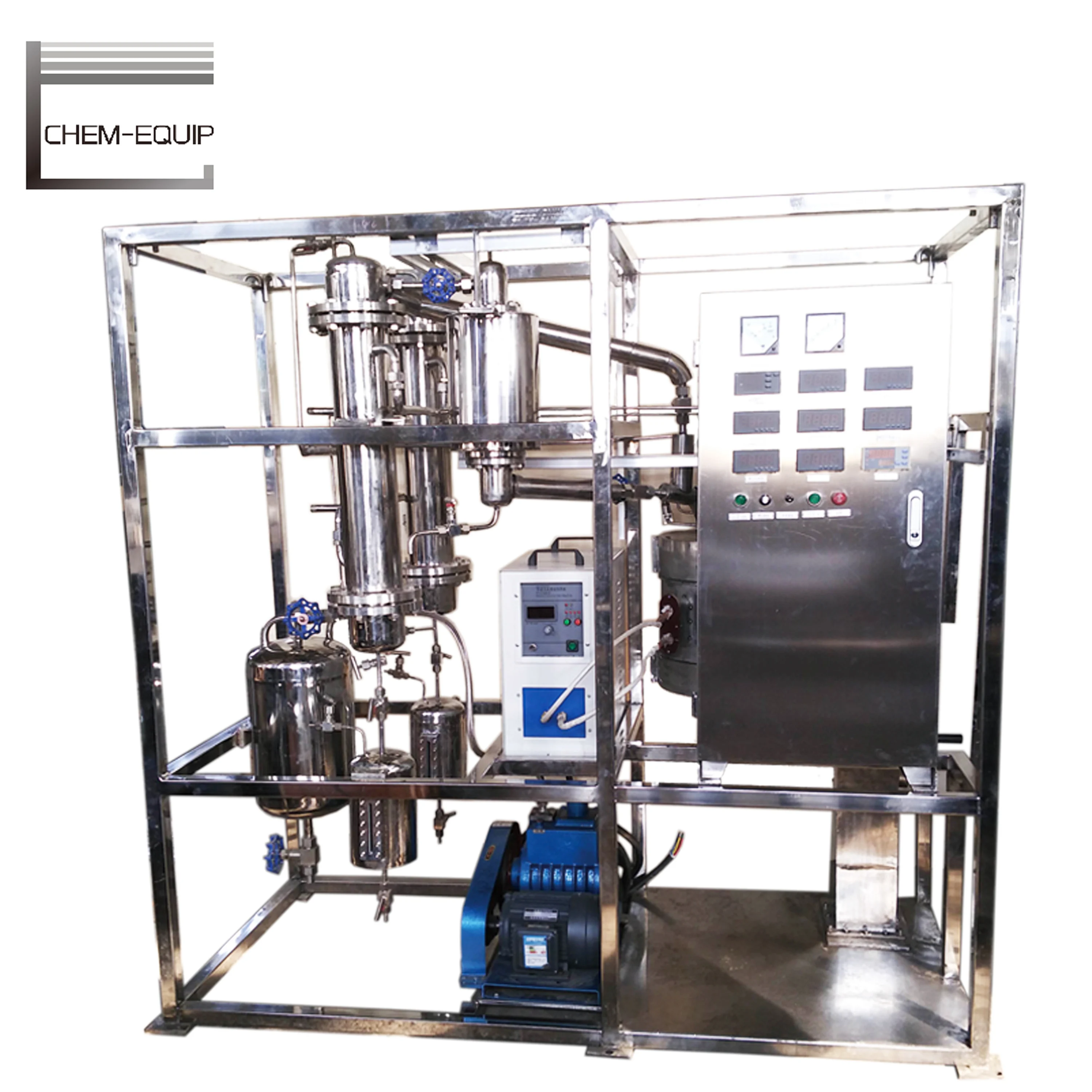

A Tubular Reactor that is paced with solid catalyst particles, gas and liquid goes through packed bed structure, can make whole process completely and constantly.

Tubular reactor is always used in a continuous flow mode with reactant flowing in. The catalytic is packed in the Raschig Rings or Layers mounted inside reactor.

Tubular reactor is also called Pipe reactor, Packed bed reactor, Fixed Bed Reactor, Catalyst Bed Reactor, etc.

Tubular reactor is always used in a continuous flow mode with reactant flowing in. The catalytic is packed in the Raschig Rings or Layers mounted inside reactor.

Tubular reactor is also called Pipe reactor, Packed bed reactor, Fixed Bed Reactor, Catalyst Bed Reactor, etc.

.

Chem-Equip reactor is widely used in a big range, like Medical Industrial, Food Industrial, Chemical Industrial, Raw Material Industrial, Petroleum Industrial, Energy Industrial, New Material and Polymolecular Industrial.

Specification

Specifications and Technical Parameters | ||||||||

Working pressure (MPa) | Negative pressure -0.1~40 | |||||||

Working temperature (℃) | -196~600 | |||||||

Heating type | Electric heating, water recycling, thermal oil, steam, far infrared heating, high frequency heating. Tubular reactor can have a single wall and be heated with an external furnace or they can be jacketed for heating or cooling with a circulating heat transfer fluid. | |||||||

Charging type | As per process flow chat. | |||||||

Main material | Contacting material inside kettle mainly use SUS304, SUS316LL, SUS321, also can be produced by titanium(TA2), nickel, zirconium, hastelloy, etc, or lined with PTFE, PPL, PFA and Ni (Ni6) according to different requirements of reaction media. | |||||||

Controller Device | Equipped with automatic or programmed PID or PLC to achieve: Temperature display and control, accuracy ± 1 ℃ (or ±0.1 ℃); Mixing Speed display and control; Pressure display and control; Level display and control; Flow display and control; Valve open/close control, etc. | |||||||

Other Accessories | The structure of Tubular Reactor can be made completely as per customer’s request. Can assemble various instruments as per request. | |||||||

1. High conversion per unit mass of catalyst, make a complete and constant reaction, suitable for Solid Catalyzed and Gas Phase reaction.

2. Good mixing under low operating cost, catalysts can be continuously regenerated with the use of an auxiliary loop.

3. Good temperature uniformity, all reactants in various phases can flow inside reactor kettle evenly, and be heated evenly.

Packed Bed: It’s a hollow tube, pipe, or other vessel that is filled with a packing material. The packing can be randomly filled with small objects like Raschig Rings or else it can be a specifically designed structured packing. Packed beds may also contain catalyst particles or adsorbents such as zeolite pellets, granular activated carbon, etc.

The purpose of a packed bed is typically to improve contact between two phases in a chemical or similar process. Packed beds can be used in a chemical reactor, a distillation process, or a scrubber, but packed beds have also been used to store heat in chemical plants. In this case, hot gases are allowed to escape through a vessel that is packed with a refractory material until the packing is hot. Air or other cool gas is then fed back to the plant through the hot bed, thereby pre-heating the air or gas feed.

The purpose of a packed bed is typically to improve contact between two phases in a chemical or similar process. Packed beds can be used in a chemical reactor, a distillation process, or a scrubber, but packed beds have also been used to store heat in chemical plants. In this case, hot gases are allowed to escape through a vessel that is packed with a refractory material until the packing is hot. Air or other cool gas is then fed back to the plant through the hot bed, thereby pre-heating the air or gas feed.

For different chemical process, the reactor can be designed into various structures, we have experience in types of reactor system

.

Company Profile

With 10 years experience in chemical industry,

Weihai Chem-Equip Machinery Co., Ltd is a professional supplier in various chemical equipment, we help customer design, develop and fabricate suitable production lines, from initial chemical process design, to workshop building and long term maintaince.

We have own factories in Weihai and Laizhou area, product covers Reactor, Pressure Vessel, Mixer, Kneader, Sand Miller, Filter, Dryer etc, almost cover all chemical industry.

With our Chemical Process Designer, ASME AI (Authorized Inspector), American CWI (Certified Welding Inspector), we dedicate in a Turn-Key solution for customers who wants to build up new factory or expand new production lines, in an efficient and safety way.

We have own factories in Weihai and Laizhou area, product covers Reactor, Pressure Vessel, Mixer, Kneader, Sand Miller, Filter, Dryer etc, almost cover all chemical industry.

With our Chemical Process Designer, ASME AI (Authorized Inspector), American CWI (Certified Welding Inspector), we dedicate in a Turn-Key solution for customers who wants to build up new factory or expand new production lines, in an efficient and safety way.

FAQ

Pre-Sale Stage

Provide Chemical Process , Project Drawing and Suitable Equipment Model according to customer's request, for accurate design and quote, please kindly advise below:

Whole time report for manufacture status;

Inspection video for quality checking;

Full set Engineering Documents, include User Manual, General Drawing, Electric Circuit Drawing, All Related Test Report, Approval Certificate.

Life long service for all equipment;

Free spare parts in warranty period;

Discount price for all spare parts after warranty period;

Technical consulting is always for free.

Arrange engineer to assist customer in equipment assembly and installation;

Training workers to use machine properly.