Лидер продаж машина для производства соленых печенья

- Категория: Biscuit making machine >>>

- Поставщик: Skywin,Foodstuff,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.31 $* | 0.71 $* |

| Aug-19-2025 | 0.70 $* | 0.25 $* |

| Jul-19-2025 | 0.14 $* | 0.76 $* |

| Jun-19-2025 | 0.25 $* | 0.49 $* |

| May-19-2025 | 0.49 $* | 0.61 $* |

| Apr-19-2025 | 0.85 $* | 0.45 $* |

| Mar-19-2025 | 0.24 $* | 0.1 $* |

| Feb-19-2025 | 0.59 $* | 0.38 $* |

| Jan-19-2025 | 0.40 $* | 0.10 $* |

Характеристики

Hot Sale Salty Pretzel Biscuit Production Line

Pretzel Biscuit Making Machine Pretzel Biscuit Machine

Machine component:

1. Chinese famous brand motor & gearbox

2. Main bearing use Chinese brand, other small use NSK

3. AirTAC Pneumatic cylinder for belt tension and deflecting adjustment

4. PU and Cotton belt

5. 304 Stainless steel cover, thickness 1.5mm

6. SIEMENS transducer electric and PLC touch screen control.

7. Guarantee for 1 year along with recommended spare parts for 1 year.

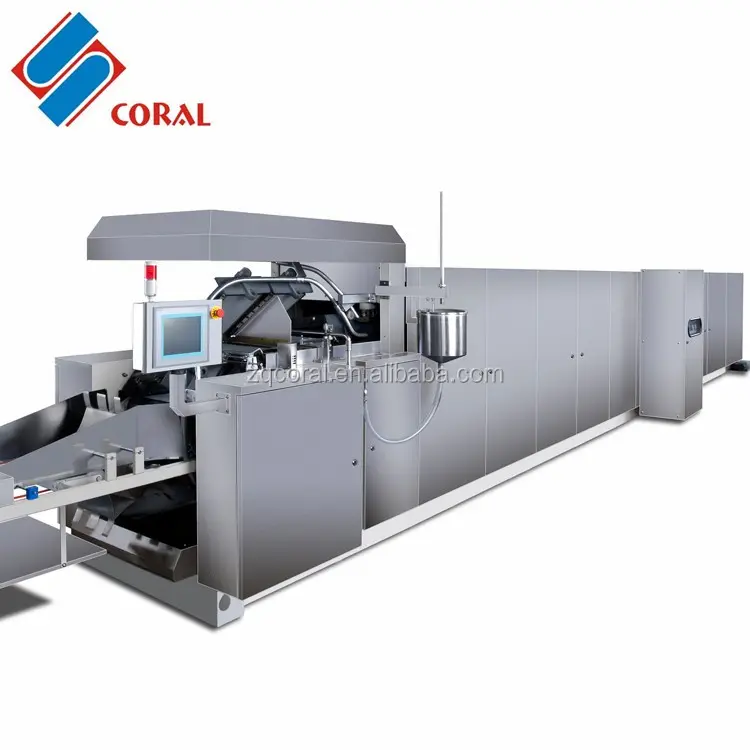

A whole line consist of:

1.Horizontal dough mixer

2.Automatic dough tipper and feeding system

3.Pretzel Extruder with Cutter

4.Pretzel Cooker

5.Salt and Sugar Sprinkle

6.Tunnel oven: Diesel, electric, indirect gas fried or hybrid gas oven for option

7.Turning machine 180° or 90° design as per the plant length

8.Cooling conveyor and stacking machine (start wheel stacker or penny stacker)

Horizontal Dough Mixer

1. Capacity: 150-750kg

2. Multi mixing speed: low speed 25rpm/min and high speed to 50rpm/min

3. Mixing blade is 304 Stainless steel

4. Bowl covered by 304 Stainless steel

5. Machine Cover made by 304 Stainless steel

6. Tipping by Hydraulic pressure

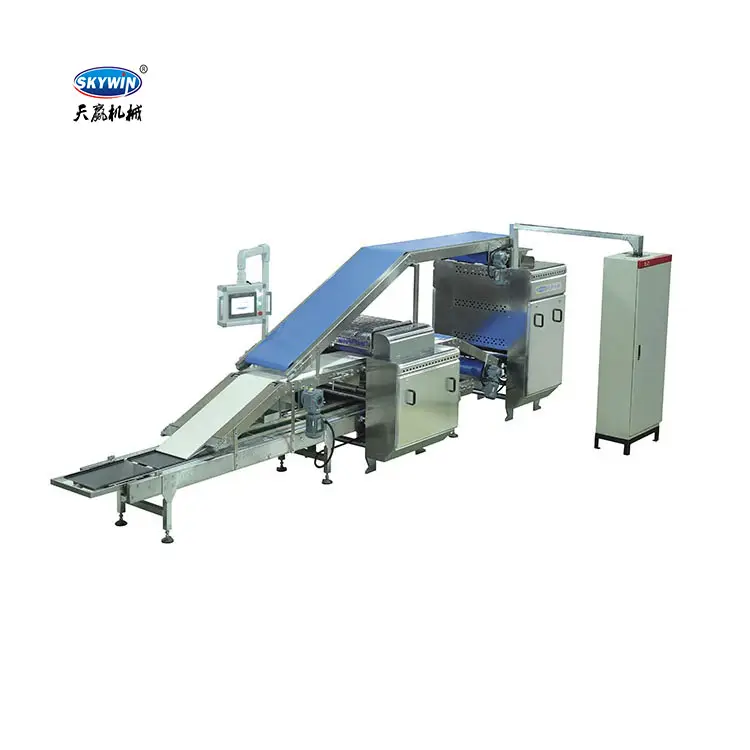

Automatic dough tipper and feeding system

Function: Hydraulic pressure tilting dough, Cut dough into small pieces and send them to the feeding machine(rotary moulder). Tilting time 20-25 seconds around

Pretzel Extruder with Cutter

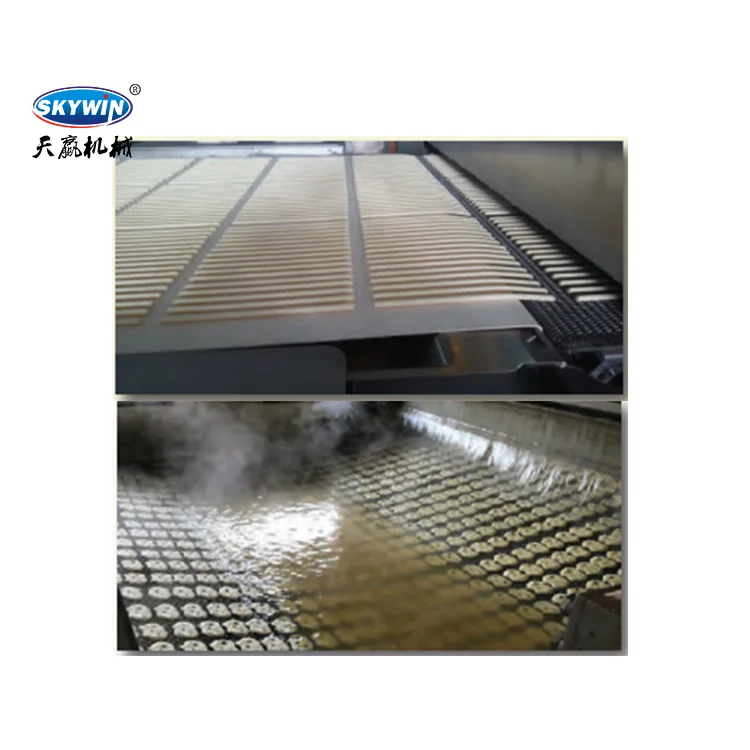

Pretzel Cooker

Soda water heating tank with 90degree temperature

Enter Stove Machine

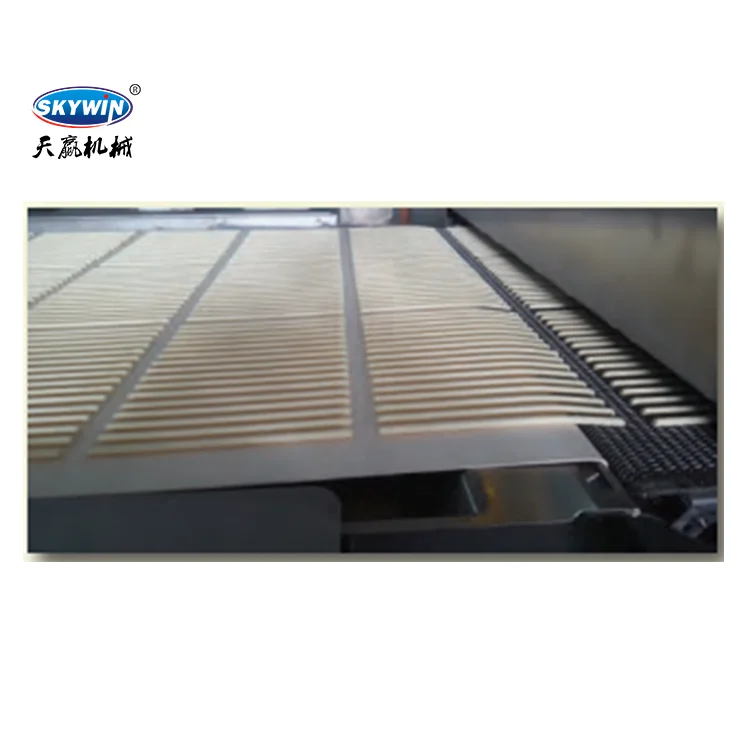

1. Oven Belt Driven System

2. With Belt tracking device

3. Roll diameter: 900mm

Tunnel Oven

1. The length of Oven body is customized

2. Weishaupt brand Gas burner

3. 3 set pneumatic tracking installed on enter oven, exit oven and oven bottom

4. Pneumatic automatic tracking and adjust belt and tension and Panasonic Sensors .

5. Oven cover by 304 Stainless steel, 1.5mm thickness

Out stove & Peeling Machine: 180°Curve Machine

1. As transition device from oven

2. Stainless steel mesh belt

Cooling conveyor

1. total length according to layout 3. Independent frequency inverter control

2. Food grade PU belt width 650mm

Stacker

1. Star wheels and penny stacking 3. Independent frequency inverter control and adjust

2. Food grade PU belt

Packing table

1. PU belt total length according to layout

2. Independent frequency inverter control and adjust

♥Looking forward to your inquiry♥

Name: Windy

Mobile/Whatsapp: +86 152 1784 4285

| Step | Process |

| Step 1 | Mechanical surface coated with preservative solution (to protect stainless steel). |

| Step 2 | The plastic cushion packing machine (prevent bump). |

| Step 3 | Plastic film packaging (to prevent ventilation). |

| Step 4 | Wooden case / frame packaging (easy to transport). |

| Step 5 | Tie the bandage outside of the wooden case (reinforcement overall). |

♥ Looking forward to your inquiry ♥

Name: Windy

Mobile/Whatsapp: +86 152 1784 4285