Практичная и доступная небольшая машина для изготовления брикетов с древесным

- Категория: Briquette Machines >>>

- Поставщик: Henan,Kunmin,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.29 $* | 0.9 $* |

| Aug-16-2025 | 0.11 $* | 0.83 $* |

| Jul-16-2025 | 0.55 $* | 0.61 $* |

| Jun-16-2025 | 0.76 $* | 0.12 $* |

| May-16-2025 | 0.80 $* | 0.48 $* |

| Apr-16-2025 | 0.88 $* | 0.98 $* |

| Mar-16-2025 | 0.54 $* | 0.90 $* |

| Feb-16-2025 | 0.94 $* | 0.65 $* |

| Jan-16-2025 | 0.63 $* | 0.77 $* |

Характеристики

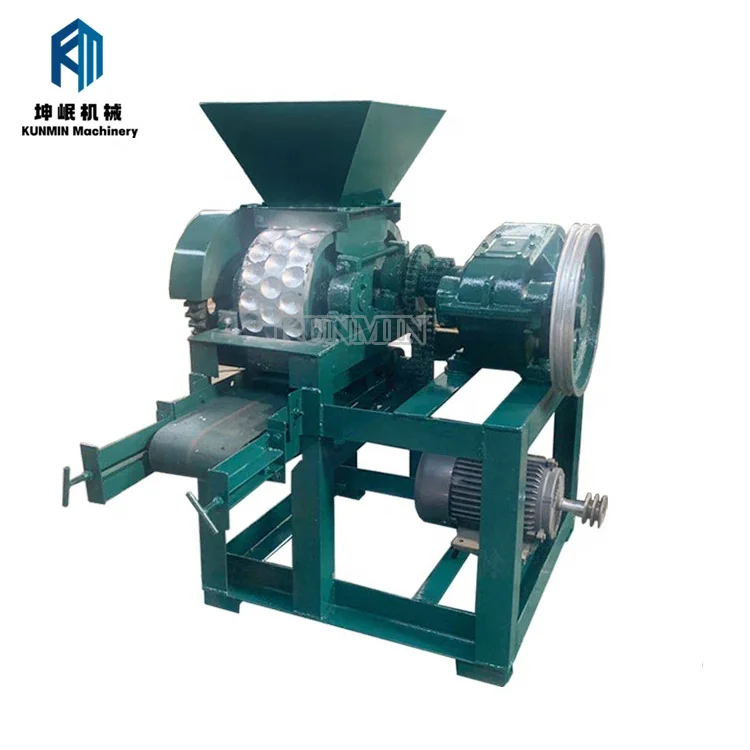

Practical And Affordable Small Scale Charcoal Stick Briquette Machine Making

Briquette charcoal is widely used to making coal powder into briquettes for boiler, furnace,

home heating, etc. It is also suitable for other raw materials such as gypsum,fluorspar,charcoal, coke, iron fines, chrome ore and other kinds of powder materials.

Feature of our charcoal briquette machine making:

Our Advantage:

1.The roller is made by hard materials with good wear resistance and long life time.The

service life of wearing parts is up to 4000 hours.

2.The machines electricity coal reduce by 60%.

3.The machine is easy to operate and maintain.

4.The molding materials are energy saving, easy to tansport and higher utilization of waste.

5.The final products are smokeless, non-toxic, none peculiar and environmental protection.

Working principle:

1.This charcoal ball press machine can press charcoal powder, charcoal dust, coal powder,

etc into round ball, oval ball or pillow-shaped charcoal.

2. This series of ball press machine will pass the power on to the two pressure roller

through the reducer. The two sides and roll rotation, in both the rotating roll.

3. Natural materials to enter the ball roll mode, with the roll rotation, material pressure

on a small become larger. When the material to the two rollers rotating line contact point,

the pressure of materials has reached the peak. Tremendous pressure in the role of line, the

materials becomes a finished product from the powder ball.

Our Feature:

1.Production materials type: such as coal powder, charcoal powder, coconut shell charcoal

powder etc.

2.Materials size required before feeding charcoal briquette machine: less than 3mm. If the

size is larger than 3mm, it is necessary to crush them into smaller size for briquetting.

3. Moisture content: less than 15%.

4.Shape of final product:The briquette shape can be round type,pillow shape,oval type,bread

shape and so on, which is widely used for BBQ,barbecue,boiler,heating,metallurgy,chemical,etc.

Specification of our charcoal briquette machine making:

Model | KM-HY-300 | KM-HY-350 | KM-HY-500 | KM-HY-600 |

Briquettes shape | 20*10-60*30 oblate | 25*12-70*50 oblate | 25*12-70*50 oblate | 25*12-70*50 oblate |

Squeeze force of profile wheel | 800kg/ cm | 1000kg/ cm | 2800kg/ cm | 3500kg/ cm |

Type wheel speed | 16r/min | 18r/min | 20r/min | 22r/min |

Equipped with power | 4KW-4 level | 11KW-4 level | 22 level | 37 level |

Reducer | 250 type | 400 type | ZQ500type | ZQ650type |

Capacity | 6 tons/hour | 6-8 tons /hour | 10-12 tons /hour | 12-15 tons /hour |

Weight | 600kg | 1300kg | 2200kg | 4500kg |

Dimensions | 2200*1100*1150mm | 2300*1100*1200mm | 2800*1500*1750mm | 3000*2000*2000mm |

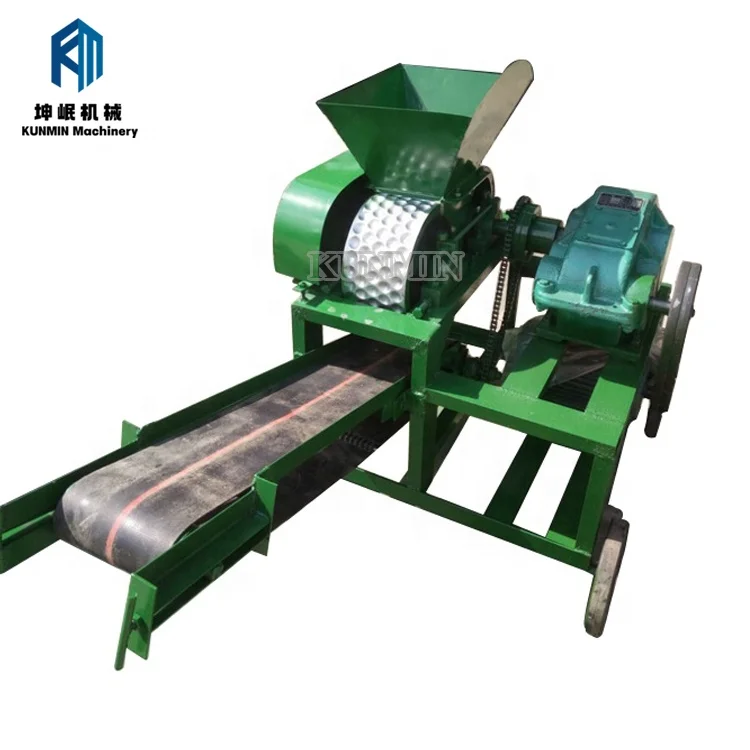

Products show of our charcoal briquette machine making:

Our Brick making machine:

OUR CERTIFICATES

PACKAGE:

Standard export carton or wooden case packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.