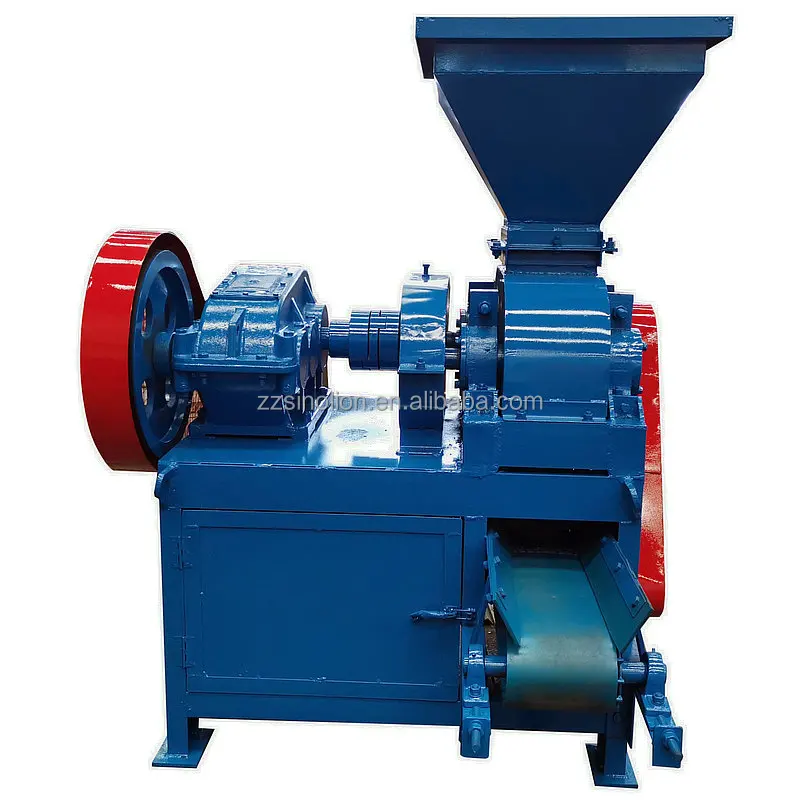

Рулонный пресс угля машина по изготовлению угольных брикетов древесного порошок

- Категория: Briquette Machines >>>

- Поставщик: Zhengzhou,Sinolion,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.54 $* | 0.29 $* |

| Aug-19-2025 | 0.27 $* | 0.2 $* |

| Jul-19-2025 | 0.81 $* | 0.37 $* |

| Jun-19-2025 | 0.29 $* | 0.70 $* |

| May-19-2025 | 0.65 $* | 0.5 $* |

| Apr-19-2025 | 0.79 $* | 0.16 $* |

| Mar-19-2025 | 0.37 $* | 0.1 $* |

| Feb-19-2025 | 0.61 $* | 0.39 $* |

| Jan-19-2025 | 0.53 $* | 0.89 $* |

Характеристики

Roll press coal briquette machine charcoal powder ball press machine

Roller briquette press machine or roller briquette press is used to briquette the wet materials into the briquette.

Almost all the materials can be used in the roller briquette press machine, the following are some common materials:

Fuel: coal, charcoal, etc

Metal: oxide scale, mill scale, iron, aluminum, ferro silicon, copper, chrome, chromite, manganese, nickel, zinc, etc

Mineral: kaolin, laterite, magnesite, fluorite, fluorspar, silicon, dolomite, etc

Other: lime, plaster, coke, carbon black, gypsum, clay, sludge, converter dust, pigment, etc

For biomass briquette , we recommend to use other briquette machines, like the log briquette maker, screw bio briquettes machine, wood chip compactor and biomass brick briquetter.

Requirement of raw material

1.Size

High quality briquette comes from the small raw material, for common materials, less than 5mm is a good choice for energy saving and usage.

2.Moisture

Moisture is very important in briquetting process, if the material is too wet, it will stick in the roller hole and the machine won’t make briquette anymore, too dry, you can’t even get the shaped briquette.

So, what is the proper moisture for briquetting?

This is different from material to material, and also have something to do with the binder you plan to use.

A binder mixed briquetting process

In the roller briquette press process, the materials need to add binder before briquetting, we have different consideration for the binders, for example, if your material is too wet to briquette, we usually need to dry it, but if the moisture is not that high, we solve the problem by adding some dry binder not only for briquetting also for moisture controlling. The proportion of binder is different for different materials.

Herewith an article for you to learn more about binder: All about binders – make briquette with the proper binder

The briquette ball size

Size can be between 10mm to 110mm.

With further consideration of capacity and the briquette strength, our recommend size is between 25mm to 50mm.

A general single process for roller briquette press machine plant

wet roller briquette plant whole process show

Crusher ⇒ Silo ⇒ Mixer ⇒ Silo ⇒ Briquette Machine ⇒ Dryer

Crusher: If your material is too big, generally, a crusher must be needed, or else that will reduce the working life of the roller. Furthermore get proper size material is also a way to make well binder mixed material;

Silo: Silo is used to store the material for a smooth feeding for the next step;

Mixer: A good binder mixed material will get a high strength briquette as well as the briquette shaping rate. The water (if needed) and binder will be added here;

Dryer: You can choose vertical dryer or belt dryer according to your budget, if you have time and place to dry the briquette, you can even remove this equipment.

| Model | Reducer | Roller size | Power (Kw) | Yield (t/h) | Roller Material | Roller pressure (t/cm) |

| XM290 | ZQ300 | Φ290 | 5.5 | 0.8-2 | 65Mn | 1 |

| XM360 | ZQ350 | Φ360 | 7.5 | 2-3.5 | 65Mn/9Cr2Mo | 1 |

| XM400 | ZQ400 | Φ400 | 11 | 4-5 | 65Mn/9Cr2Mo | 1 |

| XM430 | ZQ400 | Φ430 | 11 | 5-7 | 65Mn/9Cr2Mo | 1-2 |

| XM500 | ZQ500 | Φ500 | 18.5-30 | 6-8 | 65Mn/9Cr2Mo | 1-2.5 |

| XM650 | ZQ650 | Φ650 | 22 | 8-12 | 65Mn/9Cr2Mo | 1-2.5 |

| XM750 | ZQ750 | Φ750 | 30-75 | 12-18 | 65Mn/9Cr2Mo | 1-2.5 |

| XM850 | ZQ850 | Φ850 | 55-90 | 18-25 | 65Mn/9Cr2Mo | 1-2.5 |

| XM1000 | ZQ1000 | Φ1000 | 75-130 | 25-30 | 65Mn/9Cr2Mo | 2-2.5 |

Packing Details : All products will be processed to be rustproof and moisture proof before delivery.

20GP container or 40GP container

Equipment is packed with plastic wrap or steel case, depends on machine weight.

Motro is packed with steel case or wooden case. Control panel is packed with steel case.

Loading container in factory.

Delivery Details : 15-25 days after confirming order,detail delivery date should be decided according to production season and order quantity.