Производители легких блоков кирпичей clc немецкая технология китайская производственная линия машина для производства

- Категория: Brick Making Machinery >>>

- Поставщик: Gongyi,Wanlong,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 77588.16 $* | 81467.83 $* |

| Aug-18-2025 | 76936.61 $* | 80783.85 $* |

| Jul-18-2025 | 64548.83 $* | 67775.71 $* |

| Jun-18-2025 | 75632.63 $* | 79414.49 $* |

| May-18-2025 | 65852.78 $* | 69145.23 $* |

| Apr-18-2025 | 74328.96 $* | 78044.49 $* |

| Mar-18-2025 | 73676.78 $* | 77360.43 $* |

| Feb-18-2025 | 73024.32 $* | 76675.40 $* |

| Jan-18-2025 | 72372.14 $* | 75991.9 $* |

Характеристики

Product Description

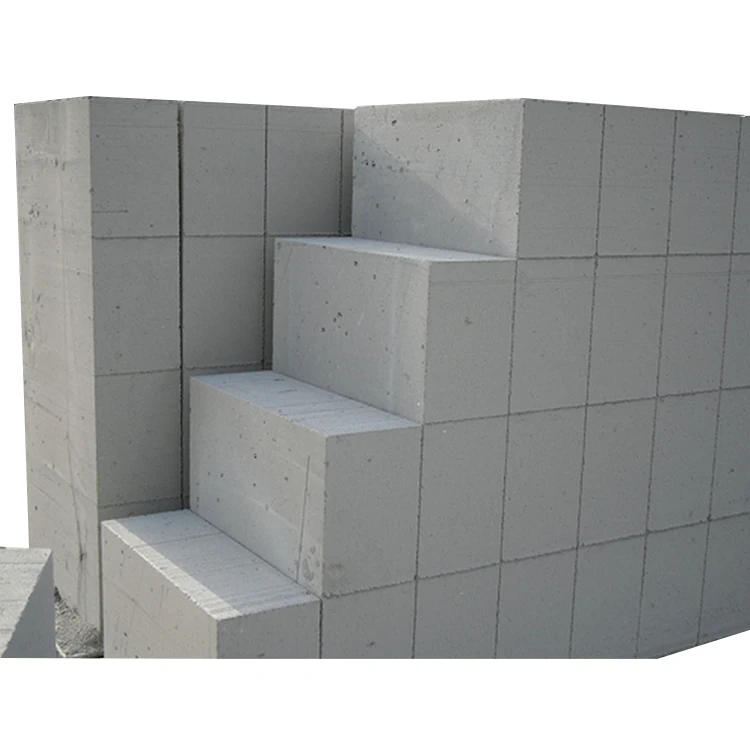

Light weight bricks blocks clc german technology china block production line aac brick making machine

AAC block manufacturing machine plant cost bricks making machine lowest price

AAC and ALC block Foamy brick has good resist compression performance: resist compression strength is more than 0.5Mpa, highest intensity can reach

10.5Mpa above, not craze, service life is long, foamy brick also useful different raw material is made.

Autoclaved Aerated Concrete Block are widely used as external wall panel (exterior wall panel), internal wall panel (interior wall

panel), partition wall panel, flooring, roofing, fence, cladding, curtain wall and facade etc.

10.5Mpa above, not craze, service life is long, foamy brick also useful different raw material is made.

Autoclaved Aerated Concrete Block are widely used as external wall panel (exterior wall panel), internal wall panel (interior wall

panel), partition wall panel, flooring, roofing, fence, cladding, curtain wall and facade etc.

AAC and ALC Non autoclaved aerated foam brick

AAC and ALC Non autoclaved aerated foam brick are widely used in different kinds of buildings, such as public facilities, industrial constructions, steel structure building, warehouse, workshop, stores, hospitals, hotels, apartments, villas, schools, supermarkets etc.

Autoclaved Aerated Concrete Block can replace traditional precast concrete and clay bricks very well. Also the panels can easily cut, drilled, screwed when installing with fast speed due lightweight and precast.

Specification

applied materials

Foam brick (kg/ m³) | Cement (kg) | Filling aggregate (kg) | Water (kg). | Foaming agent (kg) |

400±50 | 154 | 200 | 177 | 0.8-0.9 |

500±50 | 193 | 250 | 221 | 0.7-0.8 |

600±50 | 231 | 300 | 265 | 0.6-0.7 |

700±50 | 270 | 350 | 310 | 0.5-0.6 |

800±50 | 398 | 400 | 354 | 0.45-0.5 |

Cement: ordinary Portland cement 32.5, 42.5, ordinary Portland complex

Cement 32.5, 42.5 (optional) can be, if you want to shorten the production cycle, can use fast hard Portland cement or

sulphoaluminate cement.

1, fill aggregate: according to the local situation selection: fly ash, river sand, stone powder, tailing slag (selection),

aerated powder slag, blast furnace water slag, etc.

2, foaming agent: YX series, foaming agent for foam brick.

3, additives: use YX series, foam brick special additives.

Finished product

Our company

FAQ

F A Q

1. Q: Is your company a manufacturing company or a trading company?

A:We are a direct factory, not an agent or trading company, and the quality and after-sales service are guaranteed.

2. Q: How can I trust the quality of the machine?

A: Our products have passed the ISO 9001-2000 and CE certification. We have 11 years of history in manufacturing machines, with rich experience, updated technical ideas and applications.

3. Q: When will you deliver the goods?

A:Usually 30 days after receiving buyer's deposit and mold confirmation.

4. Q: What are the payment terms?

A: The advance deposit paid by T / T is 30%, and the balance before t / T loading is 70%. You can also choose other trading methods.

5. Q: Would you mind providing video?

A:The video can be sent to you, please contact me.

6. Q: How about the debugging of the machine and the training of the workers?

A:Yes, after the installation of the block production line, our engineers will test and commission, manufacture blocks in the most appropriate proportion, and train workers on how to operate and maintain the machine.

For brick machine manufacturing,

we are professional !