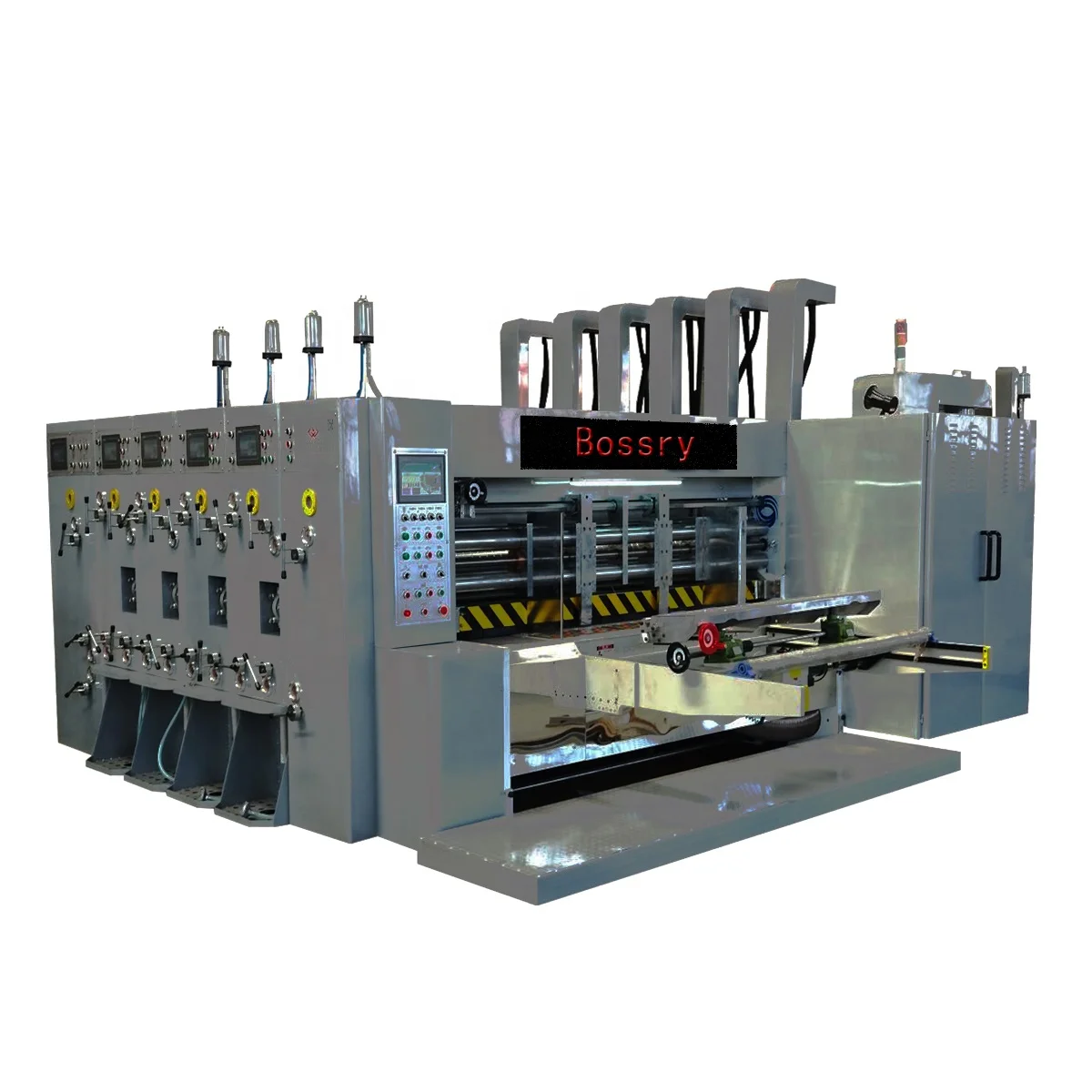

Большой размер картона автоматической 3 цветный гофрированный картон флексографской печати долбежные

- Категория: Carton Printing Slotting Die-Cutting Machine >>>

- Поставщик: Dongguang,Bosirui,Machinery,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 19635.63 $* | 20617.57 $* |

| Aug-16-2025 | 19470.78 $* | 20444.61 $* |

| Jul-16-2025 | 16335.52 $* | 17152.45 $* |

| Jun-16-2025 | 19140.25 $* | 20097.44 $* |

| May-16-2025 | 16665.56 $* | 17498.9 $* |

| Apr-16-2025 | 18810.26 $* | 19751.82 $* |

| Mar-16-2025 | 18645.99 $* | 19577.51 $* |

| Feb-16-2025 | 18480.7 $* | 19404.4 $* |

| Jan-16-2025 | 18315.95 $* | 19231.99 $* |

Характеристики

automatic flexo printing die cutting machine

Function and Characteristics:

1. Designed According the high request and the reliable function,the operation of the machine is humanization,can accomplish the setting,

revision, implement,replacing and memories function in a shot time,and display with a exact data.

2. All the drive rollers adopted high quality steel materials,hard chromium plating and the surface treated by lapping finish.

3.The drive gears adopt high quality alloy steel,after heat treatment and lapping finish.

4.Lubricate oil automatic balance device,keep the equal oil level equal in each unit.

5.The machine adopt PLC control,with automatic zero return"and"memory"function.

6.Use sun feeder for feed the cardboard.

7.Customer can chose use steel anilox roller or ceramic roller,the lines of the anilox roller so can be choose accord the customer use

feeding unit

Feeding Department:

1.The use of the most advanced light pressure leading edge feed system,the system feed speed, high color accuracy, long service life,not easy to quality problems.

2.The use of centrifugal suction fan to do cardboard adsorption tension, not quite flat on the cardboard can suck flat transport.The design has the frequency converter control, may according to the cardboard thickness, the size to control the air volume flexibly,causes the thin paper board not to be easy to damage.

3.Design a centrifugal fan suction on the board printing surface dust removal device.

printing unit

Function of Feeding Department:

1. The diameter of the plate roller with a 410m m (hanging plate with reel shaft type)lateral movement using electric control.

2. The ink roller adopts ceramic roller produced by jiangsu haili. 16. Phi 200mm,20.

500 wire. You can choose any one which you want.

3. The printing rubber shaft is produced in hebei jizhou with a diameter of 190mm.

slotting unit

Function of Slotting Department:

1.With pre-creasing wheels for prevent the cardboard rupture while creasing.

2.Single roller with double knives sloting,the height of the carton adopt PLC and electric input data adjustment.(PLC with touch screen adjustment as an option)

3.The phase of the slotting unit adopt PLC and electric 360°adjust, accord the error to input the adjust data,can be adjusted while the machine running or stop.(PLC with touch screen adjustment as an option)

4.The slotting knives and the creasing wheels horizontal moving adopt electric synchronous adjustment.(PLC with touch screen adjustment as an option,input the size of the carton into the touch screen,will automatic adjusting).

5.Creasing space and knife roller space adjustment adopt self-locking structure.

Die cutting Department:

1.The cardboard molding using circular die cutting molding, die roller phi 360mm(excluding die), fixed template hole distance: horizontal 100mm, radial 18 equal parts.

2.The design of a free version of die cutting device, users can use the device in the processing of ordinary paper can save the cost of making templates, the device design has four knife column manual horizontal movement, phase height four knife synchronous adjustment,adjustment size is fast and convenient.

3.The upper shaft is in the form of hanging sleeve, and the rubber sleeve is made in Germany.

4.The design has the function that the upper shaft starts up and then automatic ally moves back and forth, so that the knife mark part is no longer repeated rolling in order to increase the service life of the rubber sleeve.

Name of parameter | Unit | specification | |||

Width of inside machine | mm | 2400 | 2800 | 3200 | |

Maximum production speed | Pieces/min | 180 | 180 | 180 | |

Maximum feeding size | mm | 900*2000 | 1200*2400 | 1200*2800 | |

Minimum feeding size | mm | 280*600 | 350*700 | 350*700 | |

Skip feeding size | mm | 1100*2000 | 1500*2400 | 1500*2800 | |

Maximum printing size | mm | 840*2000 | 1200*2400 | 1200*2800 | |

Printing precision | mm | ±0.5 | ±0.5 | ±0.5 | |

Printing plant thickness | mm | 7.2 | 7.2 | 7.2 | |

Printing paperboard thickness | mm | 3-11 | 3-11 | 3-11 | |

Minimum slot space | mm | Positive knife:190*160*160*160 | Negative knife:260*60*260*60 | ||

Maximum slot depth | mm | 210 | 300 | 300 | |

Printing roller axle circle-oriented regulating | degree | 360°revolving | 360°revolving | 360°revolving | |

Printing roller axle oriented regulating | mm | ±10 | ±10 | ±10 | |

General power | kw | 30 | 30 | 30 | |

Machine dimension size | mm | 6500*3430*2000 | 7500*4000*2400 | 7500*4500*2400 | |

Machine total weight | kg | 22000 | 2800 | 3200 | |