Автономный контроллер движения DDCS V3.1 3/4 Axis

- Категория: CNC Controller >>>

- Поставщик: YUYONG,INDUSTRY(SHENZHEN),LIMITED

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.87 $* | 0.95 $* |

| Aug-17-2025 | 0.56 $* | 0.32 $* |

| Jul-17-2025 | 0.1 $* | 0.72 $* |

| Jun-17-2025 | 0.10 $* | 0.0 $* |

| May-17-2025 | 0.71 $* | 0.51 $* |

| Apr-17-2025 | 0.9 $* | 0.21 $* |

| Mar-17-2025 | 0.17 $* | 0.71 $* |

| Feb-17-2025 | 0.87 $* | 0.14 $* |

| Jan-17-2025 | 0.25 $* | 0.52 $* |

Характеристики

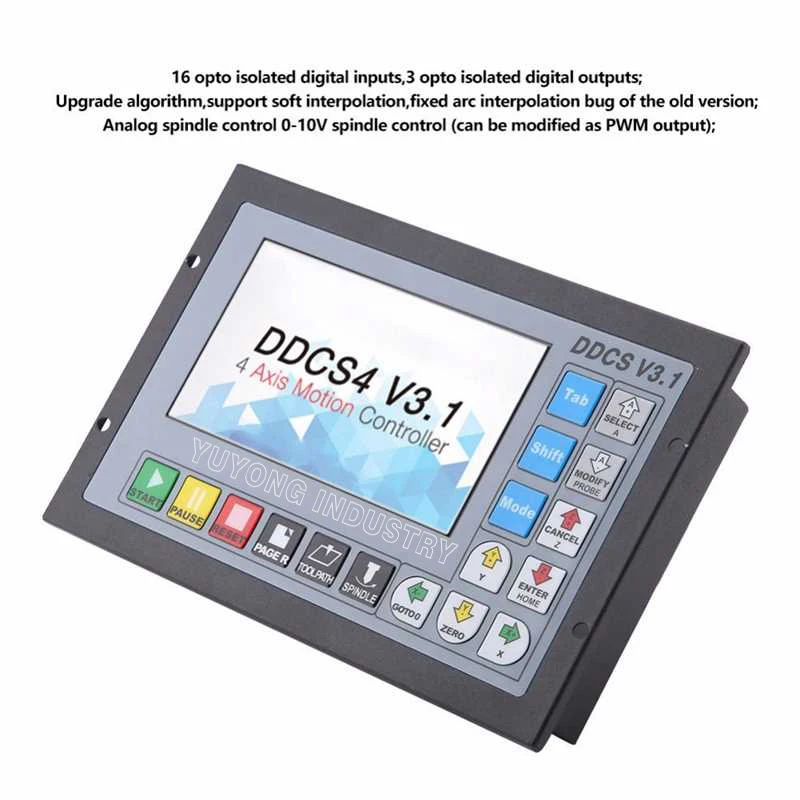

DDCS V3.1 Offline CNC Controller 3/4 Axis

DDCS V3.1 is a product optimized in hardware and software based on the previous version of DDCSV2.1. The control cycle of each position is only 4 milliseconds, and the control precision is high. The maximum single-axis output pulse is 500KHz, the pulse width is adjustable, supporting common stepper motor and servo motor.

DDCS V3.1 is 3 or 4 axis motion controller for stepper and servo systems.DDCS V3.1 numerical control system adopts the ARM+FPGA design framework. ARM controls the human-computer interface and code analysis and the FPGA provides the underlying algorithms and creates the control pulse. This guarantees reliable control and easy operation. The internal operating system is Linux based. The panel layout structure of the CR8-500 is very rational to save space. All operations are controlled by only 17 keys and a

comprehensive G code set is supported.

Specifications:

* 16 opto isolated digital inputs,3 opto isolated digital outputs;

* Upgrade algorithm,support soft interpolation,fixed arc interpolation bug of the old version;

* Analog spindle control 0-10V spindle control (can be modified as PWM output);

* 3-4 axis motor Control.Differential Pulse and direction output signal,Max.500Khz per axis;

* ARM9 main control chip,FPGA core algorithm chip;

* 5 inches TFT screen, resolution ratio: 480×272,17 operation keys;

* 24VDC power input, minimum Current is 0.5A;

* USB flash disk support for G code file input,no size limited of the G-code file;

* 1GB internal memory;

* Support standard MPG;

* Jog function for each axis (continuous, step, defined distance);

* Support the operation of quickly specify the running position;

* Support for “Power Cut” recovery. Data is automatically saved;

* Support the origin and Limit share the same Input ports;

* The controller only support NPN type limited switch.

Explanation of Abbreviations

When operating the DDCS, the users will come across some English abbreviations.The letters of the abbreviation stand for:

* FRO: Feed Rate Override

* SRO: Spindle Rate Override

* SRJ: Jog Speed Setting

* F: Feed rate, unit is mm/min

* S: Spindle Speed, unit rev/min.

* X: The coordinate code of the X axis.

* Y: The coordinate code of the Y axis.

* Z: The coordinate code of the Z axis.

* A: The coordinate code of the A axis

* BUSY: The system is busy. You still can adjust FRO and SRO

* READY: READY mode, any operation can be done

* RESET: Reset mode, controller is in “OFF” mode, no operation can be performed

* CONT: Continuous mode, each axis can be manually jogged with the arrow keys

* Step :Manual Step Mode,each axis can be jogged in defined steps

* MPG: MPG mode. Operate the machine with the MPG (Manual Pulse Generator)

* AUTO: Run G code. Auto is showing when file is processing

Package Includes:

* 1 x DDCSV3.1 CNC Offline Controller (3/4 Axis Optional)

* 1 x 4GB USB Flash Disk

* 1 x USB Extension Cable + Accessories

* 1 x Mounting bracket

When operating the DDCS, the users will come across some English abbreviations.The letters of the abbreviation stand for:

* FRO: Feed Rate Override

* SRO: Spindle Rate Override

* SRJ: Jog Speed Setting

* F: Feed rate, unit is mm/min

* S: Spindle Speed, unit rev/min.

* X: The coordinate code of the X axis.

* Y: The coordinate code of the Y axis.

* Z: The coordinate code of the Z axis.

* A: The coordinate code of the A axis

* BUSY: The system is busy. You still can adjust FRO and SRO

* READY: READY mode, any operation can be done

* RESET: Reset mode, controller is in “OFF” mode, no operation can be performed

* CONT: Continuous mode, each axis can be manually jogged with the arrow keys

* Step :Manual Step Mode,each axis can be jogged in defined steps

* MPG: MPG mode. Operate the machine with the MPG (Manual Pulse Generator)

* AUTO: Run G code. Auto is showing when file is processing

Package Includes:

* 1 x DDCSV3.1 CNC Offline Controller (3/4 Axis Optional)

* 1 x 4GB USB Flash Disk

* 1 x USB Extension Cable + Accessories

* 1 x Mounting bracket