Description |

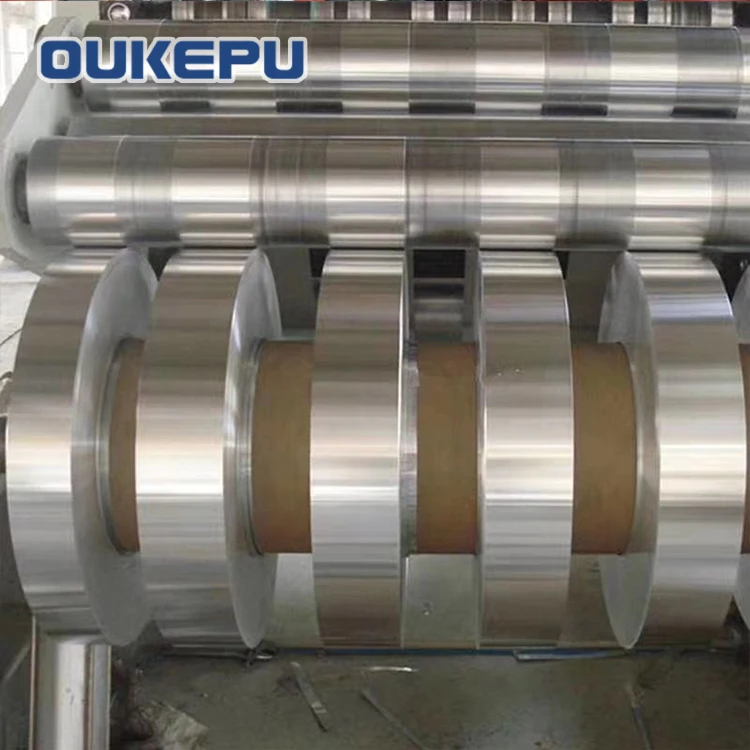

Aluminum strip for electrical transformers winding.

|

Alloy |

1050 1060 3003 3004 8011 1100 |

Temper |

O |

Thickness |

0.1_15.0mm |

Width |

10_1600mm |

Inner Diameter |

300, 400, 500mm |

Resistivity at 20 Degree Centigrade: |

Less than 0.02825Ω. Mm/m |

Surface |

Mill finish |

Edges |

Edges are deburring. |

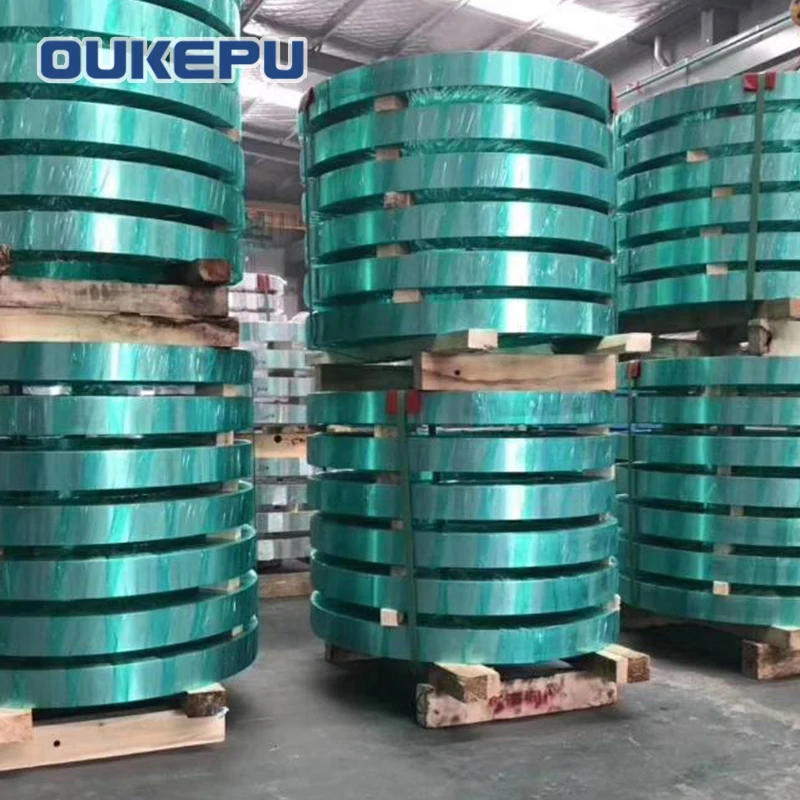

Packing |

Export standard, wooden pallet or wooden case. |

Packing Directionality |

Vertical or Horizontal, based on customer's requirements. |

Application |

Used for low or high voltage transformer winding. |

Chemical Composition |

Alloy |

Alum % |

Impurity Content % |

Fe |

Others |

1060-O temper |

99.6 |

0.30 |

0.10 |

|

In the Fully Anneal Condition with Following Mechanical Properties |

Alloy |

Temper |

Tensile Sterngth (Mpa) |

Elongation |

Resistivity 20℃ |

1060 |

O |

60-95 |

20 |

≤0.02825Ω mm/m |

|

The Maximum resistivity shall be 0.02825 mm2/m at 20y.on average values of Resistivity will be of 0.0275 mm2/m |

Thickness and Tolerances

(mm) |

Width and Tolerances (mm) |

<100 |

100-200 |

201-500 |

501-1250 |

>1251 |

0.1 0.008 |

±0.20 |

- |

- |

- |

- |

0.15 0.012 |

±0.20 |

- |

- |

- |

- |

0.2 0.015 |

±0.20 |

- |

- |

- |

- |

0.3 0.025 |

±0.20 |

- |

- |

- |

- |

0.4 0.03 |

±0.20 |

+0.40 |

- |

- |

- |

0.5 0.03 |

±0.30 |

+0.40 |

- |

- |

- |

0.6 0.03 |

±0.30 |

+0.40 |

- |

- |

- |

0.7 0.03 |

±0.30 |

+0.40 |

+1.0 |

- |

- |

0.8 0.03 |

±0.30 |

+0.50 |

+1.0 |

- |

- |

1.0 0.04 |

±0.30 |

+0.50 |

+1.0 |

+2.0 |

- |

1.1 0.04 |

±0.30 |

+0.50 |

+1.0 |

+2.0 |

- |

1.2 0.05 |

±0.30 |

+0.50 |

+1.0 |

+2.0 |

- |

1.4 0.05 |

- |

- |

+1.0 |

+2.0 |

+2.5 |

1.6 0.05 |

- |

- |

+1.0 |

+2.0 |

+2.5 |

1.8 0.06 |

- |

- |

+1.0 |

+2.0 |

+2.5 |

2.0 0.07 |

- |

- |

+1.0 |

+2.0 |

+2.5 |

|

Quality Control |

![06]() ![14]() ![20]() ![03]() ![strip]() |