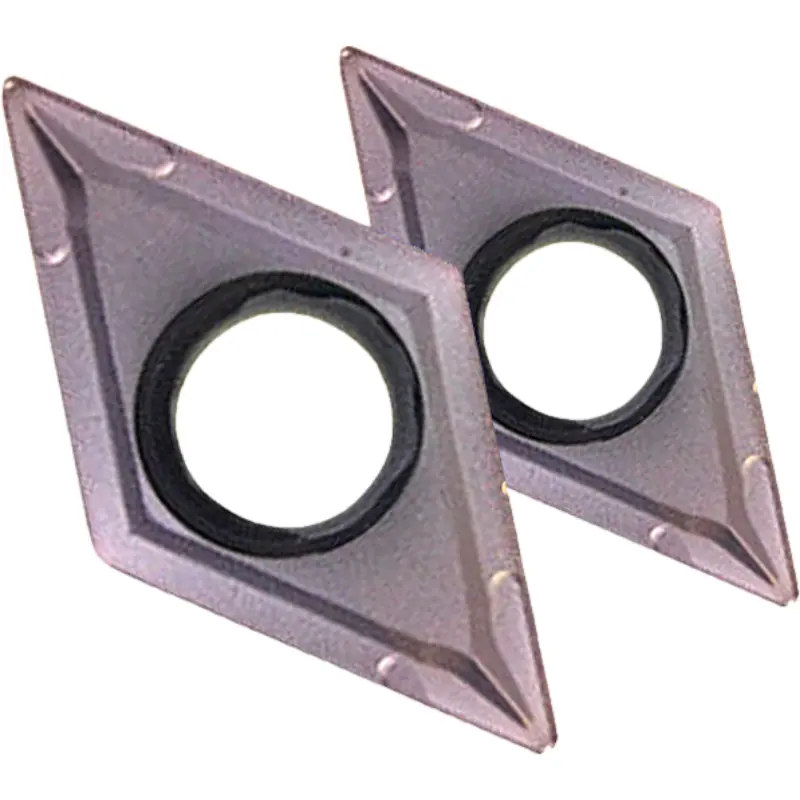

Токарные инструменты токарные резцы из цементированного карбида используемые для токарных

- Категория: Turning Tool >>>

- Поставщик: Zhuzhou,Jingfeng,Carbide,Tools,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.73 $* | 0.79 $* |

| Aug-17-2025 | 0.67 $* | 0.33 $* |

| Jul-17-2025 | 0.98 $* | 0.3 $* |

| Jun-17-2025 | 0.41 $* | 0.68 $* |

| May-17-2025 | 0.36 $* | 0.26 $* |

| Apr-17-2025 | 0.39 $* | 0.19 $* |

| Mar-17-2025 | 0.80 $* | 0.83 $* |

| Feb-17-2025 | 0.46 $* | 0.90 $* |

| Jan-17-2025 | 0.28 $* | 0.93 $* |

Характеристики

Cemeted Carbide Shims

Indexable Tungsten carbide Insert shims for CNC turning tools

Carbide Wood Turning Tools Metal turning tools

Carbide Shims Used For Turning Inserts

Because the surface of the sipe will become uneven after finishing, add a harder and flatter gasket under the blade, that is, the shim, which can prevent the blade from cracking due to excessive pressure and ensure the blade body Does not cause damage.

The function of the spring plate is to lift the wedge in time when the clamping screw is loosened, so as to prevent it from being tightly locked and not easy to loosen.

The user clamping and convenient replacement method, only need to use a wrench to complete the replacement of the blade and pad.

JINGFENG SALE TEAM :

THE MATERIAL USAGE OF EACH GRADE OF CEMENTED CARBIDE:

K30 is suitable for processing cast iron, non-ferrous metals and their alloys, non-metallic materials, etc.

K20 is suitable for rough machining of cast iron and light alloy, and can also be used for milling of cast iron and low alloy steel.

K10 is suitable for finishing and semi-finishing of cast iron and non-ferrous metals. It can also be used for machining of hardened steel and hardened steel.

YS25 is suitable for processing carbon steel, cast steel, high manganese steel, high strength steel and gold steel.

YS2T is an ultra-fine particle alloy with good wear resistance and high impact resistance. It is suitable for finishing and semi-finishing of stainless steel and ordinary alloy steel.

YW1 is suitable for hard-to-machine steels such as heat-resistant steel, high manganese steel, stainless steel and alloy steel, as well as for fine milling and fine milling of ordinary steel and cast iron.

F A Q

Q1: Are you a factory?

A1:Yes,we are a professional manufacturer with more than 30 years experience,and welcome you visit our factory in ZHUZHOU CITY OF CHINA.

Q2:Is it safe for me to pay you to do business?

A2.Yes, sure, we are an honest company,Business should not be done only once. Our goal is to establish a long-term business relationship with you, so that this company can go further.

And Alibaba platform will also protect the interests of buyers.

Q3: How to place an order to you?

Answer:

Step 1: Please send your purchase list or customized product drawings to me,I'll make a quotation to you.

Step 2: After getting your confirmation,I will make the contact or PI(proforma invoice) to you ,signed by the two parties.

Step 3: You pay the deposit to us. We start to prepare the goods and send it to you on time.

During the transportation of the goods, we will continue to follow up the cargoes.

Q4:How long is the delivery time

A4: If the goods you ordered are in stock it needs about 3-5days to send out.

If your order items are out of our inventory, we need 10-30 days to produce or make it.

We will let you know the approximate delivery of the futures before you confirm the order, and deliver on time.

Q5:What are your payment methods?

A5: We can accept payments by ALIBABA online credit guarantee payment, or T/T, L/C, WU,Money Gram,Paypal and so on.

WHY DO I SUGGEST YOU CHOOSE JINGFENG

AS YOUR SUPPLIER?

1.China is the country with the largest tungsten storage capacity in the world, and Zhuzhou is the city with the largest volume of cemented carbide products in China. It has a history of more than 70 years from the 1850s to today. Zhuzhou is also called "China's hard The City of Alloys".

We can provide better tools for many countries around the world, and can take a big step forward for your production process. Let us work together to shape a better future for manufacturing.

2. Our company is also a highly professional and technical company. Our sales team is highly efficient and dedicated and loves work. Online tools remain online for 12 hours to provide you with one-stop services such as product, design, and after-sales technical support. Fast delivery, full follow-up service.

If you need to check the original authentication certificates, please contact me.

Thank you for visiting our website!

The founder of our company, Mr. Hu, is an engineer with 30 years of experience in the manufacture of cemented carbide products.

Our domestic business is doing very well, only to open the Alibaba international website in 2021 to make foreign trade orders.

You can trust our technology and services,welcome you to support our business!

We must do the best for you, I am Linda, I am waiting for you in China!

Linda

Sales Manager

Zhuzhou Jingfeng Carbide Tools Co., Ltd

Address: Building B7-A, Xinma Jingu Industrial Park, Tianyi Road No.959, Tianyuan District, Zhuzhou City, Hunan Province, China

Zip code:412007

Mobilephone:+86 15200435551

https://zzjf.en.alibaba.com

ABOUT US:

Zhuzhou Jingfeng Carbide Tools Co., Ltd was established in 2004. It is located in the largest cemented carbide manufacturing base of China-the National High-tech Industrial Development Zone, Zhuzhou City, Hunan Province. It is a high-tech enterprise integrating the research and development, production, sales and technical services of carbide cutting tools.

The company has advanced and precise processing and testing equipment, and has established a complete cemented carbide production and processing line, focusing on cutting blades, CNC blades, non-slip cemented Carbide small bricks, saw tips, serrated blades, spiral blades for welding, cemented carbide plates, cemented carbide rods and customized or Non-standard shape products etc.

The company has passed ISO9001 quality management system certification. It has a complete variety, excellent technology, superior performance, and a strong supply capacity. After nearly 20 years of development, It is exported to many countries in the world such as Europe, North America, Asia and so on.

Our products are applicable to electronic communication, light industry manufacturing, automotive, Marine, instrumentation, mechanical engineering, aerospace, oil drilling, medical equipment, and other fields.

In the future, we will continue to uphold the concept of "Exquisitely, Sophisticatedly and with craftsman spirit", concentrate on research, go forward, and develop a better future for manufacturing.