Деревообрабатывающий фрезерный станок с ЧПУ для дерева фанеры МДФ акрила 1325

- Категория: >>>

- Поставщик: Jinan,Bcamcnc,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.95 $* | 0.56 $* |

| Aug-16-2025 | 0.46 $* | 0.36 $* |

| Jul-16-2025 | 0.59 $* | 0.46 $* |

| Jun-16-2025 | 0.37 $* | 0.21 $* |

| May-16-2025 | 0.42 $* | 0.42 $* |

| Apr-16-2025 | 0.98 $* | 0.69 $* |

| Mar-16-2025 | 0.21 $* | 0.1 $* |

| Feb-16-2025 | 0.9 $* | 0.12 $* |

| Jan-16-2025 | 0.53 $* | 0.13 $* |

Характеристики

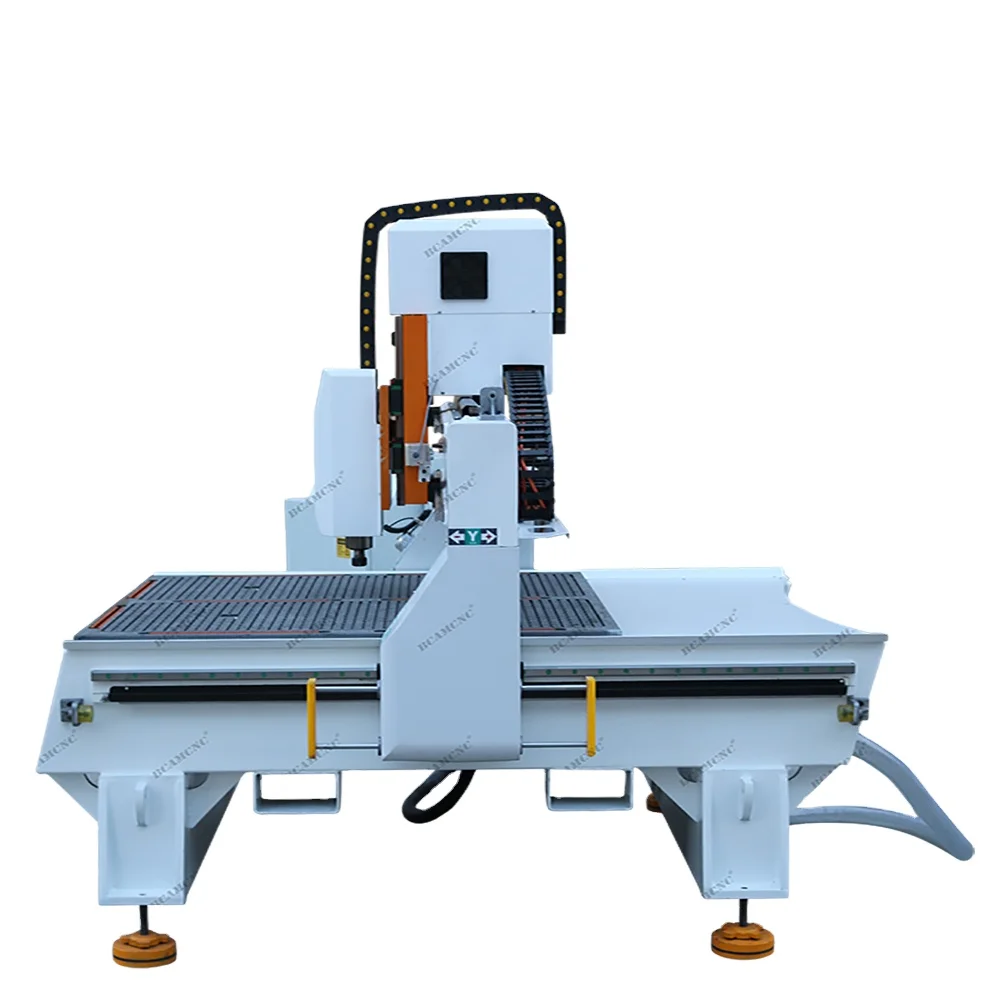

Woodworking cnc router for wood, plywood, MDF, acrylic 1325 wood CNC router machine

Details Images

Products Description

Rich Auto A11 Control System.

BCAM S series cnc router control system is famous DSP A11 which is simple and easy to operate, the system has a wide range of support documents, power-off continuous carving, 2D 3D relief and other functions, easy to operate, widely used.

Air Cooling Spindle.

BCAM S series selects air cooled spindle, power range: 3.0KW-9.0KW. Choose from manual, quick-release, high-power and

high-speed spindles for optimum processing of rigid sheet materials.

high-speed spindles for optimum processing of rigid sheet materials.

BCAM Patent - Active Safety System.

BCM1325D series also has the unique safety protection system of BCAM products, providing external emergency stop function for

equipment users. This function can effectively protect the personal safety of the equipment users, meet the European safety CE

standards, and is very popular among users.

equipment users. This function can effectively protect the personal safety of the equipment users, meet the European safety CE

standards, and is very popular among users.

Rail device

BCAM S series cnc router rail system adopts Taiwan's HIWIN high-quality rail. This guide rail makes BCM1325A-Plus work more accurately. The high quality pulley quality and excellent dustproof system also make BCAMCNC equipment last longer.

lubrication System

lubricating system, one touch can finish periodic maintenance easily.

Leadshine stepper motor and driver

China Best stepper motor and driving system ensures machine to run with fast speed and low noise.

Product Parameter

Parameters | Standard Specifications BCM1325Aplus |

X,Y,Z Working Area | 1300*2500*200mm|4*8ft |

Optional Woking Area | 1300*1300*200mm|4*4ft |

Optional Woking Area | 1500*3000*200mm|5*10ft |

Optional Woking Area | 2000*3000*200mm|6*10ft |

Optional Woking Area | 2000*4000*200mm|6*13ft |

Optional Woking Area | 2000*6000*200mm|6*20ft |

Spindle Power | 3.0kw water cooling spindle |

X,Y,Z Traveling Positioning Accuracy | ±0.01/2000mm |

Table Surface | Vacuum table+T-solt table |

X,Y,Z Rail and Trasmission | X,Y axis gear transmission, Z axis Taiwan TBI Ball Screw |

Max. Rapid Travel Rate | 70m/min |

Max.Working Speed | 50m/min |

Cutting Thickness | According materials |

Spindle Speed | 6000-24000RPM |

Drive Motors | Leadshine stepper motor and drivers |

Working Voltage | AC380V/50hz/3 phase |

Command Language | G Code |

Operating System | DSP Rich Auto A11 control system |

Interface | USB |

Software Compatibility | Option:Type 3/Ucancam/Alphacam/Solidworks, etc. |

Running Enviroment | Temperature:0℃~45℃Relative Humidity:30%~75% |

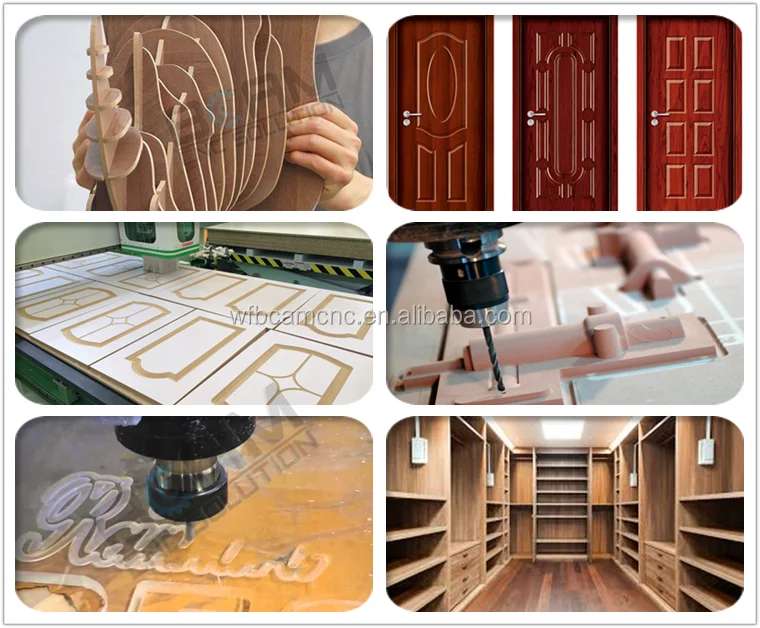

Sample display

Woodworking like furniture

Sign industrial

Soft metal cutting and carving

3D Carving

Product packaging

Wooden package

Firstly,Packed the cnc router machine with plastic sheet for clearing and damp proofing.

Secondly,Then put the cnc router machine in the plywood case for safety and clashing.

Thirdly,Transport the plywood case into the container.

Secondly,Then put the cnc router machine in the plywood case for safety and clashing.

Thirdly,Transport the plywood case into the container.

Company Profile

Recommend Products

FAQ

Is important to note that some materials like Aluminum, require cooling during the actual milling operation. The heat generation

means that chips can clog or glue the flutes of the milling machine and the milling tool breaks. Suitable coolants and lubricants can be found in the range of most CNC milling machine manufacturers.

With these four questions I quickly find out which CNC Router is suitable for my needs:

1.What size are my workpieces to be processed?

2.What engine power do I need for my hard / soft material?

3.How hard are the materials to be processed concerning the required torsional stiffness of the machine?

4.How exactly is the selected CNC Router adapted to my desired materials

means that chips can clog or glue the flutes of the milling machine and the milling tool breaks. Suitable coolants and lubricants can be found in the range of most CNC milling machine manufacturers.

What criteria are decisive when buying a BCAM CNC Router? If you have decided to buy a BCAM CNC Mill to facilitate some work or to make special work possible, immediately one question comes to mind: “What do I have to consider when buying a CNC Router?

* The size

Before I search for a suitable manufacturer, I should have a good idea of in which size I want to edit the desired material.

Because the maximum traveldictates the maximum size of my workpiece. Do I perhaps prefer to process larger workpieces? Then I should observe the maximum travel of the selected machine.

Before I search for a suitable manufacturer, I should have a good idea of in which size I want to edit the desired material.

Because the maximum traveldictates the maximum size of my workpiece. Do I perhaps prefer to process larger workpieces? Then I should observe the maximum travel of the selected machine.

* The motor and its performance

Furthermore is crucial which materials I would like to process because this depends on the required performance of the milling spindle. Soft materials such as wood consume significantly less drive power than hard metals such as steel or cast steel. Here a competent milling machine manufacturers will be happy to advise you.

Furthermore is crucial which materials I would like to process because this depends on the required performance of the milling spindle. Soft materials such as wood consume significantly less drive power than hard metals such as steel or cast steel. Here a competent milling machine manufacturers will be happy to advise you.

* Hardness and toughness of the material

Also concerning the torsional rigidity of the machine, the material to be processed is crucial. Soft materials will demand the milling machine other than hard materials, such as aluminium and steel. The harder a material is, the stiffer the CNC Router should be built. Only in this way a high accuracy in hard materials, especially metals, are guaranteed.

Also concerning the torsional rigidity of the machine, the material to be processed is crucial. Soft materials will demand the milling machine other than hard materials, such as aluminium and steel. The harder a material is, the stiffer the CNC Router should be built. Only in this way a high accuracy in hard materials, especially metals, are guaranteed.

* Precision

A CNC Router Machine should be as well adapted to the material to be machined as possible. Someone who workes mainly wood should get a one-on tailored CNC machine. The more accurately the machine fits the demands of the material, the more accurate the milling results.

A CNC Router Machine should be as well adapted to the material to be machined as possible. Someone who workes mainly wood should get a one-on tailored CNC machine. The more accurately the machine fits the demands of the material, the more accurate the milling results.

With these four questions I quickly find out which CNC Router is suitable for my needs:

1.What size are my workpieces to be processed?

2.What engine power do I need for my hard / soft material?

3.How hard are the materials to be processed concerning the required torsional stiffness of the machine?

4.How exactly is the selected CNC Router adapted to my desired materials