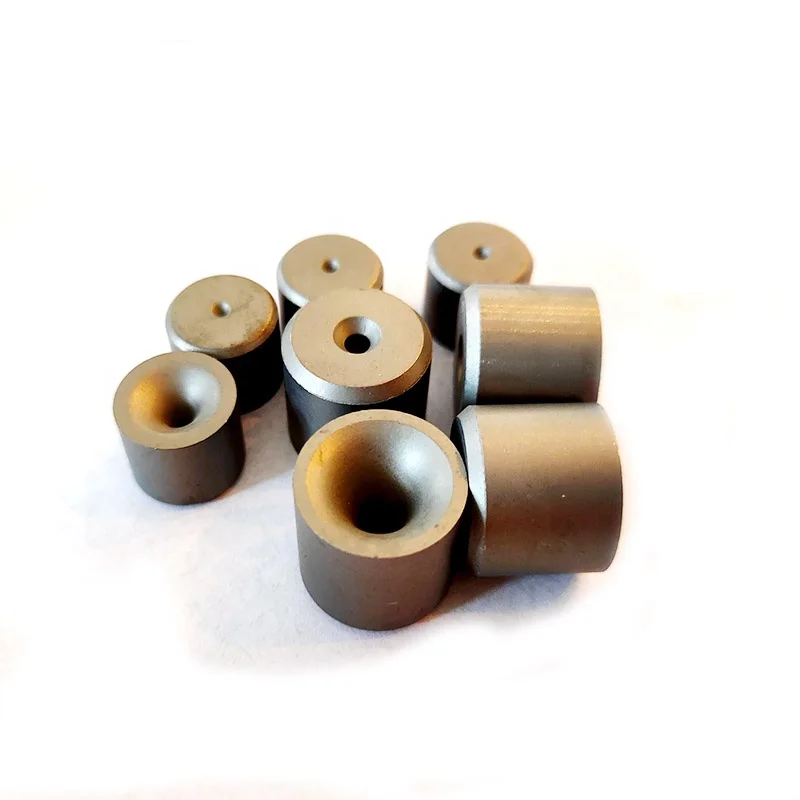

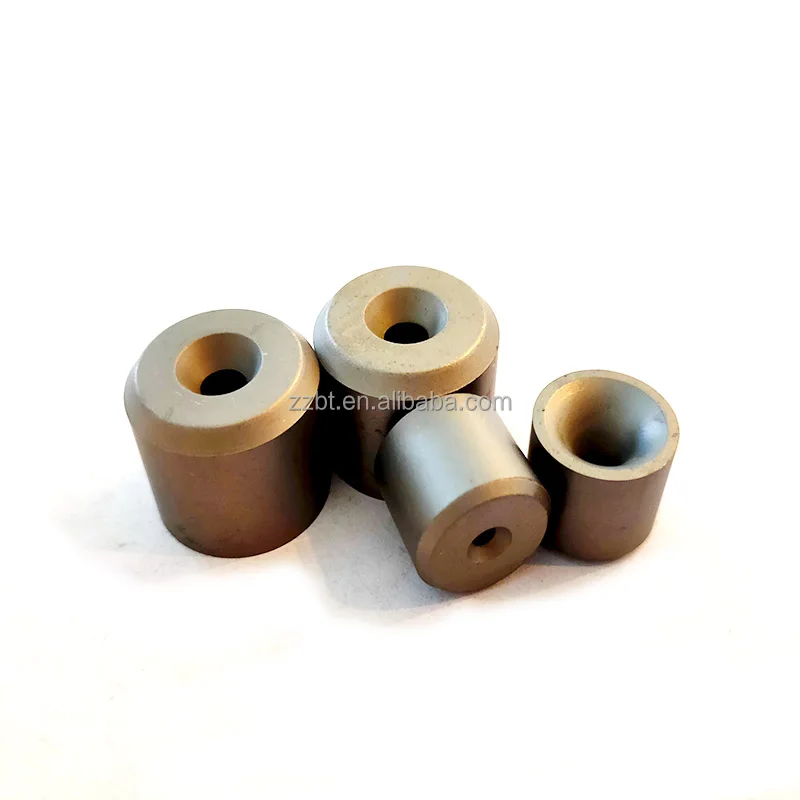

YG8 пустые наконечники из карбида вольфрама для черчения

- Категория: Tool Parts >>>

- Поставщик: Zhuzhou,Better,Tungsten,Carbide,Co.,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 6298.49 $* | 6424.1 $* |

| Jul-16-2025 | 5108.86 $* | 5210.29 $* |

| Jun-16-2025 | 6199.92 $* | 6323.65 $* |

| May-16-2025 | 6149.79 $* | 6272.42 $* |

| Apr-16-2025 | 4909.25 $* | 5007.67 $* |

| Mar-16-2025 | 6050.67 $* | 6171.76 $* |

| Feb-16-2025 | 6000.56 $* | 6120.72 $* |

| Jan-16-2025 | 5951.36 $* | 6070.62 $* |

Характеристики

Product Name | Tungsten Carbide Drawing die |

Material | Tungsten carbide |

Size | Can customize |

Application | It is widely used in wire drawing industry |

Wire drawing dies are commonly used to reduce the diameter of various ferrous and non-ferrous rods and wires. Applications include high, medium and low voltage cables, automotive, medical wire, superconducting, bonding, and welding wires.

Our Tungsten Carbide Drawing Die is engineered for precision and durability, making it the ideal choice for a wide range of wire and rod drawing applications. Crafted from high-quality tungsten carbide, these dies offer exceptional hardness and wear resistance, ensuring consistent performance and extended tool life in the most demanding manufacturing environments.

Upgrade Your Drawing Machine !

BENEFITS

Applicable Industries

- **Metalworking**: Ideal for industries involved in wire and rod production.

- **Manufacturing**: Used in various manufacturing sectors where precision metal forming is essential.

- **Automotive**: Suitable for producing components requiring high tensile strength materials.

- **Electronics**: Utilized for snug fitting wire products in electronic applications.

1.Ideal for ferrous rod-size wire

2.Ideal for short and trial runs

3.Carbide grade tailored to wire material when required

4.Special coatings available to reduce friction and/or increase durability 5.Cast & helix control available

KEY FEATURES

KEY FEATURES

1.Custom case sizes available

2.Various carbide grades available

3.Low cost dies 4.Starting from 0.1 mm

- **High Hardness**: Tungsten carbide is one of the hardest materials available, providing superior resistance to wear and deformation during the drawing process.

- **Precision Engineering**: Manufactured to tight tolerances, our drawing dies ensure accurate dimensions, resulting in high-quality finished products.

- **Durability**: With excellent impact resistance, these dies maintain their shape and functionality even under extreme conditions, reducing downtime and replacement costs.

- **Heat Resistance**: Capable of withstanding high temperatures, our tungsten carbide drawing dies perform reliably in both cold and hot drawing applications.

- **Versatile Applications**: Suitable for a variety of materials, including steel, copper, and aluminum, these dies are perfect for different wire and rod sizes.

- **Precision Engineering**: Manufactured to tight tolerances, our drawing dies ensure accurate dimensions, resulting in high-quality finished products.

- **Durability**: With excellent impact resistance, these dies maintain their shape and functionality even under extreme conditions, reducing downtime and replacement costs.

- **Heat Resistance**: Capable of withstanding high temperatures, our tungsten carbide drawing dies perform reliably in both cold and hot drawing applications.

- **Versatile Applications**: Suitable for a variety of materials, including steel, copper, and aluminum, these dies are perfect for different wire and rod sizes.

Technical Specifications

- **Material**: Tungsten carbide

- **Sizes**: Available in various diameters and shapes; customizable based on customer requirements

- **Hardness**: Typically around 90 HRA

- **Temperature Range**: Effective in applications up to 800°C

- **Applications**: Wire drawing, rod drawing, and other metal forming processes

- **Sizes**: Available in various diameters and shapes; customizable based on customer requirements

- **Hardness**: Typically around 90 HRA

- **Temperature Range**: Effective in applications up to 800°C

- **Applications**: Wire drawing, rod drawing, and other metal forming processes

Applicable Industries

- **Metalworking**: Ideal for industries involved in wire and rod production.

- **Manufacturing**: Used in various manufacturing sectors where precision metal forming is essential.

- **Automotive**: Suitable for producing components requiring high tensile strength materials.

- **Electronics**: Utilized for snug fitting wire products in electronic applications.

Usage Instructions

1. **Setup**: Ensure the drawing die is securely mounted in the drawing machine and aligned correctly with the wire feed.

2. **Wire Preparation**: Clean and prep the wire or rod to remove any contaminants that may affect the drawing process.

3. **Drawing Process**: Monitor the drawing speed and pressure to maintain consistent quality, ensuring that the wire moves smoothly through the die.

4. **Maintenance**: Regularly inspect and clean the dies to prolong their lifespan and performance.

1. **Setup**: Ensure the drawing die is securely mounted in the drawing machine and aligned correctly with the wire feed.

2. **Wire Preparation**: Clean and prep the wire or rod to remove any contaminants that may affect the drawing process.

3. **Drawing Process**: Monitor the drawing speed and pressure to maintain consistent quality, ensuring that the wire moves smoothly through the die.

4. **Maintenance**: Regularly inspect and clean the dies to prolong their lifespan and performance.

For optimal performance and safety, always adhere to the manufacturer’s guidelines and recommendations. Ensure proper handling and storage of dies to prevent damage.

For further information or to discuss custom orders, please contact our dedicated sales team. We are committed to providing you with the best solutions for your drawing needs!