Цена по прейскуранту завода-изготовителя одножильный провод THQ50C медным покрытием сварочная проволока ER70S-6 0 8 мм 1 2 mig сварщиков припойная для сварки газовые

- Категория: Welding & Abrasives >>>

- Поставщик: Tianjin,Bridge,Welding,Materials,Group,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 17.11 $* | 17.93 $* |

| Jul-19-2025 | 13.38 $* | 13.80 $* |

| Jun-19-2025 | 16.75 $* | 16.20 $* |

| May-19-2025 | 16.33 $* | 16.34 $* |

| Apr-19-2025 | 13.39 $* | 13.2 $* |

| Mar-19-2025 | 16.17 $* | 16.7 $* |

| Feb-19-2025 | 16.39 $* | 16.9 $* |

| Jan-19-2025 | 16.40 $* | 16.25 $* |

Характеристики

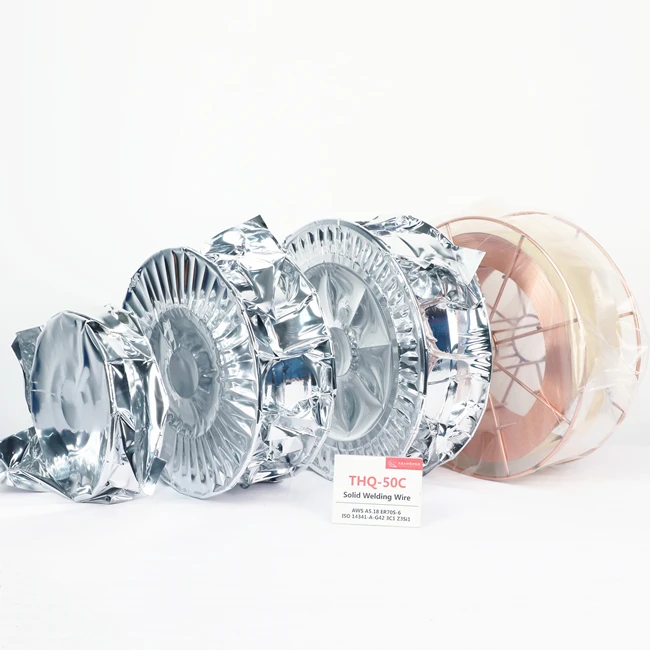

PRODUCT DISPLAY |

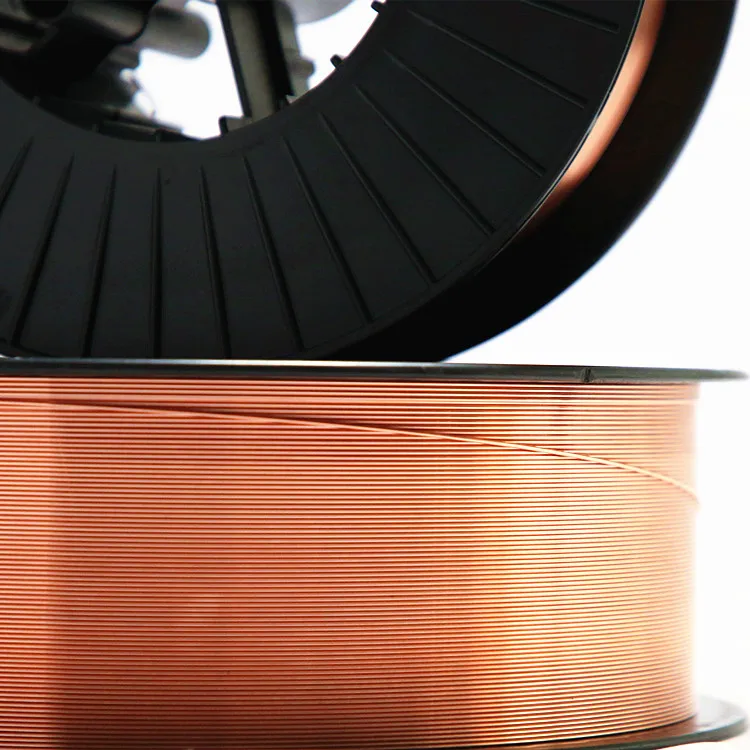

THQ-50C

Solid welding wire for gas shielded welding

GB/T8110 ER50-6

ISO 14341-A-G42 3C1 Z3Si1

AWS A5.18 ER70S-6

Applications: It can be used in tee welding of carbon steel and low alloy steel in the corresponding strength grade, which can be used in engineering machinery, ship, vehicle manufacturing, petrochemical and other industries.

Characteristics: wire THQ-50C is 500MPa level carbon steel wire. It take CO2 or 80%Ar+20%CO2 gas shielded arc welding. The welding spatter is small, and it has beautiful appearance, high cladding efficiency and small weld metal porosity sensibility. The welding technology of all positions is good.

Precautions:

1.Clear rust, oil, water and other impurities on the weldments before welding.

2.The size of the welding line energy will directly affect the mechanical properties of the weld. The size of the line energy depends on the important level of the structure. The more important the structure is, the smaller the line energy should be taken.

3.Welding parameters are only provided for reference. The user should develop an appropriate production welding specifications acccording to the circumstances.

Chemical composition of the welding wire (mass fraction): %

Items | C | Mn | Si | S | P | Ni | Cr | Mo | V | Cu |

Standard value | 0.06-0.15 | 1.40-1.85 | 0.80-1.15 | ≤0.025 | ≤0.025 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.03 | ≤0.50 |

Case of value | 0.08 | 1.50 | 0.89 | 0.012 | 0.013 | 0.03 | 0.02 | 0.002 | 0.003 | 0.11 |

X - Ray Detection: Grade II

Mechanical properties of deposited metal: (CO2)

Items | Tensile strengthRm/MPa | Yield strength Rel/Rp0.2 MPa | Elongation A/% | Charpy V-notch impact energy KV2(J)-30℃ |

Standard value | ≥500 | ≥420 | ≥22 | ≥27 |

Case of value | 560 | 450 | 26 | 108 |

Welding reference current : (DC +)

Welding wire diameter(mm) | 0.8 | 1.0 | 1.2 | 1.6 |

Welding current(A) | 50-180 | 70-230 | 80-350 | 120-500 |

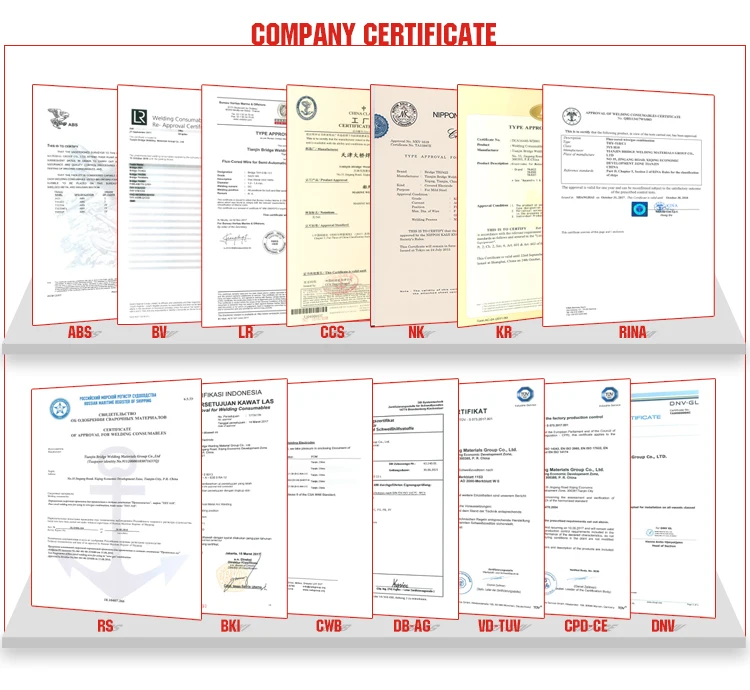

Classification Society Certification:

Ship inspection agency | ABS | BV | CCS | DNV | GL | LR | NK | KR | CWB |

level of recognition | 3YSAH10 | SA3YMHH | 3YSH10 | ⅢYMS(H10) | 3YS | 3YSH15 | KSW53G(C)H10 | 3YSG(C)H10 | B-G49A3CG6 |

EU certification:

Certification body | CPD-CE steel structure certification |

Model | G42 3 C1 Z3Si1 |

| PRODUCT APPLICATION |

Some of our products have been applied to overseas key projects.

Electrode, SAW wire and flux of 600MPa Grade & 800MPa Grade

applied to hydro steel at Laos pumped storage power station

E6010 cellulose electrode Applied to the Ghana TEMA pipeline project in Africa successfully. It breaks the monopoly of Bohler cellulose electrode and won the bidding of oil pipeline Ghana tank project

| RELATED PRODUCTS |

| Welding Wire | Flux Cored Welding Wire |

| MORE >> | MORE >> |

A     |

| F A Q |

Q: what is delivery time / lead time ?

A: 30 days

Q: what is your minimum order ?

A: 5000kgs

Q: what is your payment term ?

A: 1- 30% down payment for order confirmation, 70% before shipment.

2- 100% at sight LC

Q: can we visit your factory ?

A: yes you can at your free time.