Лидер продаж небольшая сушильная машина из нержавеющей стали 4 кг 5

- Категория: Freeze Drying Equipment >>>

- Поставщик: Sinoped,International,(Liaoning),Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 23800.55 $* | 24990.89 $* |

| Aug-16-2025 | 23600.54 $* | 24780.14 $* |

| Jul-16-2025 | 19800.40 $* | 20790.60 $* |

| Jun-16-2025 | 23200.75 $* | 24360.59 $* |

| May-16-2025 | 20200.33 $* | 21210.94 $* |

| Apr-16-2025 | 22800.88 $* | 23940.14 $* |

| Mar-16-2025 | 22600.91 $* | 23730.71 $* |

| Feb-16-2025 | 22400.82 $* | 23520.72 $* |

| Jan-16-2025 | 22200.65 $* | 23310.40 $* |

Характеристики

Medicine freeze-drying includes two parts: Western medicine and Chinese medicine. Freeze-drying of western medicine has developed in China, and many larger pharmaceutical factories have freeze-drying equipment. In terms of injections, freeze-drying processes are used more frequently, which improves the quality and shelf life of medicines, and brings benefits to both doctors and patients. However, there are not many varieties of freeze-dried medicines, the product prices are high, and the drying process is not advanced. In terms of traditional Chinese medicine, it is currently only limited to the freeze-drying of a small amount of Chinese medicinal materials such as ginseng, velvet antler, yam, and cordyceps. A large number of Chinese patent medicines have not yet adopted the freeze-drying process, which is far behind foreign countries. A few years ago, Japan launched the "Western Preparation of Chinese Medicines", which changed the boiling method of Chinese medicines, solved the traditional Chinese medicine

cannot be made into injections or tablets, and solved the problem that Chinese medicines do not cure acute diseases.

Therefore, the freeze-drying process of Chinese medicines in my country And product research has great potential to be tapped. In the fieldof biotechnology products, freeze-drying technology is mainly used for the production of drugs such as serum, plasma, vaccines, enzymes, antibiotics, hormones; biochemical inspection drugs, immunology and bacteriological inspection drugs; blood, bacteria, arteries, bones , Skin, cornea, nerve tissue and various organs for long-term preservation.

At present, freeze dryers are mainly used in the following aspects:

1. Biological products and pharmaceuticals: such as the preservation of antibiotics, antitoxins, supplies and vaccines. In this regard, the use and development of freeze dryers is growing in a trend.

2. Biological tissues and biological specimens: such as dry preservation of skin, bones, aorta, heart valves

and other peripheral tissues used for animal xenogeneic or allogeneic transplantation; making various animal and plant specimens.

3. Nutritional products, especially nutritional products and Chinese herbal medicines: such as royal jelly, honey, pollen, Chinese herbal medicine preparations, etc., the use of freeze dryers is increasing.

4. Microorganisms and algae: such as long-term preservation of various bacteria, yeasts, enzymes, protozoa, microalgae, etc.

5. Make small tissue slices for optical microscopes, electron scanning and transmission microscopes.

6. Food drying: such as coffee, tea, durian, meat, fish and eggs, seaweed, fruits, vegetables, seasonings, tofu, convenience foods, etc.

7. Preparation of ultra-fine powder: such as preparing ultra-fine powder such as Al2O3 and Ba2Ti9O20.

8. Other aspects: For example, the catalyst in chemical industry can increase the catalytic efficiency by 5-20 times after freeze-drying; freeze-dry plant leaves and soil to study the influence of soil, fertilizer and

climate on plant growth and the role of factors; Wet wooden cultural relics, flooded book manuscripts, etc. are dried by

freeze-drying method, which can keep the original condition to the greatest extent.

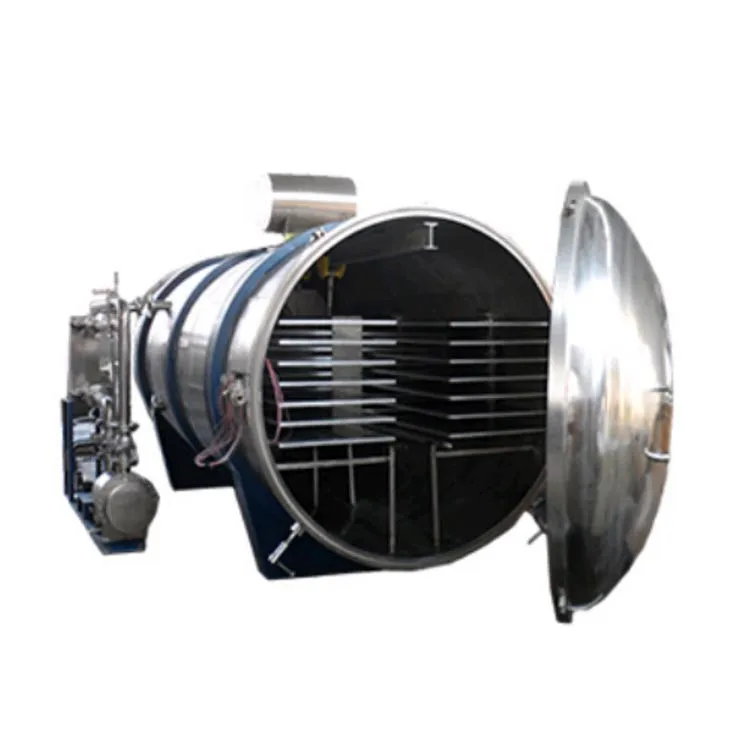

The vacuum freeze drying equipment is an advanced method for the material for the material dewatering.ATALAS technology from THE DENMARK. It has been very famous for its good results. It freezes the moisture material in the low temperature and makes the water inside sublimate directly in the vacuum condition. Then it collects the sublimated vapor by means of the condensing way so as to dewater and dry the material.

Being processed by the vacuum freeze dryer, the physical, chemical and biological states of the material are basically unchanged. The volatile and nutritious contents in the material, which are easy to be denatured in a warm condition, will be lost a little. When the material is freezing dried, it will be formed into a porous one and its volume be basically the same to that before drying. Therefore, the processed material can be recovered quickly if being watered again, because of its large contacting area and it can be stored for a long period in a sealed vessel.

Main Features:

The LG-100 vacuum freeze-drying equipment was identified by the Ministry of Science and Technology as the 2002 National New Product Program Supporting Enterprise. Freeze-dried food will bring you benefits. It can maintain the original color, aroma, taste, form, protein and vitamins of the food. Natural, no preservatives, excellent preservation ability. Excellent packaging life and corresponding shelf life under well-packaged conditions. Can be stored at room temperature, so no complicated cold chain is needed, ie no cold storage/refrigerated transport, low temperature vending cabinets and household refrigerators are needed.

The moisture that accounts for most of the weight of the food has been removed, so it is lightweight and easy to transport. Rehydration is rapid and easy to eat. Ultimately it will bring you high added value and economic benefits. This series of equipment is suitable for a wide range of applications, freeze-drying: Vegetables: edible mushrooms, garlic slices, shallots, onions, green beans, peas, cucumbers, sweet corn, carrot slices, spinach, asparagus. Mountain wild vegetables and so on. Aquatic products and meat: shellfish, shrimp, fish sticks, beef, pork, chicken, mutton and so on. Seasoning: garlic powder, ginger powder, onion powder, tomatoes, pepper. Instant drinks: coffee, tea, soup, soy milk, milk, etc. Convenience food: children's food, snack food, military camp food. Fresh Chinese herbal medicine: ginseng, pilose antler, Sanqi, etc.

Freeze Dryer Designed and manufactured based on GMP requirement, ATLAS technology&structure, adopts a solid construction with a small occupied area and convenient installation and transportation.

Its operation can be controlled by hand, automatic program or computer. It will be more reliable if being equipped with the unit.

Machine Parts

Name: Compressor

Brand: bIZER

Original: Germany

The Refrigerating System of vacuum freeze dryer adopts the weni-closed compressor imported from USA. The key components such as the medium refrigerator, solenoid valve, expansion valve and oil distributor are also purchased from world-famous companies. Therefore, an ideal refrigerating temperature can be ensured and the reliability product in china.

Main Features

Name: Ammonia System

Brand: SINOPED

Original: China

Ammonia separator system is a unique part of TJL series plants.It consists of ammonia separator,ammonia pumps,vapor trap vessel,pipes and vavles etc.Low temperature ammonia in the separator can keep the vacuum of the cabin for 3 to 5 minutes when temporary trouble occurs.

Machine Parts.

Name: Heating System

Brand: SINOPED

Original: China

Heat supply system-made up of water heating tank,plate exchanger,pneumatic control valves,pumps and pipes, liquid-level indicator, temperature sensors and assembly heating plates,is a forced circulation under the auto-control pressure of gas nitrogen.

Main Features.

Name: Pilot Freeze Drying machine

Brand: SINOPED

Original: China

pilot model.

Size from 0.5m2 to 200 m2

EU configuration standard

Sino Pharmaceutical Equipment Development (Liaoyang) Co., Ltd. (SINOPED) is a professional manufacturer and supplier of pharmaceutical and chemical machinery and equipment in China. We belong to SINOPEC International Group.

We have a well-experienced team to manufacture pharmaceutical machinery and equipments and a professional design institute. With rich experiences in pharmaceutical machinery and equipment field and numbers of professional engineers, we have designed and developed many types of machinery and equipments including clean room project, soft-gel production line, glass-lined reactor, fermentor, centrifuge, granulator, mixer, dryers, pulverizer, tablet press, soft and hard blister packing machine, capsule filling machines, cartoner and rollers, etc.

Due to our good credit and service, , we have made great achievements in the past years. We have established long-term business relations with many customers and some of our overseas customers have appointed us to be their purchase agency in China. Our products are exported to many countries & areas, such as Korea, India, Indonesia, Pakistan, Thailand

In SINOPED you can get your desired goods with the best prices and good quality. Welcome your enquiries from all over the world.