Низкая цена Высококачественная машина для производства пластин из флексополимера флексографического

- Категория: Pre-Press Equipment >>>

- Поставщик: Suzhou,Flying,Man,Assembly,Automation,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.65 $* | 0.44 $* |

| Aug-17-2025 | 0.3 $* | 0.11 $* |

| Jul-17-2025 | 0.73 $* | 0.25 $* |

| Jun-17-2025 | 0.80 $* | 0.22 $* |

| May-17-2025 | 0.12 $* | 0.53 $* |

| Apr-17-2025 | 0.94 $* | 0.0 $* |

| Mar-17-2025 | 0.58 $* | 0.17 $* |

| Feb-17-2025 | 0.19 $* | 0.39 $* |

| Jan-17-2025 | 0.81 $* | 0.54 $* |

Характеристики

Video Description

Products Description

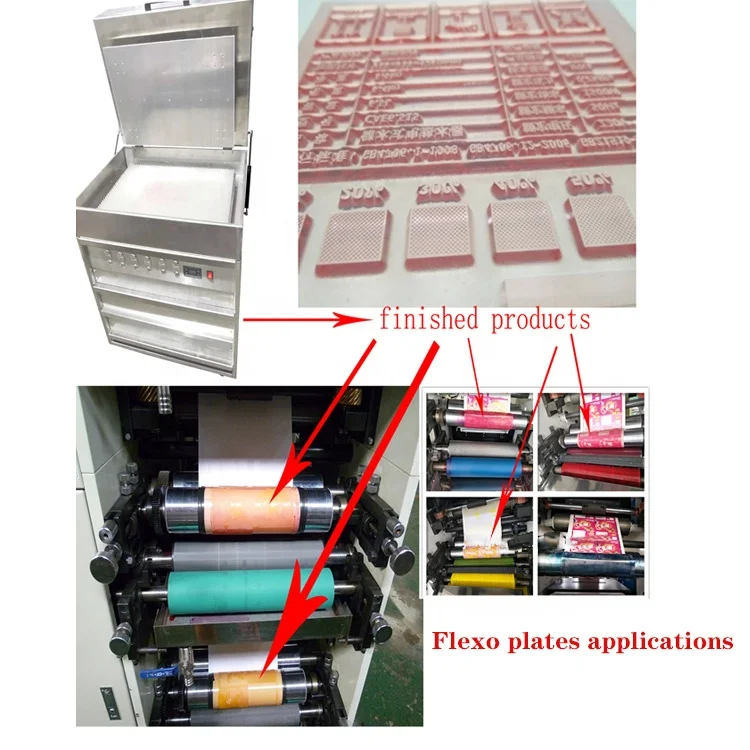

Flying Man Photoploymer Flexo Resin Plate Making Machine is used together with printing machine, the printing pattern is clear, used high quality brush, uniform brushing force, easy to use and operate.

The whole body of Flexo Resin Plate Making Machine uses stainless steel, the maintenance cost of electrical equipment is low.

Product Paramenters

Specification for Photoploymer Flexo Resin Plate Making Machine for flexo printer

Model | Product size (mm) | Power (w) | Plate area (mm) | Number of exposure tubes (root) | Number of unglued lamps (root) |

FRPM3242 | 620x450x940 | 1040 | ≤420*310 | 9 (15W) | 5 (15W) |

FRPM4060 | 780x520x940 | 1500 | ≤590*420 | 11 (20W) | 6 (20W) |

FRPM6080 | 970x730x1040 | 1820 | ≤790*590 | 21 (20W) | 12 (20W) |

FRPM6090 | 1090x740x1040 | 2050 | ≤890*590 | 16 (20W) | 9 (20W) |

FRPM90120 | 1400x1040x1040 | 2500 | ≤1190*890 | 24 (30W) | 14 (30W) |

FRPM100120 | 1400x1140x1030 | 2600 | ≤1190*990 | 27 (30W) | 15 (30W) |

Performance Feature

- The whole body of Flexo Resin Plate Making Machine was made of stainless steel, featuring in durability and won’t get rusty.

- Use professional exposure tubes and UV tubes.

- Using high - quality semi - transparent frosted film as vacuum film.

- Adopt digital temperature sensor, high sensitivity of temperature measurement.

- Adopt high precision timer, precise control plate making time.

- With high-quality wool brush, washing plate strength is uniform, easy button operation, low maintenance cost of accessories.

Step 1:Back exposure 60 seconds (according to the actual plate instructions, and light power to adjust).

Step 2:Put the photographic plate, fix the position of the photographic plate and the plate below, open the vacuum pump, and apply the vacuum film to vacuum.

Step 3:Push the sliding door back and turn on the burst light (the time is adjusted according to the requirements of the plate manual and the light power).

Step 4:Put the double-sided tape on the back of the exposed plate, then stick it on the aluminum plate, cover the cover, and click the brush to start (120 seconds).

Step 5:Put the washed plate into the oven for dehumidification.

Step 6:The flood dry plate in UV adhesive layer to remove the adhesive, and then put the exposure layer for curing, and then can be used.

Product Application

Flying Man Photoploymer Flexo Resin Plate Making Machine for printing on flexible packaging ,paper bags, labels, high-value folding cartons, beverage bag, carton pre-printing, etc.

Whole Service

Technical Service

- Free sample testing and video for your reference.

- Technical support: Professional engineers’ team to help you design a whole-set product line to get highest profit with lowest cost and offer you technical support any time.

Training service

Free training in our factory available before delivering machines.

Engineers available to service machinery overseas. Overseas service center in Vietnam available.

Engineers available to service machinery overseas. Overseas service center in Vietnam available.

After Sales Service

- Every customer can get one piece of English operation manual , a total working video for machines ,details on every button function ,normal notice when operation.

- One-year warranty, whole life technical support.

- One-year warranty, whole life technical support.

- 24 hours technical support, we will do our best to help our customers solve problems.

- We offer not only the products, but also the solutions. Plenty of cooperated professional supplier for mold or other necessary equipment make it possible for us to offer our customers big convenience to complete their production line in high quality with low cost in a short time.

PACKAGE

We use exporting standard packing. First to wrap PE film around the machine, then packed by plywood case to ensure the package enough safe and strong. It’s easy for forklift to upload and download and safety transportation. We also can pack the machine according to customers special requirement.

SHIPPING

Usually we suggest customers choose ocean shipping to ship machinery, or air transport for small machine or urgent order. We also supply shipping service with our cooperation shipping forwarder to help customers to deliver the machinery in first time.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

FAQ

Q: Are you a factory or trading company?

A: We are a factory and manufacturer.

Q: Where is your factory located in? How can I visit there?

A: Our factory is located in Kunshan city, Jiangsu province, and our detailed address is: No.1008, Xiangshi Road, Bacheng Town, Kunshan City, JiangSu Province, China.

It’s only 40 minutes' away from Shanghai Hongqiao airport by car, and 18 minutes' away from Shanghai railway station by high-speed rail. The traffic is very convenient.

Q: what are your main products?

A: Our main products are high speed precision die cutting machines, cutting machines, slitting machines, laminating machines and printing machines.

Q: Which industries can use your machines ?

A: All industries need to cut (include full cutting and kiss-cutting), slit, laminate, die cut raw materials can use our machines. Mainly used for material before and after cutting and/or printing.

Q: How to control the quality in your factory?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials to the finished products. Our factory has obtained CE Certification.

Q: If there are no machines available from your list, could we customize non-standard machines from you?

A: Yes, we have our own professional design engineers, and can customize products according to your requirement. 30% of our current customer need customization on their machines.

Q: What's the trade term?

A: EXW, FOB, CFR, CIF or DDU are all workable based on customer’s requirement.

Your question will be highly appreciated.

A: We are a factory and manufacturer.

Q: Where is your factory located in? How can I visit there?

A: Our factory is located in Kunshan city, Jiangsu province, and our detailed address is: No.1008, Xiangshi Road, Bacheng Town, Kunshan City, JiangSu Province, China.

It’s only 40 minutes' away from Shanghai Hongqiao airport by car, and 18 minutes' away from Shanghai railway station by high-speed rail. The traffic is very convenient.

Q: what are your main products?

A: Our main products are high speed precision die cutting machines, cutting machines, slitting machines, laminating machines and printing machines.

Q: Which industries can use your machines ?

A: All industries need to cut (include full cutting and kiss-cutting), slit, laminate, die cut raw materials can use our machines. Mainly used for material before and after cutting and/or printing.

Q: How to control the quality in your factory?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials to the finished products. Our factory has obtained CE Certification.

Q: If there are no machines available from your list, could we customize non-standard machines from you?

A: Yes, we have our own professional design engineers, and can customize products according to your requirement. 30% of our current customer need customization on their machines.

Q: What's the trade term?

A: EXW, FOB, CFR, CIF or DDU are all workable based on customer’s requirement.

Your question will be highly appreciated.