Новинка! Двигатель шпинделя с водяным охлаждением 1 5 кВт ER11 d65мм в комплекте инвертором QL алюминиевым кронштейном 65 мм насосом 75

- Категория: Machine Tool Spindle >>>

- Поставщик: Suzhou,Penny,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 250.84 $* | 263.74 $* |

| Aug-18-2025 | 248.52 $* | 260.25 $* |

| Jul-18-2025 | 208.21 $* | 218.95 $* |

| Jun-18-2025 | 244.55 $* | 256.72 $* |

| May-18-2025 | 212.86 $* | 223.50 $* |

| Apr-18-2025 | 239.33 $* | 251.51 $* |

| Mar-18-2025 | 237.47 $* | 249.22 $* |

| Feb-18-2025 | 235.83 $* | 247.2 $* |

| Jan-18-2025 | 233.82 $* | 245.31 $* |

Характеристики

Product Description

1 & 1.5kw ER11 water cooled spindle 65x209mm 4 bearings

1 & 1.5kw QL inverter/VFD

1 & 65mm spindle bracket/holder

1 & 75w water pump & 5m tubes

1 & 1.5kw QL inverter/VFD

1 & 65mm spindle bracket/holder

1 & 75w water pump & 5m tubes

Size: 65 x 209mm (Middle body diameter:65mm;Length:209mm)

Speed Ways: Through 3-phase output inverter and adjust the inverter frequency to change the spindle speed.

Cooling: Water cooling

Power Interface: Optional H17-4 pins waterproof air plug. The air plug marked "1 ","2"," 3"," 4", "1 ","2 ","3" were connected to

inverter (U, V, W), 4 connected inverter ground. (Pay attention! our spindle "4" connecting to GND,promised personal safety!!)

Power: 1.5kw (1HP=0.735kw)

Voltage: 220vAC (If you need 110v/380v spindle ,please leave message to us,thank you)

Frequency: 0-400Hz

Speed: 0-24000rpm

Runout Off: 0.01mm

Fully sealed P4 angular contact bearings

Bearing Type: 2×7002C P4 DT & 2 ×7000C P4 DT

4 pcs angular contact bearings

Water Cooling ER11 collet chunk

Grease Lubrication

Main Application: Engrave for wood,bamboo,normal PCB,PVC,PMMA,plastic,duotone board(ABS)and etc nonmetal, also can engrave on

gold,silver,copper, aluminium,Pb etc soft metal surface working.

(Please pay more attention, this is wood working spindle, only can used for wood working and aluminum working,please don't use it

for steel. If you need steel working,please check the metal spindle,thank you!)

Speed Ways: Through 3-phase output inverter and adjust the inverter frequency to change the spindle speed.

Cooling: Water cooling

Power Interface: Optional H17-4 pins waterproof air plug. The air plug marked "1 ","2"," 3"," 4", "1 ","2 ","3" were connected to

inverter (U, V, W), 4 connected inverter ground. (Pay attention! our spindle "4" connecting to GND,promised personal safety!!)

Power: 1.5kw (1HP=0.735kw)

Voltage: 220vAC (If you need 110v/380v spindle ,please leave message to us,thank you)

Frequency: 0-400Hz

Speed: 0-24000rpm

Runout Off: 0.01mm

Fully sealed P4 angular contact bearings

Bearing Type: 2×7002C P4 DT & 2 ×7000C P4 DT

4 pcs angular contact bearings

Water Cooling ER11 collet chunk

Grease Lubrication

Main Application: Engrave for wood,bamboo,normal PCB,PVC,PMMA,plastic,duotone board(ABS)and etc nonmetal, also can engrave on

gold,silver,copper, aluminium,Pb etc soft metal surface working.

(Please pay more attention, this is wood working spindle, only can used for wood working and aluminum working,please don't use it

for steel. If you need steel working,please check the metal spindle,thank you!)

P4 angular contact bearings ,2×7002 P4 DT & 2×7000 P4 DT,increase spindle life Longer length make the torque bigger,more

powerful. Carefull assembly make the spindle more precisional. Precision 0.01mm.Coaxial degree less than 0.0025mm Shipment

within 4 days,promise the delivery time.

Many customers asked for D=65mm 1.5kw spindle, then our engineer produced this spindle, this is really 1.5kw D=65mm water cooled

spindle, you can place the order without doubt.

powerful. Carefull assembly make the spindle more precisional. Precision 0.01mm.Coaxial degree less than 0.0025mm Shipment

within 4 days,promise the delivery time.

Many customers asked for D=65mm 1.5kw spindle, then our engineer produced this spindle, this is really 1.5kw D=65mm water cooled

spindle, you can place the order without doubt.

We are the spindle manufacturer,we offer only best quality and best price to you.

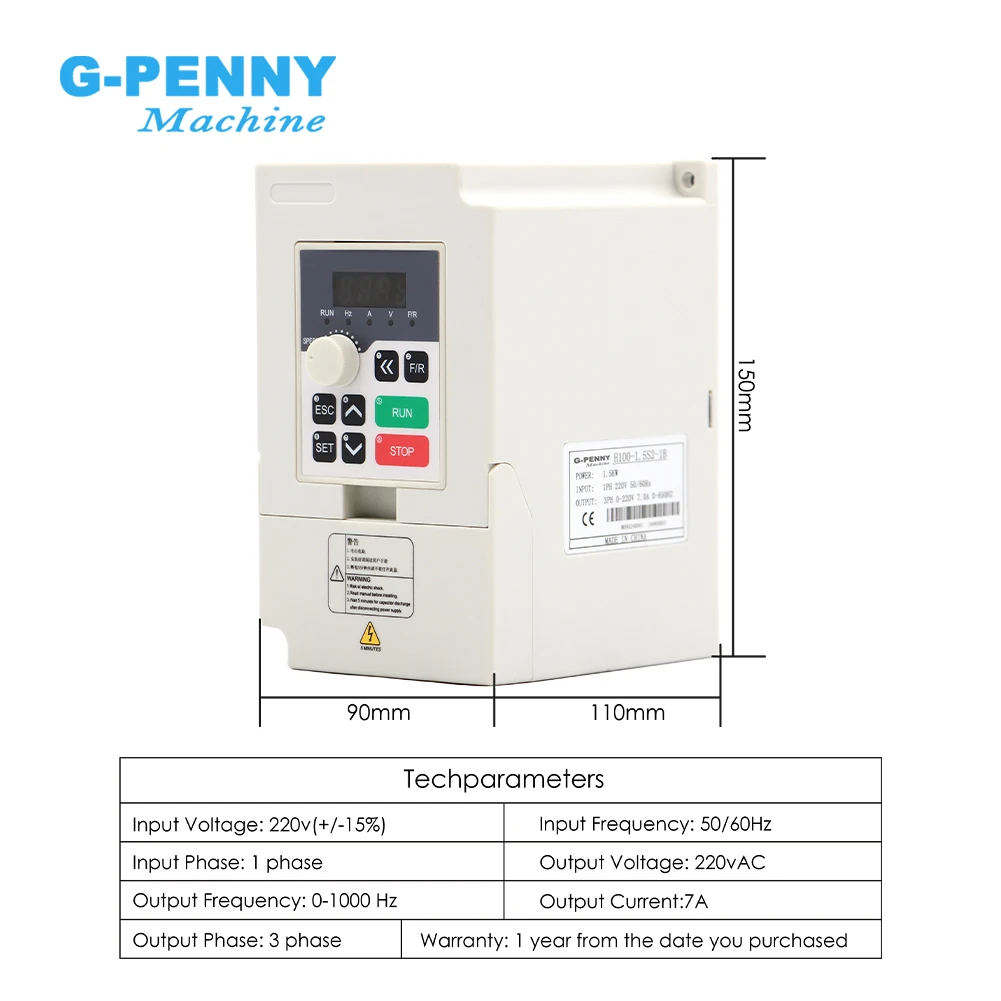

QL 220v 1.5kw inverter

Input Voltage: 220V(+/-15%)

Output Voltage: 220VAC

Input Frequency: 50-60 Hz

Output Frequency: 0-1000 Hz

Input Phase: 1 phase

Output Phase: 3 phase

Warranty: 1 year from the date you purchased

Input Voltage: 220V(+/-15%)

Output Voltage: 220VAC

Input Frequency: 50-60 Hz

Output Frequency: 0-1000 Hz

Input Phase: 1 phase

Output Phase: 3 phase

Warranty: 1 year from the date you purchased

DO NOT set up the inverter by yourself if you don't know how to, or it will make both the spindle and inverter burn easily.

Please contact us, we have manuals, videos and pictures to help you.

Please contact us, we have manuals, videos and pictures to help you.

◆Two speed control modes: no PG vector control (SVC), V/F control

◆ No PG vector control (SVC): starting torque 0.5Hz up to 150%

◆ 8-stage simple PLC function, multi-speed control and PID control

◆ Support multiple frequency settings: digital setting, analog setting, PID setting, RS485 communication setting

◆ I/O terminals can be freely programmed to combine multiple working modes according to user needs.

◆ With jump frequency control function, it can effectively suppress mechanical resonance and make the system more stable and

reliable.

◆ With instantaneous power-down retention function, it can avoid the impact of production due to instantaneous power failure

◆ With over torque and under torque detection

◆ Automatic voltage adjustment function to effectively solve the low frequency oscillation problem of high power motor

◆ Provide a variety of fault protection functions: over-current, over-voltage, under-voltage, over-heat, overload, lack of equal

real-time monitoring and protection to ensure safe operation.

◆ No PG vector control (SVC): starting torque 0.5Hz up to 150%

◆ 8-stage simple PLC function, multi-speed control and PID control

◆ Support multiple frequency settings: digital setting, analog setting, PID setting, RS485 communication setting

◆ I/O terminals can be freely programmed to combine multiple working modes according to user needs.

◆ With jump frequency control function, it can effectively suppress mechanical resonance and make the system more stable and

reliable.

◆ With instantaneous power-down retention function, it can avoid the impact of production due to instantaneous power failure

◆ With over torque and under torque detection

◆ Automatic voltage adjustment function to effectively solve the low frequency oscillation problem of high power motor

◆ Provide a variety of fault protection functions: over-current, over-voltage, under-voltage, over-heat, overload, lack of equal

real-time monitoring and protection to ensure safe operation.

Application

winding machine,mixer, extruder,slitter, winder,compressor, ventilator,pump,grinder, conveyor,elevator, centrifuger and other

speed control machines.

winding machine,mixer, extruder,slitter, winder,compressor, ventilator,pump,grinder, conveyor,elevator, centrifuger and other

speed control machines.

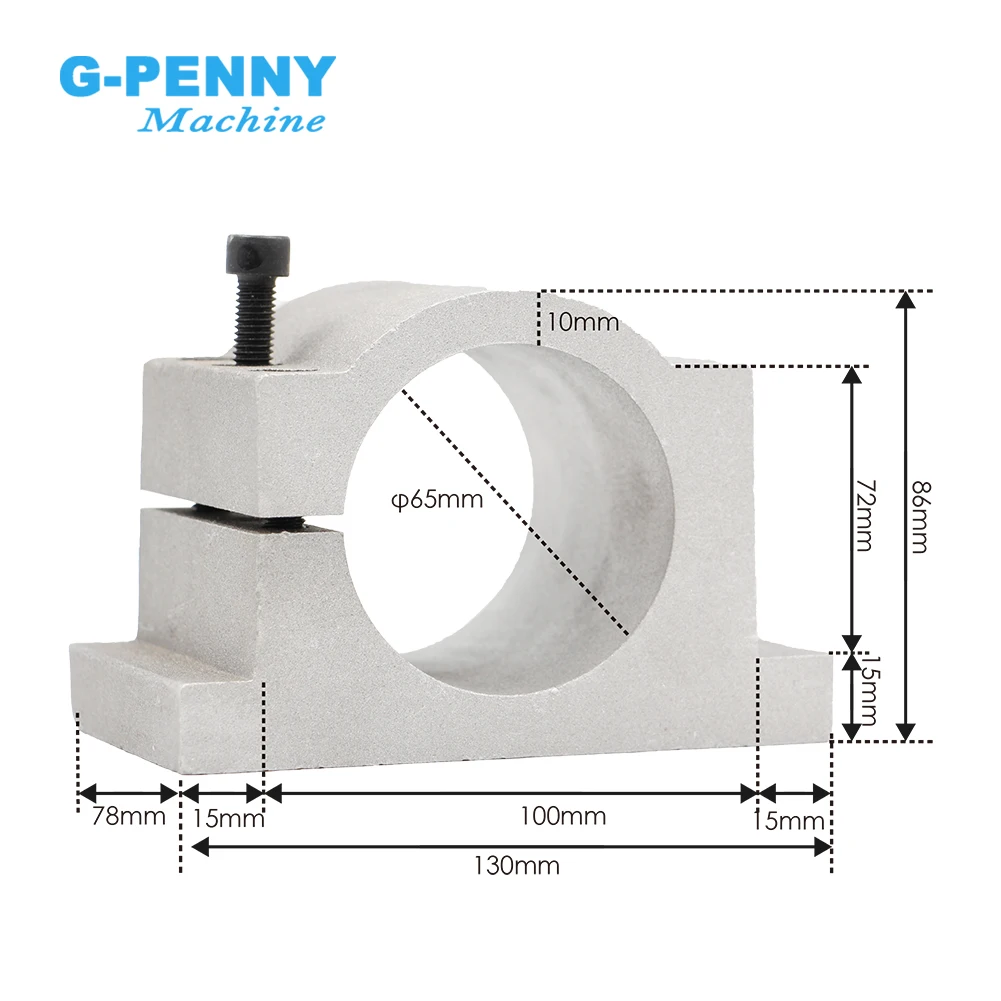

Diameter:65mm

Material: Cast Aluminium

Features

1. Compared with the aluminium profile fixture,the accuracy is much higher , and it is hard to deform.

2. Inner wall is very smooth, outer walls is sandblasted, relatively fine uniform, but not very smooth.

3. Cast aluminium fixture is much heavier than aluminium profile fixture.

Product Description

Cast aluminium fixture is high quality aluminium which is casting with a special manufacturing process ,compared with ordinary

aluminium ,This product has toughness, strong shock resistance, high hardness and strong antioxidant activity.

Usage

Cast aluminium fixture is mainly used for fixation of ancillary products, thereby ensuring the verticality of balancing and

ancillary products, ancillary products to improve running accuracy, reduce noise, reduce the accumulated error.

Material: Cast Aluminium

Features

1. Compared with the aluminium profile fixture,the accuracy is much higher , and it is hard to deform.

2. Inner wall is very smooth, outer walls is sandblasted, relatively fine uniform, but not very smooth.

3. Cast aluminium fixture is much heavier than aluminium profile fixture.

Product Description

Cast aluminium fixture is high quality aluminium which is casting with a special manufacturing process ,compared with ordinary

aluminium ,This product has toughness, strong shock resistance, high hardness and strong antioxidant activity.

Usage

Cast aluminium fixture is mainly used for fixation of ancillary products, thereby ensuring the verticality of balancing and

ancillary products, ancillary products to improve running accuracy, reduce noise, reduce the accumulated error.

Max Head: 3.2 m;

Power: 75w;

Maximum flow: 3200L / H

Plug Cord Length: 1.4m

Voltage: 220V;

Frequency: 50 HZ

Outlet size: 4 and 6 mm;

Dimensions: 145 * 110 * 90 mm

Advantage

High Life/Large Flow Rate/Highly Durable/Excellent Insulation/Can cool the machine quickly/Good quality and long life/Large

inventory/Big strong power

Features

1. The shell is made of high quality plastic, which is anti corrosive and high durable.

2. Pumps have excellent insulation thanks to the motor bearing completely sealed.

3. Pumps combione pumping, filtered,oxygen and fountains in one.

Note

1. Must be used in the water.

2. Must cut off the electricity once the product works improperly and must maintain it after lifting it from the water.

Power: 75w;

Maximum flow: 3200L / H

Plug Cord Length: 1.4m

Voltage: 220V;

Frequency: 50 HZ

Outlet size: 4 and 6 mm;

Dimensions: 145 * 110 * 90 mm

Advantage

High Life/Large Flow Rate/Highly Durable/Excellent Insulation/Can cool the machine quickly/Good quality and long life/Large

inventory/Big strong power

Features

1. The shell is made of high quality plastic, which is anti corrosive and high durable.

2. Pumps have excellent insulation thanks to the motor bearing completely sealed.

3. Pumps combione pumping, filtered,oxygen and fountains in one.

Note

1. Must be used in the water.

2. Must cut off the electricity once the product works improperly and must maintain it after lifting it from the water.

* Spindle working environment temperature is usually -10 ~ 40 .

* Before installing the first electric spindle axis head turned by hand, should feel flexible, non-blocking phenomenon.

* Before installing the first electric spindle axis head turned by hand, should feel flexible, non-blocking phenomenon.

* Spindle in the preservation and transportation, high-speed grease inside the bearing state will change, customers should be running at low speed for 30 minutes. 3000 rpm and then follow the poor increase, run 20 minutes each. Spindle and the inverter should be working together. The inverter's specifications and parameter settings need match spindles parameter.(Because of high-speed grease inside the bearing state will change,when you get the spindle, maybe the noise sounds not normal.Please run it 30 minutes or even more, the noise will be normal.)

* Connect the inverter spindle, three-phase inverter power cord should be soldered in the plug 1 (U), 2 (V), 3 (W) feet, 4 feet for the ground. After the power is turned on, to observe whether the spindle rotation axis indicates the direction consistent. If inconsistency should be immediately shut down, replace the inverter and spindle connected two wires of three-phase power supply.

* During normal operation, air-cooled spindle often encounter the phenomenon of heat, always check whether the air-cooled spindle housing and duct clogging dust.If clogging dust, to promptly clean up. If you do not clean up, it is easily to make the spindle burned.

* Every day before using the spindle must be running at low speed for 15-20 minutes. Clamping the cutters to spindle, collet nuts, collets, cutters must be clean enough. Shank inserted into the collet must be greater than 15mm.

* Connect the inverter spindle, three-phase inverter power cord should be soldered in the plug 1 (U), 2 (V), 3 (W) feet, 4 feet for the ground. After the power is turned on, to observe whether the spindle rotation axis indicates the direction consistent. If inconsistency should be immediately shut down, replace the inverter and spindle connected two wires of three-phase power supply.

* During normal operation, air-cooled spindle often encounter the phenomenon of heat, always check whether the air-cooled spindle housing and duct clogging dust.If clogging dust, to promptly clean up. If you do not clean up, it is easily to make the spindle burned.

* Every day before using the spindle must be running at low speed for 15-20 minutes. Clamping the cutters to spindle, collet nuts, collets, cutters must be clean enough. Shank inserted into the collet must be greater than 15mm.

* Water cooled spindle MUST be used with water pump. Otherwise the spindle will soon broken.

* AC spindle motor MUST use with inverter. The power of inverter need equal or bigger than the spindle power. Before using,please set up the inverter parameters suitable for spindle. Otherwise the spindle and inverter will broken at once.

* When you use the spindle,the noise is not same as always,please STOP the spindle at once. You may need to replace the spindle bearings.

* AC spindle motor MUST use with inverter. The power of inverter need equal or bigger than the spindle power. Before using,please set up the inverter parameters suitable for spindle. Otherwise the spindle and inverter will broken at once.

* When you use the spindle,the noise is not same as always,please STOP the spindle at once. You may need to replace the spindle bearings.

1. Cooling in different ways: water-cooled spindle motor is the use of the water cycle to cool the heat generated after the high-speed rotating spindle, spindle motor with fan-cooled approach to cooling.

2. Noise: Water-cooled spindle motor is basically no noise, but the air-cooled spindle motor is very loud.

3. Life aspects: Water-cooled spindle motor pay attention to maintenance, frequently changes the water or the use of industrial water coolers, air-cooled spindle fan mainly by the wind blowing the heat transferred to the heat sink, so as to achieve the cooling effect.

4.If you need use for metal ,hard wood,granite,stone,you can choose metal spindle.Metal spindle much better than wood spindle.

2. Noise: Water-cooled spindle motor is basically no noise, but the air-cooled spindle motor is very loud.

3. Life aspects: Water-cooled spindle motor pay attention to maintenance, frequently changes the water or the use of industrial water coolers, air-cooled spindle fan mainly by the wind blowing the heat transferred to the heat sink, so as to achieve the cooling effect.

4.If you need use for metal ,hard wood,granite,stone,you can choose metal spindle.Metal spindle much better than wood spindle.

* We will 100% guarantee security to the hands of the guests.

* Spindle from the production - assembly - test, and finally the perfect packaging .

* Spindle from the production - assembly - test, and finally the perfect packaging .

Shipping Cost:

Our products are sold worldwide.

If you need many items in the same time, please contact us in advance to confirm shipping cost.

Payment:

We accept paypal credit, bank transfer, western union etc.

Payment must be made within 7days calendar days of the auction end time.

Problem and Feedback:

PLEASE DON'T leave any negative feedback before you contact us.

We are honest and helpful supplier , we will try our best to solve problems with you.

Your satisfaction is very important for our store, so please contact us before you want to leave a negative feedback.

Thanks very much in advance.

Refund:

If you are NOT SATISFIED with our package like the products is damage, please do not sign it and contact us immediately.

If it is possible, please take some photos or make a small video about it. It will help us to solve the problems.

Note:

We can produce the product according to our customer's design.

If you need something is very special, please contact us about it.

We are willing to help you about it.

Our products are sold worldwide.

If you need many items in the same time, please contact us in advance to confirm shipping cost.

Payment:

We accept paypal credit, bank transfer, western union etc.

Payment must be made within 7days calendar days of the auction end time.

Problem and Feedback:

PLEASE DON'T leave any negative feedback before you contact us.

We are honest and helpful supplier , we will try our best to solve problems with you.

Your satisfaction is very important for our store, so please contact us before you want to leave a negative feedback.

Thanks very much in advance.

Refund:

If you are NOT SATISFIED with our package like the products is damage, please do not sign it and contact us immediately.

If it is possible, please take some photos or make a small video about it. It will help us to solve the problems.

Note:

We can produce the product according to our customer's design.

If you need something is very special, please contact us about it.

We are willing to help you about it.

Похожие товары

Хорошая цена 1,8 кВт 1000 Гц 60000 об/мин ATC шпиндель CNC машина шпиндель

US $900.00-$950.00

90 мм BT30 ременной приводной шпиндель фрезерный станок шпиндель

US $399.00-$950.00