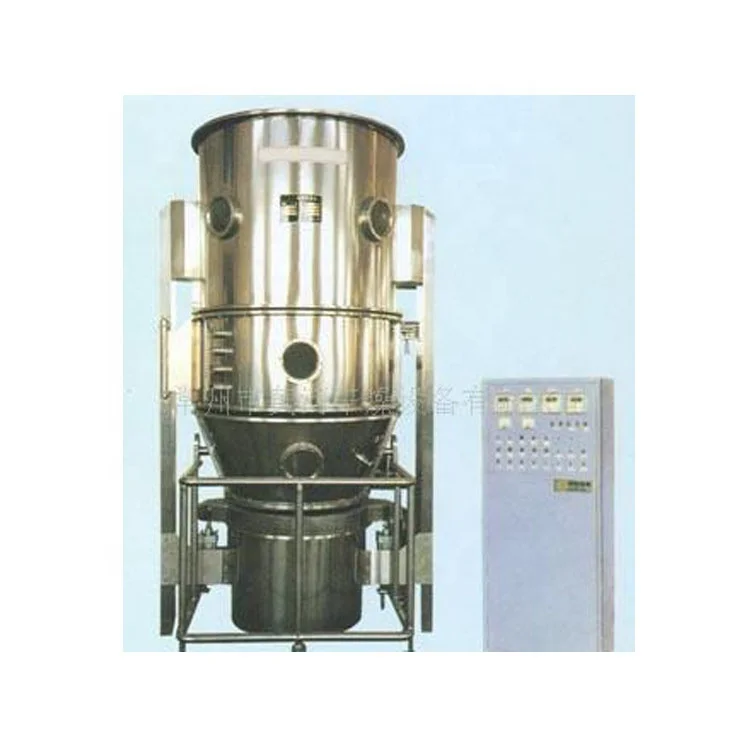

Высокое качество FG модель гранул Вертикальная сушилка с псевдоожиженным слоем оборудование для сушки в псевдоожиженном

- Категория: Fluid Bed Drying Equipment >>>

- Поставщик: Changzhou,Haomai,Drying,Engineering,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 14280.62 $* | 14994.96 $* |

| Aug-18-2025 | 14160.76 $* | 14868.37 $* |

| Jul-18-2025 | 11880.22 $* | 12474.21 $* |

| Jun-18-2025 | 13920.54 $* | 14616.79 $* |

| May-18-2025 | 12120.56 $* | 12726.3 $* |

| Apr-18-2025 | 13680.96 $* | 14364.57 $* |

| Mar-18-2025 | 13560.26 $* | 14238.30 $* |

| Feb-18-2025 | 13440.69 $* | 14112.39 $* |

| Jan-18-2025 | 13320.17 $* | 13986.50 $* |

Характеристики

High quality FG model granule vertical fluid bed dryer fluid bed drying equipment

Specialists:

1. The fluidized bed has a circular structure to avoid dead ends;

2. The equipment has a wide processing range and can adapt to different materials, and the drying effect is remarkable;

3. It has a wider fluidization range than the traditional horizontal XF boiling dryer;

4, can handle some particles that are too wet, sticky or widely distributed in the particle size range;

5. The equipment stirring device in the bed avoids the agglomeration formed by the agglomeration and drying process of the wet materials;

6, can handle materials with low temperature, but high final moisture requirements

7. The whole equipment is easy to operate, easy to disassemble, easy to clean, and meets the requirements of “GMP”;

8. The feeding method adopts the automatic suction mode to reduce the trouble of manual feeding;

9. The material is discharged by auger, which is convenient for operation and reduces the artificial strength.

10. Compared with the traditional two-stage CPE drying, the round bottom stirring fluidized bed can meet the requirements as long as one equipment:

A. Save the floor area;

B. Saving investment cost and manual operation cost of equipment;

C. Reduced exhaust emissions

container of raw material | dim. | mm | 300 | 400 | 700 | 1000 | 1200 | 1400 | |

volume | L | 12 | 22 | 100 | 220 | 420 | 670 | ||

production capacity | Min | kg/batch | 1.5 | 4 | 15 | 30 | 80 | 100 | |

Max | kg/batch | 4 | 6 | 36 | 72 | 140 | 240 | ||

consume of steam | kg/batch | 12 | 23 | 70 | 140 | 211 | 282 | ||

amount of compressed air | m3/min | 0.3 | 0.3 | 0.3 | 0.6 | 0.6 | 0.9 | ||

power of fan | kw | 2.2 | 4 | 5.5 | 11 | 18.5 | 22 | ||

temperature | °c | Adjustable from ambient to 120 | |||||||

collection rate | % | >99 | |||||||

ti | mi | e of operation | min | 15~30(depends on material) | |||||

content of final moisture | % | ~0.2( depends on material) | |||||||

noise | dB | 75 | |||||||

height of main machine | mm | 2100 | 2300 | 2500 | 3000 | 3300 | 3800 | ||