Пищевой rtv силиконовый каучук для формы торта и

- Категория: Silicone Rubber >>>

- Поставщик: Dongguan,Guochuang,Organic,Silicone,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.62 $* | 0.92 $* |

| Aug-19-2025 | 0.84 $* | 0.53 $* |

| Jul-19-2025 | 0.49 $* | 0.79 $* |

| Jun-19-2025 | 0.53 $* | 0.35 $* |

| May-19-2025 | 0.70 $* | 0.82 $* |

| Apr-19-2025 | 0.93 $* | 0.87 $* |

| Mar-19-2025 | 0.81 $* | 0.75 $* |

| Feb-19-2025 | 0.61 $* | 0.79 $* |

| Jan-19-2025 | 0.41 $* | 0.84 $* |

Характеристики

1.Description of food grade rtv silicone rubber for cake candy mould

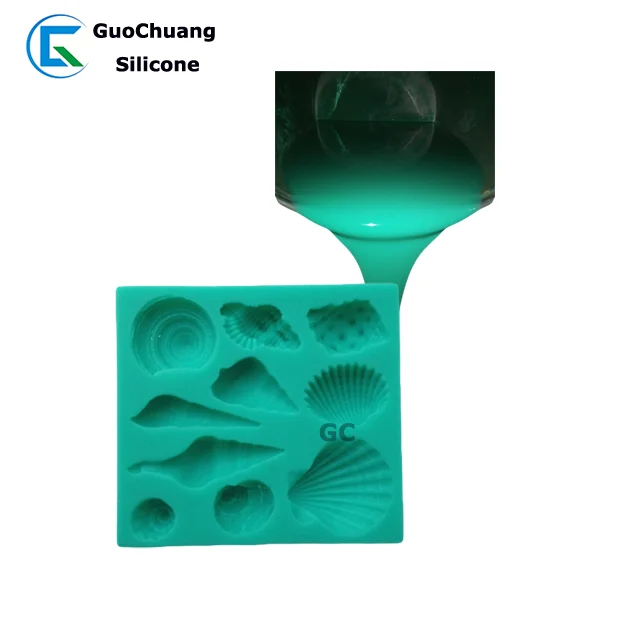

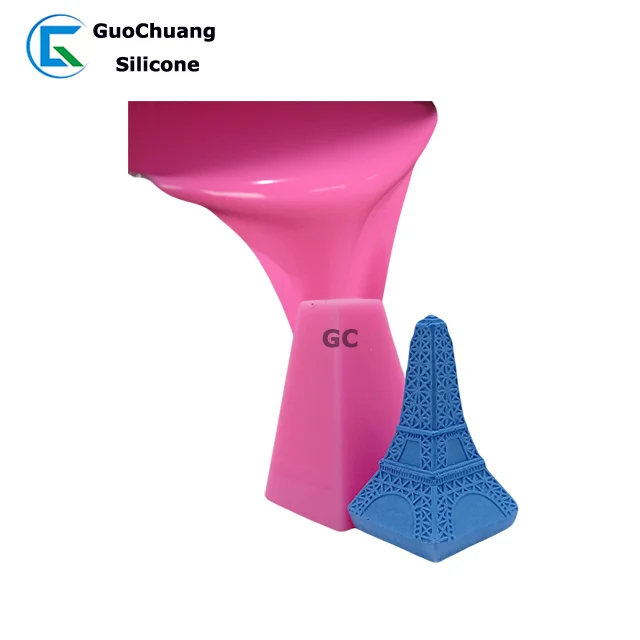

SP-815 silicone is addition cure silicone rubber with food grade for chocolate mold. The silicone rubber will be cured under room temperature and can be cured fastly by heating, It’s two-components food grade liquid silicone rubber , the mixing ratio is 1:1 . It has an exceptional fluidity and good operability.Especially ,the platinum cure silicone rubber has a lower shrinkage,higher temperature resistance and it is food grade.SP-815 is suitable to make the mold for the product with small and moderate size.

2.Characteristics of food grade rtv silicone rubber for cake candy mould

*An exceptional fluidity and good operability

*Good tensile strength and tear strength

*Food grade silicone rubber

*High temperature resistance

*Good flexibility

*No smell ,non-toxic

*Long shelf-time &lifetime

*Lower shrinkage

3.Application of food grade rtv silicone rubber for cake candy mould

SP-815 silicone rubber is food grade silicone rubber, it is suitable for mold making . it is suitable to make silicone chocolate mold ,silicone cake mold ,silicone fondant mold , sugar mold ,3D candy mold , etc...It is also suitable for tyre mold ,shoe mold ,gypsum casting mold,resin craft mold,plaster products,bronze casting,concrete stone, cement products,GRC casting ,garden casting ,vacuum molding ,gasket,etc…It is also suitable for silicone soap mold,silicone candle mold,....Especially, G815 is also suitable for making artificial limbs,such as emulational foot,hands,etc….

4.Datesheet of food grade rtv silicone rubber for cake candy mould

Item No. | Appearance | Hardness (shore A°) | Viscosity (CPS) | Tensile-strength( kgf /cm2 ) | Tear-strength (kgf /cm2 ) | Elongation-break(%) | Mixing ratio | operation time (25 ℃ ) | Curing time( 25 ℃) | shrinkage |

SP815 | tranlucent | 15±2 | 5000±1000 | ≥45 | ≥20 | ≥400 | 1:1 | 20-30 mins | 2~3 h | ≤0.1% |

1. Place a plastic container on a small scale, making sure to zero out the weight on the scale. Note: use a container that, during rise under vacuum in Step 5, will allow for material to expand to 4-5 times its resting volume.

2. Pour catalyst into the plastic container, noting weight of material poured.

3. In the same container, pour an equal weight of base on top of the catalyst (e.g., 100 grams of catalyst and 100 grams base). Note: within a 5% weight variance, the end result is not altered.

4. With a clean, dry mixing spatula, mix energetically until the color of the product is homogeneous. Note: working time begins at this step. Mixing should take no longer than 1-2 minutes.

5. Place container under vacuum and vacuum until material bubbles and rises. Release vacuum and repeat until bubbles are removed. Vacuuming should take no longer than 3-4 minutes.

6. From a height of approximately 30 cm, pour the mixed silicone into the mold frame. Maintain the pouring stream in the same spot so as to minimize introduction of air bubbles into the mold.

7. Allow the mold to sit, undisturbed, for at least 4 hours to ensure the silicone is fully cured.

8. Remove the mold from the frame.

9. Cut around the pattern carefully to release it from the silicone rubber mold.

Notice

The surfaces with which the material comes in contact must be perfectly clean, free of grease and dry.

Close the bottles after use so as not to confuse the cap of the catalyst with that of the base when re-sealing.

Be aware of possible cross-contamination; it’s highly recommended to use only dedicated gear when processing poly-addition RTV2 silicone rubber (including degassing devices).

Be aware that contact with certain material can inhibit the curing of the RTV2 poly-addition silicone rubber. Common contaminants to be avoided include:

-Natural or synthetic rubber, vulcanized with sulphur derivatives.

-Poly-condensation RTV catalyzed with metallic salts.

-PVC stabilizing agents.

-Amine cured epoxies.

-Sulphur, tin and amines derivatives.

-In case of doubt, carry out a small test by pouring the mixture onto a small area of the object.

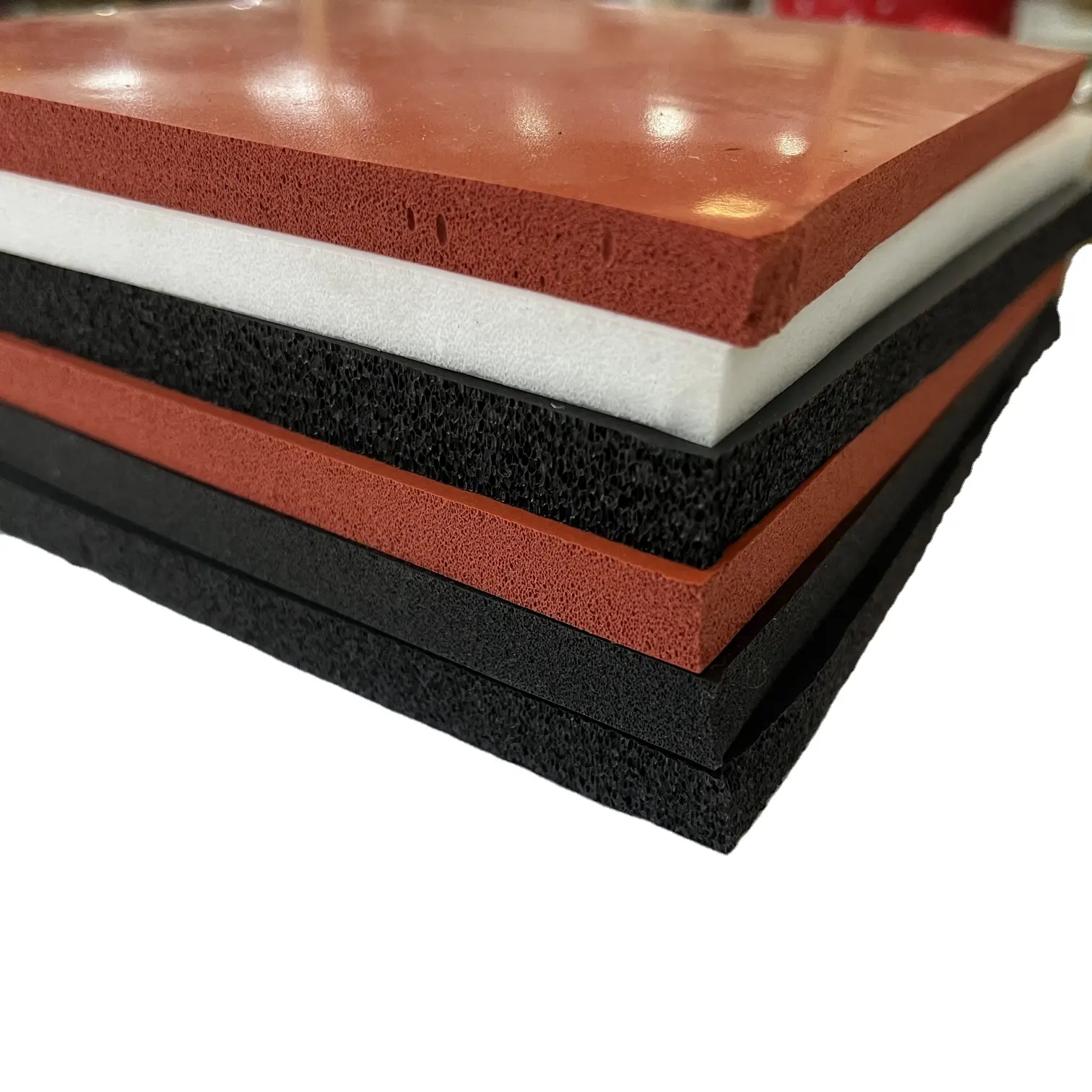

Various color is available

Packing:

20KG/drum vacuum packing for part A + 20KG/drum vacuum packing for part B

25KG/drum vacuum packing for part A + 25KG/drum vacuum packing for part B

200KG/drum packing for part A +200KG/drum packing for part B

(1) With us your money in safe, your business in safe.

(2) Free sample for testing.

(3) Competitive price.

(4) Strict Q/C (quality of control) management system.

(5) Enough production capacity and timely delivery.

(6) We support customized package and product.

(7) Prompt shipment with professional documents.

(8) Offering professional technical support.

(9) We can make confidentiality agreement with our customs.

(10) We will be here whenever you need.