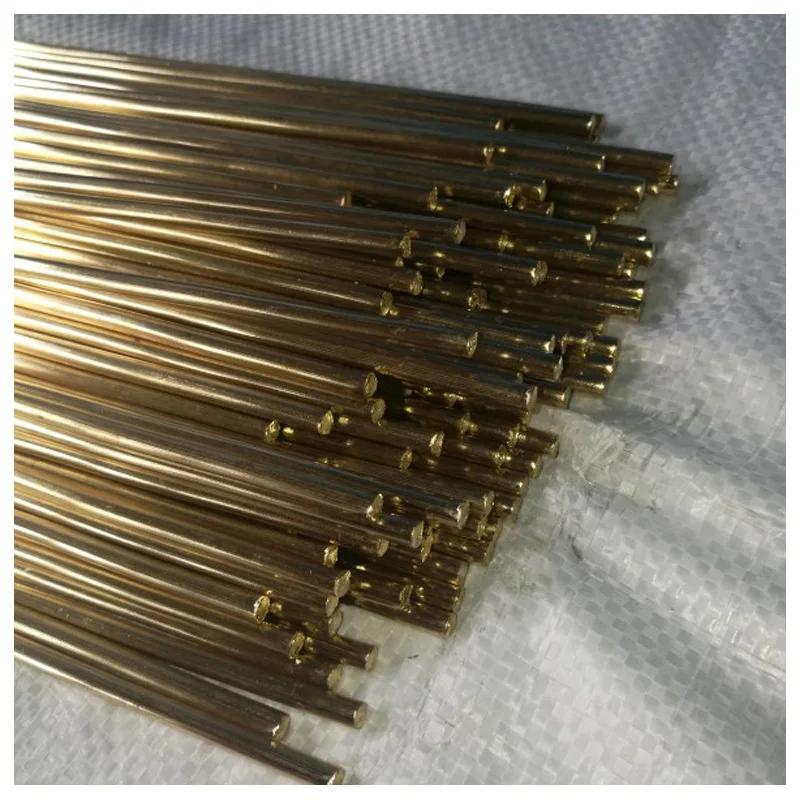

Construction site Brass welding rods Strong solder joints HS221 tin brass

- Категория: Welding Rods >>>

- Поставщик: Wenling,Import,&,Export,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 11.63 $* | 11.40 $* |

| Jul-19-2025 | 9.48 $* | 9.87 $* |

| Jun-19-2025 | 11.86 $* | 11.94 $* |

| May-19-2025 | 11.0 $* | 11.27 $* |

| Apr-19-2025 | 9.72 $* | 9.59 $* |

| Mar-19-2025 | 11.52 $* | 11.55 $* |

| Feb-19-2025 | 11.79 $* | 11.34 $* |

| Jan-19-2025 | 11.79 $* | 11.53 $* |

Характеристики

Construction site Brass welding rods, Strong solder joints HS221 tin brass welding rod

Email: sales03(a)smarter-tool.com Phone/whatsapp/wechat:8613777623169

HS221 is a special brass welding wire with a small amount of tin and silicon. The melting point is about 890 degrees Celsius. Tin can improve the fluidity, strength and corrosion resistance of the welding wire, while silicon can effectively control the evaporation of zinc, eliminate pores and obtain satisfactory mechanical properties.

Brass oxyacetylene gas welding and carbon arc welding are used as filler materials. It is also widely used in brazing copper, steel, copper-nickel alloy, gray cast iron and inlaid carbide tools, etc., and has a wide range of uses.

Precautions:

1. The groove of the weldment and the surface of the welding wire must be carefully cleaned before welding.

2. Before welding, it is generally preheated to 400-500 degrees Celsius before welding. The copper gas welding solvent must be used as the solvent when welding.

3. The welding flame should be a neutral flame or a slight oxidizing flame. The temperature during welding should be appropriately reduced, the welding speed should be increased, and the residence time of the molten pool at high temperatures should be minimized to reduce the evaporation and oxidation of zinc.

Copper Brazing Alloys (Copper Brazing Alloys)

Copper-zinc alloy solder for copper-based products

Equivalent to National Mark | Chemical Compositions | Material temperature | Advantages and usage | |||||||

Cu | Zn | Sn | Si | Mn | Fe | Melting point | Recommended welding temperature | |||

HS221 | BCu60ZnSn-R | 59~61 | margin | 0.8~1.2 | 0.15~0.35 | / | / | 890~905 | 910~954 | Brazing of copper and copper alloys, steel, cast iron, etc., flame brazing, furnace welding, induction welding can be used |

HS226 | BCu58ZnFe-R | 57~59 | margin | 0.7~1.0 | 0.05~0.15 | / | 0.35~1.2. | 865~890 | 910~960 | Brazing of copper and copper alloys, steel, cast iron, etc., flame brazing, furnace welding, induction welding can be used |

HL105 | BCu58MnZn | 57~59 | margin | / | / | 3.7~4.3 | 0.15 | 880~910 | 910~960 | Good wettability, good strength and plasticity, suitable for brazing hard alloy tools and saw blades |

HPCu-F | / | margin | Copper-based amorphous B, P, Si minor elements (thickness specification: 0.035*20) | 560~640 | 700~750 | The lowest melting point, used for welding precision instruments, circuits and components, contacts, heat exchangers, etc. | ||||

HPNi-7 | BNi-2 | Nickel-based amorphous B, P, Si minor elements (thickness specification: 0.035*55) | 960~990 | 1000~1100 | Used for welding high-temperature alloy and stainless steel parts (such as aviation parts, automobile and ship parts, cooking utensils, medical equipment, etc.).

| |||||

We are established in 1997's as a science and technology-oriented enterprise,

engaging in designing, manufacturing and marketing in various of welding

equipement and electromechanical equipment.

The factory is located in Wenling city, China and covers an area of 60,000 square

and with 3.5 million USD registered capital.

There are 400 employees in our company, including 40 engineers and technical

staff in R&D, 20 salesman and 30 professional and senior managerial staff.

Our products mainly exported to South&North America, Central&Southeast

Asia, Europe , Australia.

We welcome customers all over the world to cooperate with us.

Our oath is supporting our long-term partners to win a better market.

Looking forward to establishing business relationships with you in the

near future.

1. Inquiry response:Your inquires will be replied in 24 hours.

2. Samples are available in 7-10 days. The cost and freight will be paid by the

buyer but will be refunded in your first order.

3. OEM is welcomed: We can design the machine both inside structure and

outlooking and color box.

4. On time shipment.

5. 1 year warranty period.During this guarantee period, we will provide spare parts

(not include consumable spare parts) without any charge in case of quality

discrepancy caused by us.

If the malfunctions are caused by your incorrect operations, we will provide the spare

parts at cost price.

6. If you need help after you receive the machine , please call us or

email us to get more detailed technical assistance . We will reply you

within 24 hours.