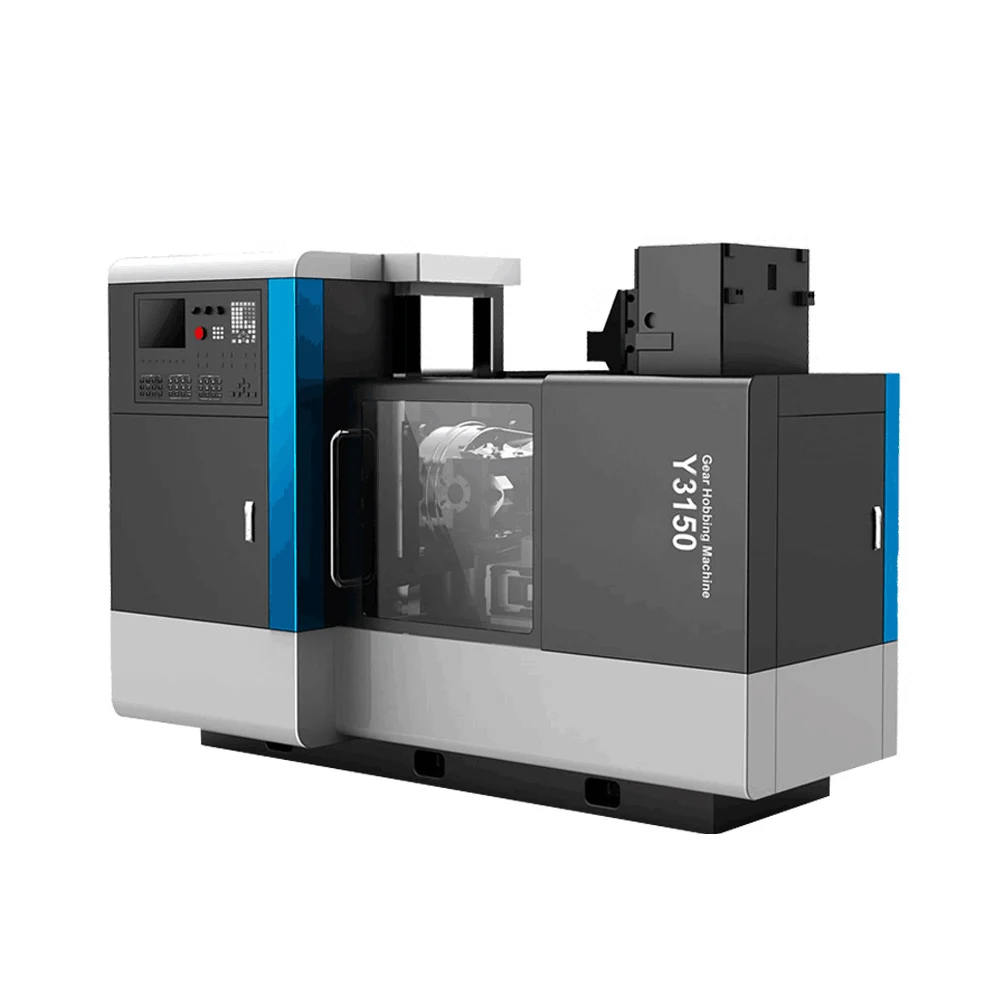

Y31250 зубчатый фрезерный станок от производителя вертикальный

- Категория: >>>

- Поставщик: Dalian,Dahui,Machine,Tool,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 96152.63 $* | 100960.35 $* |

| Aug-16-2025 | 95344.0 $* | 100111.97 $* |

| Jul-16-2025 | 79992.4 $* | 83992.94 $* |

| Jun-16-2025 | 93728.39 $* | 98414.38 $* |

| May-16-2025 | 81608.51 $* | 85688.17 $* |

| Apr-16-2025 | 92112.0 $* | 96718.93 $* |

| Mar-16-2025 | 91304.48 $* | 95869.5 $* |

| Feb-16-2025 | 90496.92 $* | 95021.61 $* |

| Jan-16-2025 | 89688.79 $* | 94172.92 $* |

Характеристики

Product Description

Y3150E general type hobbing machine, gear hob used to generating method hobbing cylindrical spur gear, helical gear and spline, sprocket, etc. Machine could also adopt the method of manual radial feed to processing ordinary worm gear. According to the user's requirements, special parts, using tangential feed hobbing worm gear.

SPECIFICATION

Middle-Duty Size Gear Hobbing Machine | ||||||||||||

Item | Unit | Y31125 | Y31160 | Y31180 | Y31200 | Y31250 | ||||||

Max machining diameter | mm | 1000/1250 | 1300/1600 | 1800 | 2000 | 2500 | ||||||

(without column) | ||||||||||||

Max modulus | mm | 16/18 | 16/20 | 24 | 24 | 16/20 | ||||||

Max width of teeth | mm | 450 | 450 | 1100 | 1100 | 1100 | ||||||

Max hob diameter/length | mm | 245/220 | 280/320 | 325/360 | 325/360 | 260/300 | ||||||

Diameter of Worktable | mm | 950 | 1100 | 1450 | 1650 | 1380 | ||||||

Spindle Speed/steps | rpm | 16-125/7 | 19-124/7 | 10-92 | 10-92 | 16-100 | ||||||

Max hob shift axial | mm | 100 | 100 | 140 | 140 | 140 | ||||||

Main Motor | kw/rpm | 15/1500 | 15/1500 | 22/1500 | 22/1500 | 14/1440 | ||||||

Worktable bore diameter | mm | 200 | 260 | 260 | 260 | 275 | ||||||

Max hob swivelling angle | degree | ±60 | ±60 | ±45 | ±45 | ±45 | ||||||

Diameter of hob arbor | mm | 27,32,40,50 | 32,40,50 | 32,40,50,60,80 | 32,40,50,60,80 | 32,40,50,60,80 | ||||||

Detailed Images

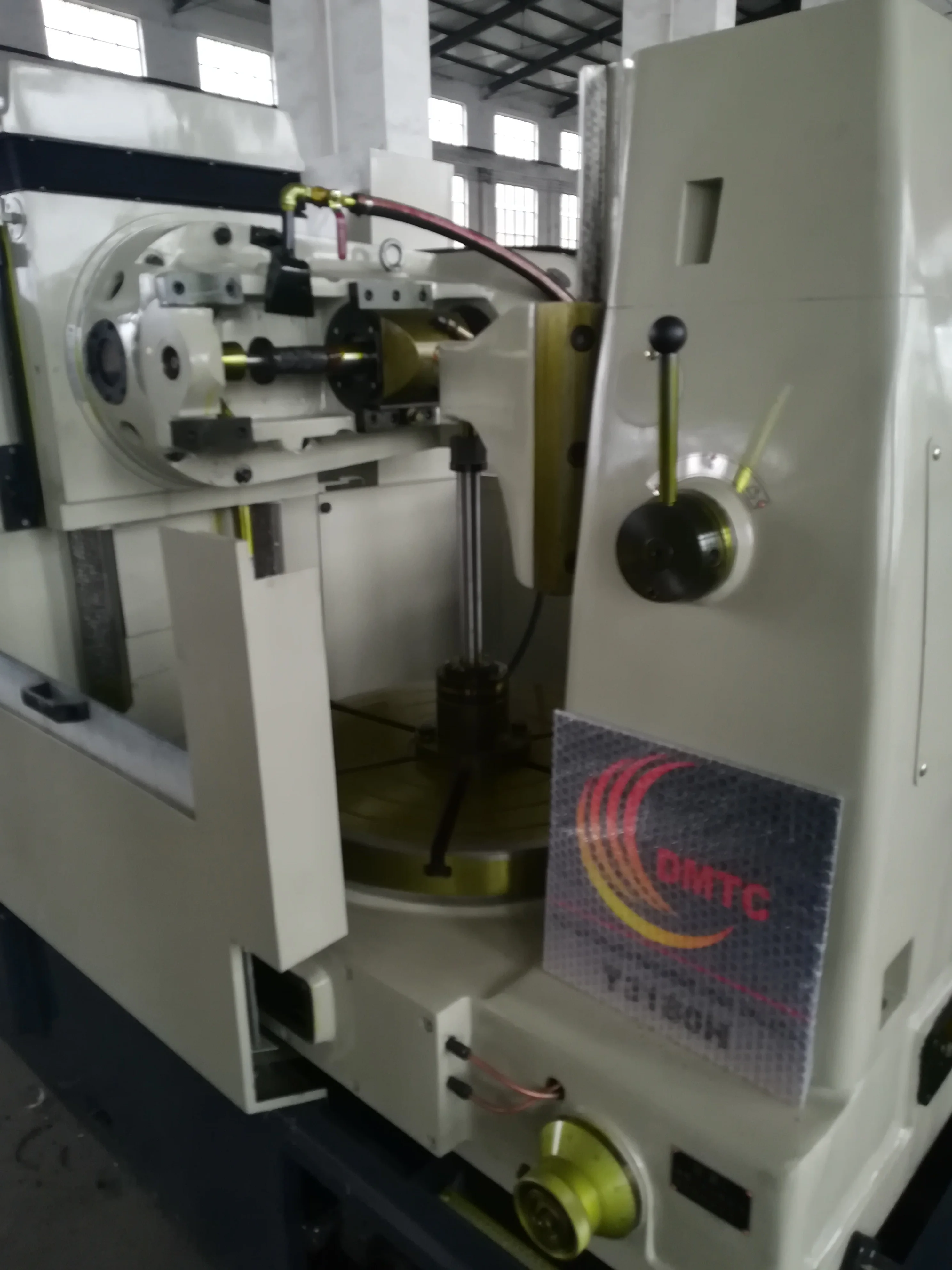

Worktable/Workbench

Base on workbench institutions by the workbench, the workbench, spindle unit.Workbench with: stop, inching and variable speed function.The workbench to withstand vertical load.Machine tool under the condition of environment temperature 0 to 40 degrees can work normally.

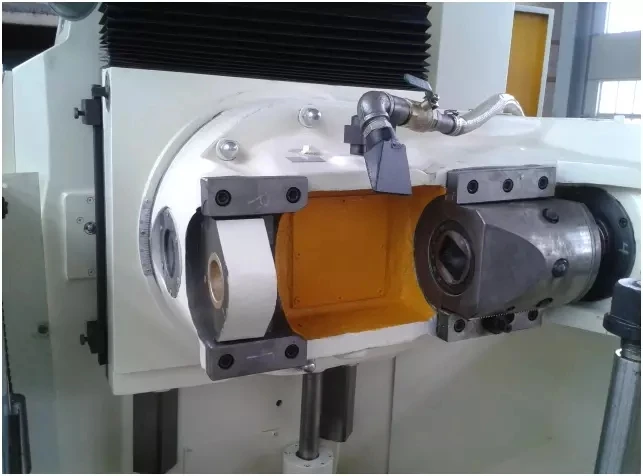

Hob carriage:

The hob holder is used to support the hob main shaft and drive the hob mounted on the main shaft to make vertical feed motion. The internal bearing adopts domestic famous or imported bearings with long life.

Change Gear:

The gear is selected from domestic high-quality suppliers, such as SMTCL or other well-known manufacturers. In addition, the combination of different hanging wheels will achieve the purpose of rolling out different gear forms.

Hand Wheel:

Operating the handle, different handles can achieve different speeds, the specific speed is related to the size of the machine.

Hydraulic lubrication system

stable and reliable product quality, strong commonality.

Rear Column

When loading and unloading workpieces, turret rotation is to rely on manual.

Electrical and Operation

the normal operation of the machine tool and the safety of the operator.

Machines Picture

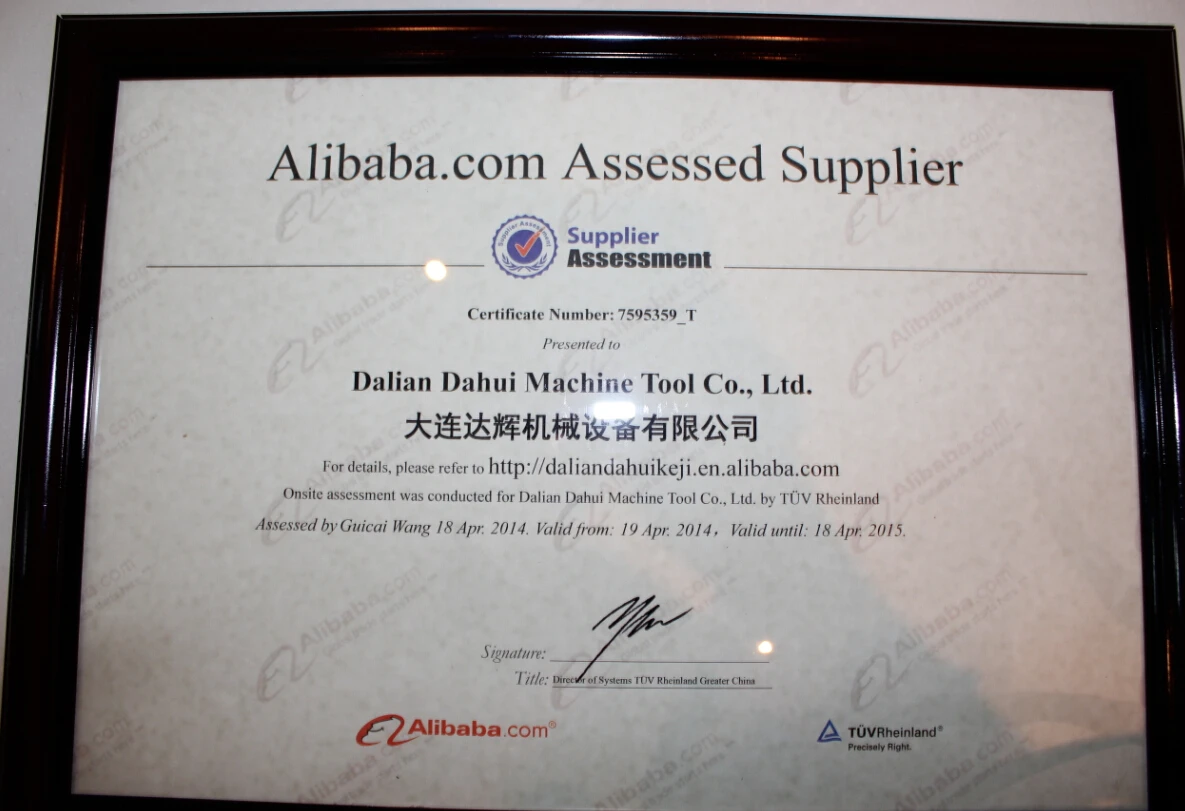

Certificate

Packing&Shipping

Company Introduction

Dalian Dahui Machinery Equipment Co., Ltd. is a professional manufacturer and trading company engaged in the manufacturing and export of various types of machine tools such like: CNC Lathe Machine, Vertical Lathe Machine, Horizontal Lathe Machine, Boring Machine, Machining Center and their accessories. Since its establishment in 2009, its products have been exported to more than 20 countries and regions, including Italy, Sweden, Turkey, Russia, Saudi Arabia, the United Arab Emirates, Australia, and Mexico. With reliable product quality and meticulous after-sales service, it has won customers' trust and praise.

Our Services & Strength

Our service:

DMTC provides 7x24-hour online pre-sale service, engineer follow-up order service, and logistics operation service. With years of understanding of various markets, engineers who have toured various countries for a long time provide installation services. In addition, we can help customers successfully complete a series of services such as import clearance, thereby reducing customer costs in all aspects.

Our advantage:

Advantage 1: CE, ISO certification.

Advantage 2: Full production tracking.

Advantage 3: Engineers stationed in the factory guarantee the highest quality.

Advantage 4: More suppliers as alternatives, guarantee your lowest price.

Advantage 5: Sales staff who have been in the business for more than 10 years, answer your pre-sales / after-sales questions.

Advantage 6: Engineers traveling around the world to ensure after-sales service.

Advantage 7: OEM, ODM production, to meet customer needs in all aspects.

Advantage 8: 5% -10% deposit, giving you the greatest trust and the least pressure on funds.

Advantage 9: Low MOQ for only 1 unit.

Advantage 10: For small equipment (such as boring machines) guaranteed in-stock all year round.

DMTC provides 7x24-hour online pre-sale service, engineer follow-up order service, and logistics operation service. With years of understanding of various markets, engineers who have toured various countries for a long time provide installation services. In addition, we can help customers successfully complete a series of services such as import clearance, thereby reducing customer costs in all aspects.

Our advantage:

Advantage 1: CE, ISO certification.

Advantage 2: Full production tracking.

Advantage 3: Engineers stationed in the factory guarantee the highest quality.

Advantage 4: More suppliers as alternatives, guarantee your lowest price.

Advantage 5: Sales staff who have been in the business for more than 10 years, answer your pre-sales / after-sales questions.

Advantage 6: Engineers traveling around the world to ensure after-sales service.

Advantage 7: OEM, ODM production, to meet customer needs in all aspects.

Advantage 8: 5% -10% deposit, giving you the greatest trust and the least pressure on funds.

Advantage 9: Low MOQ for only 1 unit.

Advantage 10: For small equipment (such as boring machines) guaranteed in-stock all year round.

FAQ

Похожие товары

Yk3180 стабильный точность Mitsubishi чпу зубофрезерный станок

US $50000-$80000

SJBC630 Ленточная пила для разделки труб

US $10606-$11000

Y3150E Y3180 зубчатая машина для продажи

US $15000-$15200