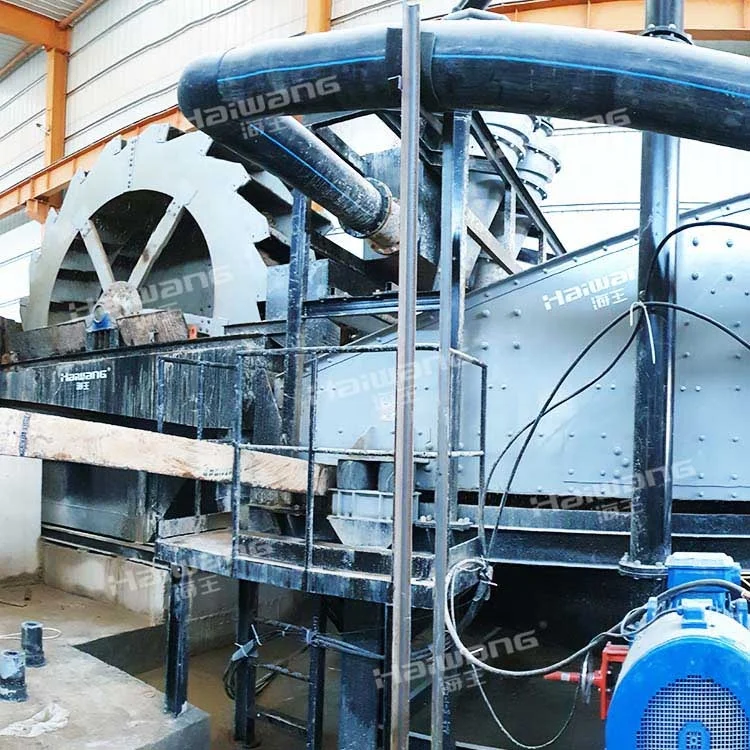

sand washer for sale with capacity of 30 tph applied

- Категория: Sand Washer >>>

- Поставщик: Weihai,Haiwang,Hydrocyclone,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 1333.3 $* | 1400.56 $* |

| Aug-16-2025 | 1322.19 $* | 1388.2 $* |

| Jul-16-2025 | 1109.64 $* | 1164.29 $* |

| Jun-16-2025 | 1299.68 $* | 1364.57 $* |

| May-16-2025 | 1131.79 $* | 1188.79 $* |

| Apr-16-2025 | 1277.2 $* | 1341.82 $* |

| Mar-16-2025 | 1266.19 $* | 1329.48 $* |

| Feb-16-2025 | 1254.42 $* | 1317.8 $* |

| Jan-16-2025 | 1243.84 $* | 1305.65 $* |

Характеристики

Product Description

Wheel bucket sands washing machine portable for sands recovery from China supplier

With the acceleration of urbanization in China, the amount of sand aggregate and quality demand are also increasing. Haiwang, in view of the current mechanism sand production process, focuses on the efficient recovery of medium and fine sand and develops the equipment such as efficient wheel washing sand machine, fine sand recovery cyclone, sand washing and desliming cyclone, fine sand recovery integrated machine, and sand washing & fine sand recovery integrated machine, which assists the upgrading of sand washing & fine sand recovery technology.Specification | Capacity (t/h) | Water flow (m³/h) | Recovery size (μm) | Reference power (Kw) |

XS2615 | 80-100 | 100-200 | >250 | 5.5 |

XS4210 | 100-150 | 150-300 | >250 | 5.5 |

XS3015 | 150-200 | 150-400 | >250 | 7.5 |

XS4215 | 200-250 | 200-400 | >250 | 11.0 |

XS4215-II | 250-300 | 200-500 | >250 | 15.0 |

Key equipment I:

High efficiency wheel washing machine.

Haiwang high efficiency wheel washing machine combines sand washing wheel bucket with tank classifier to solve the problem of low recovery rate of fine sand in traditional wheel bucket sand washing machine. The silt content in sand washing products of Haiwang high efficiency wheel washing machine is generally < 3%, and the recovery rate of sand over 0.15 mm is > 90%.

Haiwang high efficiency wheel washing machine combines sand washing wheel bucket with tank classifier to solve the problem of low recovery rate of fine sand in traditional wheel bucket sand washing machine. The silt content in sand washing products of Haiwang high efficiency wheel washing machine is generally < 3%, and the recovery rate of sand over 0.15 mm is > 90%.

.

Key Equipment II: According to the different lithology and silt content of raw materials, Haiwang developed the fine sand efficient recovery cyclone and sand washing desliming cyclone. For thd recovery condition with less silt and mainly secondary stone powder, the use of fine sand efficient recovery cyclone can ensure that the recovery rate of + 0.074 mm fine sand reaches more than 95%; for sand washing wastewater generated by raw material with high silt content, the use of sand washing desliming cyclone can ensure the effective removal of fine silt in the raw material, and the silt content in the final fine sand product can be controlled below 5%. | ||

Key Equipment III:

Fine Sand Recovery Integrated Machine

Haiwang Fine Sand Recovery Integrated Machine integrates the two processes of cyclone fine sand recovery and linear vibrating screen product de-watering in one equipment. Relying on Haiwang efficient cyclone separation technology, it can realize the recovery rate of + 0.075 mm fine sand in the feeding materials by more than 95%, and the moisture content in fine sand products is < 20%.

Size Information

Specifications and Technical Parameters of Hydrocyclone

Specification | Diameter (mm) | Inlet Pressure (MPa) | Capacity (m³) | Cut Size (μm) |

FX10 | 10 | 0.1-0.6 | 0.05-0.1 | 1-5 |

FX25 | 25 | 0.1-0.6 | 0.3-0.1 | 5-20 |

FX50 | 50 | 0.1-0.4 | 2-5 | 5-40 |

FX75 | 75 | 0.1-0.4 | 5-10 | 10-40 |

FX100 | 100 | 0.1-0.3 | 8-20 | 20-50 |

FX150 | 150 | 0.08-0.3 | 14-35 | 20-74 |

FX200 | 200 | 0.06-0.3 | 25-40 | 40-100 |

FX250 | 250 | 0.06-0.3 | 40-80 | 40-100 |

FX300 | 300 | 0.06-0.2 | 45-90 | 50-150 |

FX350 | 350 | 0.06-0.2 | 70-160 | 50-150 |

FX400 | 400 | 0.06-0.2 | 100-170 | 74-150 |

FX500 | 500 | 0.04-0.2 | 140-240 | 74-200 |

FX610 | 610 | 0.04-0.15 | 200-300 | 74-200 |

FX660 | 660 | 0.04-0.15 | 260-450 | 74-220 |

FX710 | 710 | 0.04-0.15 | 500-900 | 74-350 |

FX840 | 840 | 0.04-0.15 | 500-900 | 74-350 |

Packing&Shipping

Packed by non-fumigation ply-wood case

After completing the factory acceptance test, the equipment will be dismantled into big assembled pieces. We’ll use the non-fumigation plywood case for full packing, and arrange delivery to the project site. All the packing cases are marked with weight, and set lifting point in the required position. Document like the case list, detailed packing list, storage instructions etc will be provided. There will also be markings indicate the oversized and overweight pieces.

Our after-sale Service In China we have near 100 engineers serving at site over 200 days annually to deliver thoughtful services to guarantee production technical specification meet clients’ requirement. After many years’ research and practice, they have extensive experiences and know-how. In recent years, we focus more and more on international market and dispatch excellent engineers to serve abroad quite often. They help customers with optimum mineral processing solution, improve customer’s efficiency and reduce costs. | ||

Company Introduction

Haiwang is the “National Torch Plan Key High-Tech Enterprise” , “New High-tech Enterprise of Shandong Province” , “Single-Item Champion Enterprise in the Manufacturing Field of Shandong Province” , “Shandong Engineering Technology Research Center” and “Shandong Academician Self-Owned Brand Enterprise of Shandong Province” and has established services in design, consultation and technical support for clients. Besides, Workstation” etc. seven innovation platforms. We have the professional R&D team of more than 100 persons, to provide the professional rights, including 8 patents for invention, 1 patent of “National Technology Haiwang also has more than 60 patents of independent intellectual property Invention Award” , 5 patents of “National Key New Products” , with the honor in the industry of drawing up 3 industrial standards as the technical forerunner and leader.

Our Strength

Haiwang has its own manufacturing bases, which cover an area of more than 150,000 square meters.

The annual capacity is over 20,000 sets of different sizes of cyclones, more than 5,000 sets of vibrating screens and separators etc.

The spare part warehouse with an area of more than 20,000 square meters;

The EU CE certification, Quality Management System ISO9001, Environmental Management

Systems ISO14001, Occupational Health & Safety Management

System OHSAS18001 and GOST Russian authentication.

System OHSAS18001 and GOST Russian authentication.

The world largest phosphorite mine: Saudi Arabia Ma’aden Phosphorite Mine

The world largest copper mine per single

line: Peru Toromocho Copper Mine

line: Peru Toromocho Copper Mine

The Asia largest iron mine: Sijiaying Iron Mine of Hebei Iron & Steel Group

The Asia largest nickel mine: Jinchuan Nickel Concentrator

The Asia largest molybdenum mine: Baihualing Mine.

There are also many other different types of successful projects for your reference and welcome to contact us.

FAQ

HAIWANG REFERENCES:

We have taken 70% domestic market share in mineral processing field and successfully applied in over 30 countries for different types of ores. The world largest phosphorite mine: Saudi Arabia Ma’aden Phosphorite Mine The world largest copper mine per single line: Peru Toromocho Copper Mine The Asia largest iron mine: Sijiaying Iron Mine of Hebei Iron & Steel Group The Asia largest nickel mine: Jinchuan Nickel Concentrator The Asia largest molybdenum mine: Baihualing Mine. There are also many other different types of successful projects for your reference and welcome to contact us.

Why We Choose Haiwang?

1.Haiwang owns multifarious patent structure and advanced technology at abroad and domestic: ①According to the feeding method, feed structure could be divided into the involute feeding, the volute pre-classifying feeding, spiral feeding etc.

②According to cone structure, it could be divided into flat bottom structure, multi-cone structure, the cone angle gradient structure, etc.

③According to the overflow way, it could be divided into the air conditioning and energy saving overflow cap, thick wall overflow pipe and other design.

2. Personalized structure design is available.

We can produce suitable hydrocyclone according to client’s demand or working condition. Various wear-resisting material: High alumina ceramic, rubber, polyurethane, ceramic composite materials. How is the quality of your products?(mining equipment/machine)

Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery. Service and Payment Terms We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

③According to the overflow way, it could be divided into the air conditioning and energy saving overflow cap, thick wall overflow pipe and other design.

2. Personalized structure design is available.

We can produce suitable hydrocyclone according to client’s demand or working condition. Various wear-resisting material: High alumina ceramic, rubber, polyurethane, ceramic composite materials. How is the quality of your products?(mining equipment/machine)

Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery. Service and Payment Terms We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

RECOMMENDED PRODUCTS Vibration screen from Haiwang, China ZKJ series of high frequency linear vibrating dehydration screens independently developed and produced by Haiwang Company are mainly used in the dehydration, desliming, sand removal and washing of metal ore, non-metallic ore, coal slime, quartz sand, mud , etc. ZKJ-D multi layer high frequency fine vibration screens can be applied in closed circuit grinding and classification process of ferrous and non-ferrous metal mining beneficiation factories, which can obviously decrease the circulation load and improve the beneficiation recovery rate through the combination and assembly with cyclone. | ||

Похожие товары

Лучшее качество Xsd машина для очистки песка

US $1590-$9985

Винтовая пружинная шайба для продажи

US $8000-$9500

Небольшая Мобильная пескомойка 2XL915, пескомойка

US $10000-$40000