T & L бренд FBE2520 автоматический гибочный станок

- Категория: Other Bending Machines >>>

- Поставщик: T&L,(Shanghai),International,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 499800.7 $* | 524790.48 $* |

| Aug-18-2025 | 495600.66 $* | 520380.72 $* |

| Jul-18-2025 | 415800.48 $* | 436590.91 $* |

| Jun-18-2025 | 487200.47 $* | 511560.8 $* |

| May-18-2025 | 424200.95 $* | 445410.4 $* |

| Apr-18-2025 | 478800.62 $* | 502740.68 $* |

| Mar-18-2025 | 474600.13 $* | 498330.1 $* |

| Feb-18-2025 | 470400.60 $* | 493920.95 $* |

| Jan-18-2025 | 466200.27 $* | 489510.59 $* |

Характеристики

|

Technical specifications

- Max. sheet metal size:2500*1250mm

- Min. sheet metal size:400*145mm

- Max. bending height:200mm

- Max. bending length:2500mm

- Max. diagonal dimentions:2800mm

- Max. processing thickness:3.2mm(Q235A),2.5mm(SS),4mm(AL)

- Min. processing thickness:0.5mm

- Max. weight of platform:2000Kg

- Max. height of platform:200mm(include wooden pallet)

- Typical workpiece beat:about 25s(2000mm*750mm*t1.5mm 4 bending each side)

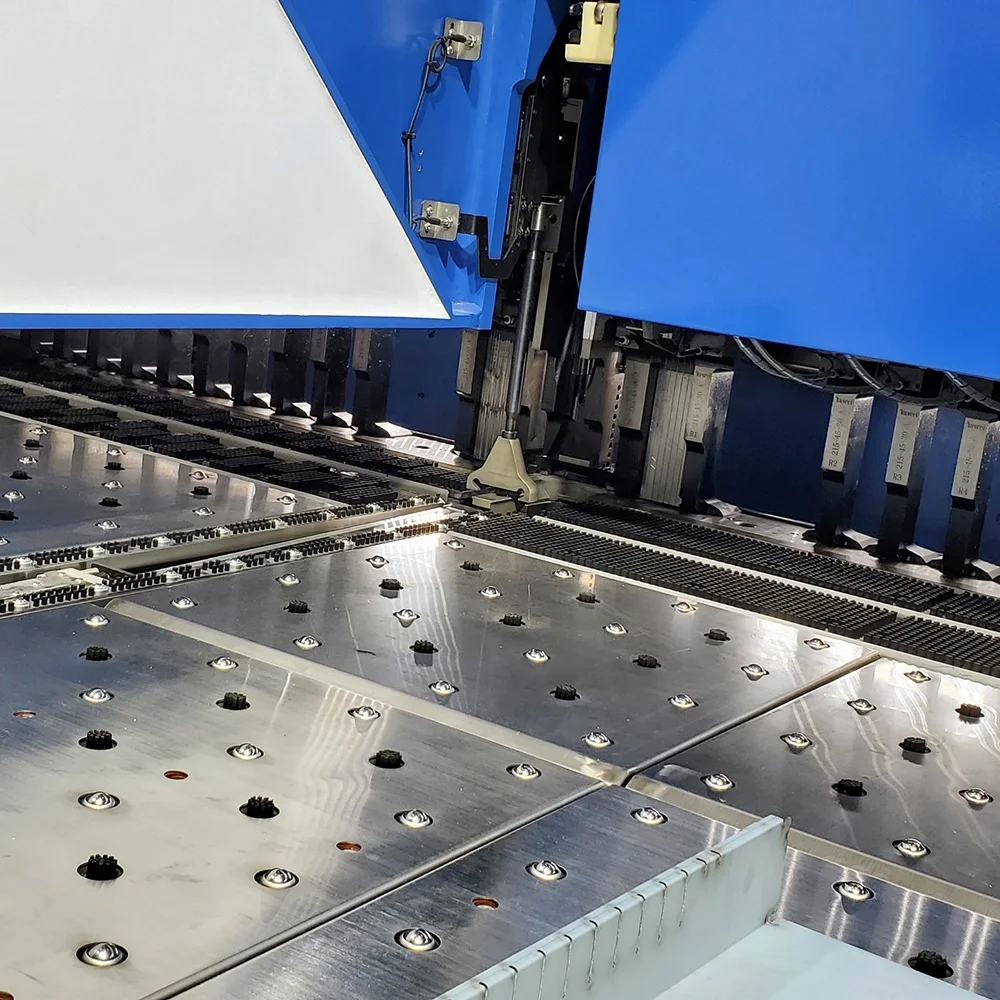

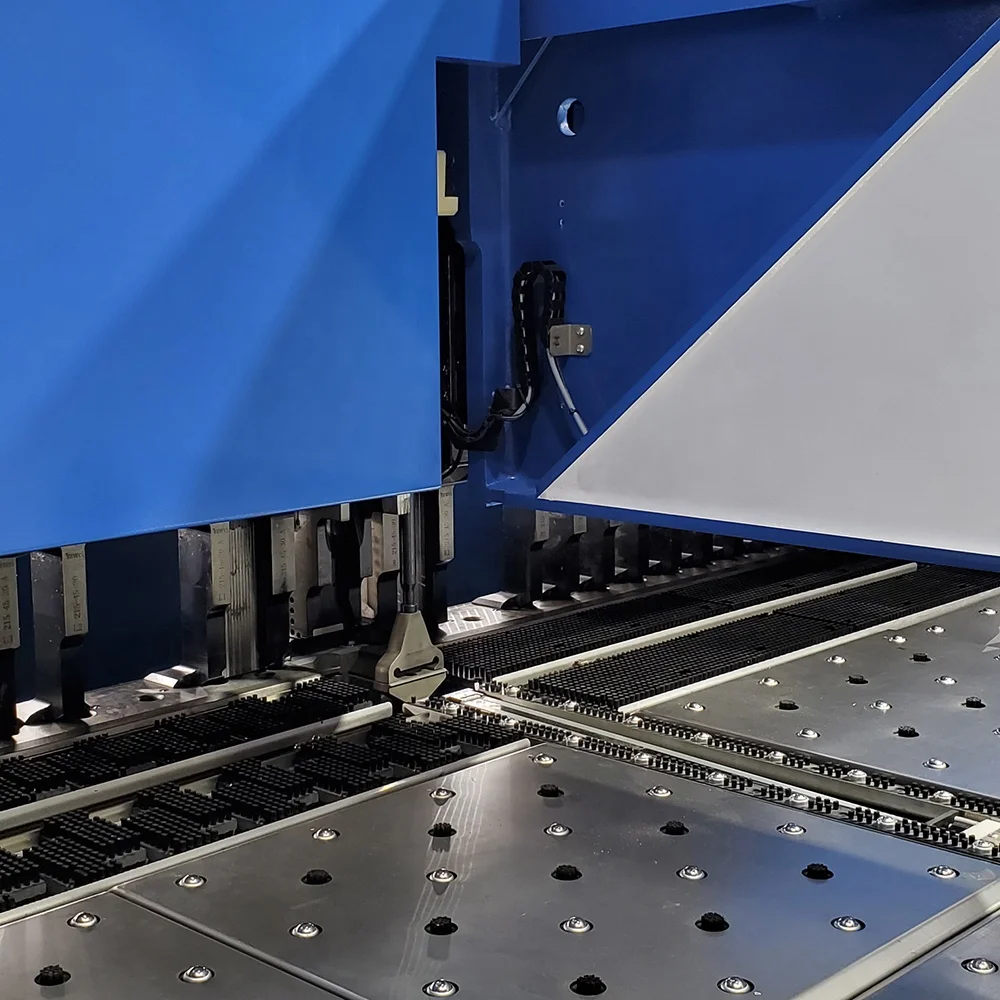

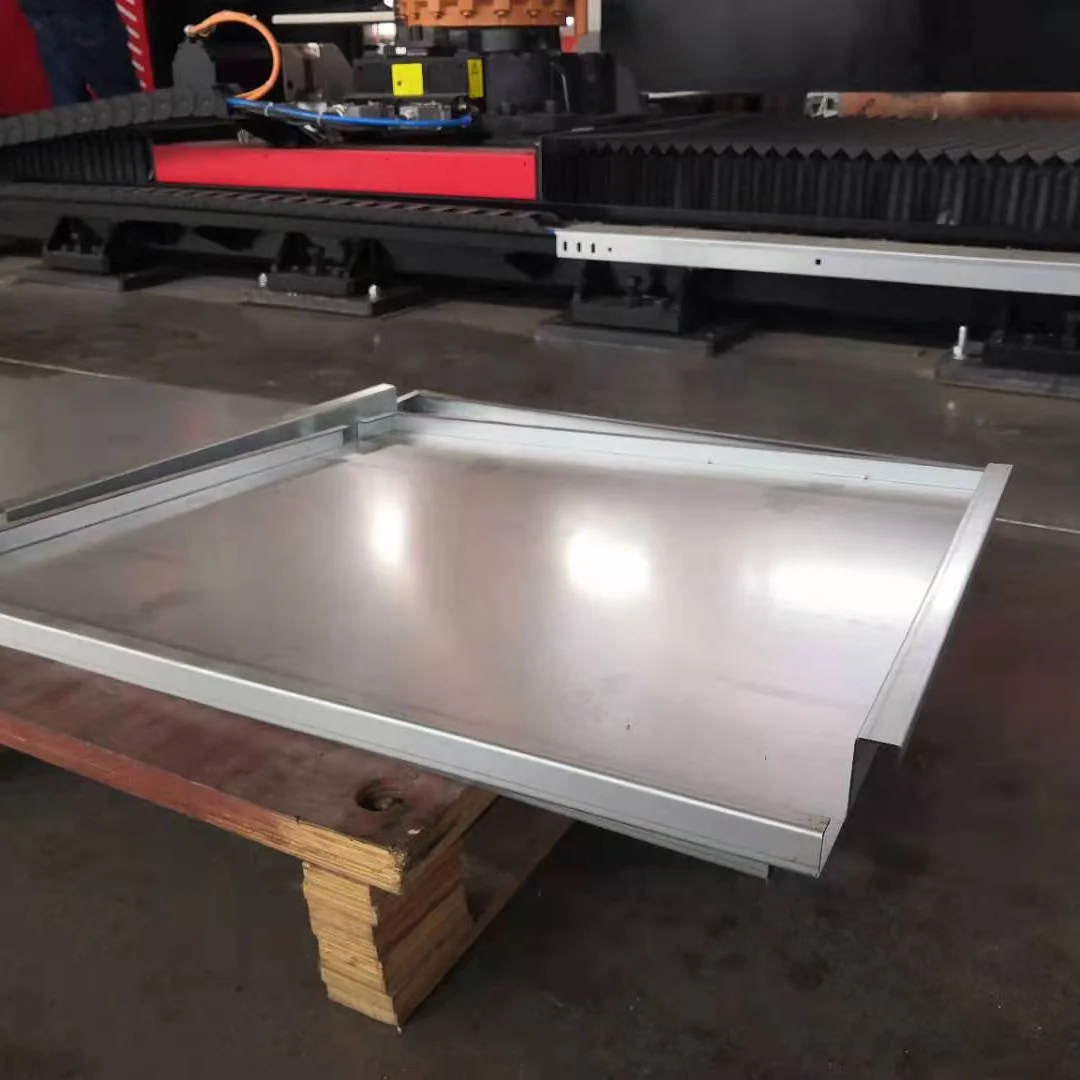

CNC bending machine, It has high quality, high speed and high efficiency bending function, and is generally suitable for automatic bending of box type sheet metal parts. CNC panel bending machine adopts servo-controlled folding and pressing device, 400 kN bending force, 1000 kN pressing/hemming force. Open structure for easy side unloading.

The main motion of bending can be divided to 3 axis, which are respectively the pressing axis, up-and-down swinging axle and forward/backward moving axis. Under the control of CNC system, different motion paths can be run in any combination, thus forming different bending process combination.

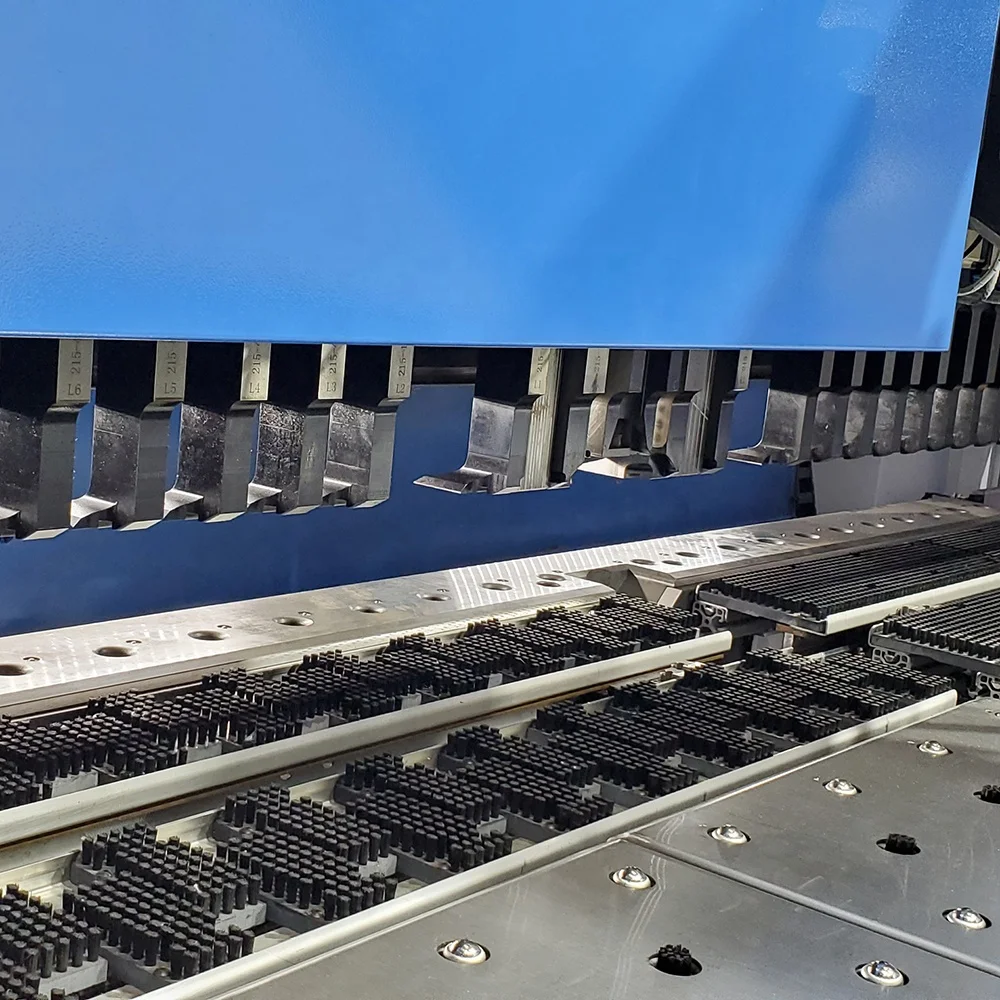

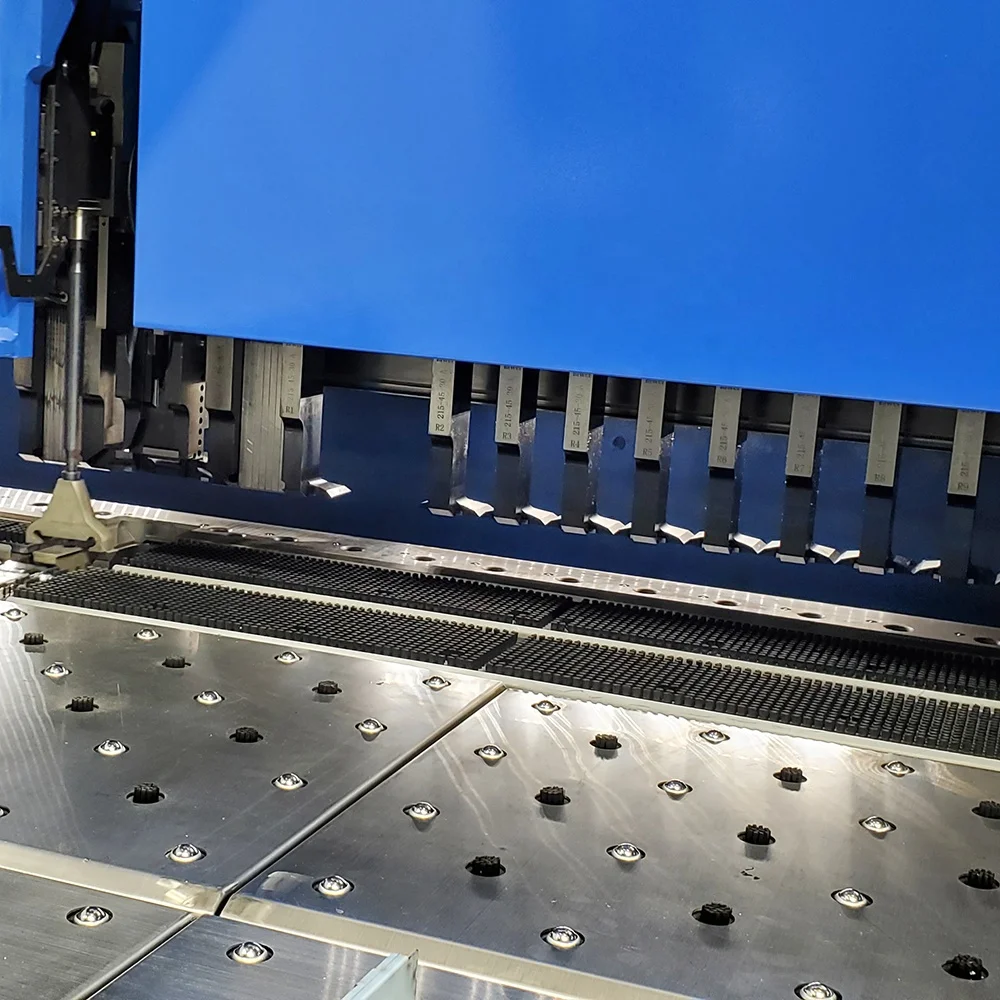

Universal bending dies, bending machine adopt it to realize positive and negative angle bending, large arc, hemming bending, and high efficiency bending of complex section workpiece. Made of die steel, the die adopts high precision processing technology ensures the accuracy and reliability of bending, and the special manufacturing technology ensures the small wear of the die.

1)positive bending 2)negative bending 3)hemming 4)large arc.

Servo-driven bending device, three axis ganged, can achieve a variety of motion track efficient folding. For different materials, different thickness, system can automatically execute different gaps and trajectory. This equipment is energy-saving, environment-friendly, low energy consumption and low noise. Adopting advanced processing technology, processing efficiency is improved obviously, with stable and reliable mechanical structure. The pressing device adopts two-way servo pump control technology, with high speed and low energy consumption. Vertical motion to avoid the impact on the minimum size of the workpiece. The crowning compensation mechanism adopts the special patent structure and has the function of compensating the deformation of the horizontal crowning of die.

Automatic die changing device

It has functions of folding and avoiding, automatic combination and so on. It is convenient to process all kinds of box parts. The die changing device consists of an intermediate avoidance die, a standard segment die, a clutch moving device and a rotating insert die device.

1)segment die driver 2)segment die 3)insert die 4)mediate avoid device 5)insert adjusting device

During bending box, the side edge of the first fold makes the pressing die unable to move up and down directly, so there must be avoidance action. The principle of process avoidance is that the middle avoidance die moves on both sides and the standard section die moves towards the middle so that the die passes over the folded two sides. It should be noted that due to the structural constraints, the corresponding width of the workpiece should be in line with the following table.

The lifting trolley can walk along the guide rail. When stacking, the trolley can be driven to the desired position, and more flexible feeding mode can be selected, such as forklift or driving. The positioning block of sheet metal is on the feeding table, and the whole stacked sheet metal is positioned on the top in both directions of X and Y, thus realizing the pre-positioning between the feeding sheet metal and the machine tool. During the feeding process, the system controls the trolley to rise slightly. Due to the tolerance of the feeding suction trajectory, every 2-3 sheet trolley can rise a certain distance.

Manipulator

- The functions of changing sides, rotating and moving are realized in the horizontal plane

- C-type structure, more flexible and freer space

- Servo driver, linear guide, high precision

Bending manipulator has the function of positioning and rotary transportation of sheet metal. The utility model is composed of a central positioning device, a rotating device, a clamping device, a mobile conveying device and a base. After the sheet is in place, it realizes the function of centering and pressing, and cooperates with the main machine of folding to realize various folding process actions.

1) positioning device 2)rotating device 3)clamping device 4)moving bracket 5)holder

Positioning pushing device will place the plate to be folded in the X and Y directions, which can realize the pre-positioning between the plate and the machine tool. There are two groups of positioning blocks, which can locate the corner and the edge respectively. The combination has nine positioning functions, and the Y direction of the left and right positioning seat can be adjusted (+50mm) to adapt to the positioning function of various sheets.

Compressing device realizes reliable compaction by servo-driven screw driving connecting rod, and can realize reliable clamping of plates of different materials and thickness.

Rotating device realizes the rotation of the rotating block by servo driving motor and reducer. The high precision encoder realizes closed-loop control, and the rotation accuracy is stable and reliable.

The servo drive motor drives the precision ball screw to achieve stable and reliable feeding accuracy. The C frame is analyzed and optimized by finite element analysis, and the moderate lightweight achieves the balance between rigidity and high efficiency.

Main structure and features

Company independently designs, imported key drive and control parts. The unit mainly consists of loading pallet, loading device, plate conveying device, flanging machine, feeding machine, discharging device and electrical control system.

High strength frame

The frame adopts an open "C" structure, which is good for opening. The frame is made of steel structural parts, and after welding, the internal stress is removed by tempering the large tempering furnace.

By finite element analysis, the frame has high strength and low deformation

Main parts list

Items | Name | Brand |

| 1 | CNC system | GermanySiemens |

| 2 | Feeding servo motor and driver | GermanySiemens |

| 3 | Linear guide and ball screw | Taiwan PMI |

| 4 | Air processing quad | Japanese SMC/Germany FESTO/AIRTAC |

| 5 | Two five-way solenoid valve, two three-way solenoid valve | SMC |

| 6 | Breaker, contactor | GermanySiemens |

| 7 | Button | France Schneider |

| 8 | Proximity switch | Germany BALLUF |

| 1. Standard Service: |

Our factory provide the service for the customer forever, if the customer need operation help, can contact us by MSN, Skype, Email and Telephone at any time, we provide 24 hours on-line service. |

| 2. Installation: |

Our factory can send our engineer to the customer’s factory install, commission and training freely .The customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely. |

| 3. Quality Guarantee: |

Our guarantee time is 2 Years from B/L Date ,If any component is damaged during guarantee time,we can send the component to the customer By DHL,TNT freely. |

| 4. Order Processing: T&L Brand FBE2520 Automatic Panel Bender, Panel Bending cnc center |

|