Ананасовый сок кокосовые напитки алюминиевые жестяные банки закаточная машина жидкий продукт может

- Категория: Sealing Machines >>>

- Поставщик: Guangdong,Xtime,Packaging,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 171.50 $* | 174.20 $* |

| Jul-19-2025 | 139.50 $* | 142.38 $* |

| Jun-19-2025 | 169.46 $* | 172.60 $* |

| May-19-2025 | 167.99 $* | 170.42 $* |

| Apr-19-2025 | 134.89 $* | 137.52 $* |

| Mar-19-2025 | 165.17 $* | 168.93 $* |

| Feb-19-2025 | 163.97 $* | 166.77 $* |

| Jan-19-2025 | 162.42 $* | 165.4 $* |

Характеристики

- Product introduction

1.1 The product is mainly appropriate to seal all kinds of rounded PET can, tin can, aluminum can

and paper can with advanced product design, reasonable structure and easy and simple operation.

It is necessary and ideal packaging equipment of food, medicine, tea, chemical engineering and

other industries.

1.2 Stainless steel is adopted for the main part of the product. The appearance is attractive and

design requirements of most standardized production workshop are satisfied.

1.3 Single motor is adopted for operation and all components and parts are processed precisely.

Production technology and process have the advantages of low noise and low failure rate

through sedimentation and constant improvement of the Company.

1.4The product conforms to regulations of national standards, departmental standards and enterprise

standards and can be allowed to leave the factory after qualification of strict inspection and test.

- Switching declaration of panels and all buttons:

- Ampere meter: display current value of equipment

- Power supply indication: when red indicating light is on, it shows equipment has been electrified; when light is off, it

shows equipment does not have electricity.

- Operation indication: when green indicating light is on, it shows that equipment is in service; when light is off, it shows

that equipment is in stop working state.

- Automation: the equipment cycles automatically and conducts reciprocating can sealing constantly when it is moved to

automatic state.

- Inching: electric foot switch is pressed each time, the equipment has once micro operation when moved to automatic

state. The function is mainly used for adjusting machines.

- Manual operation: electric foot switch is pressed each time, the equipment has once complete can sealing when moved

to manual state, that is to say, the switch is pressed each time, the equipment completes sealing movement of the can once.

- Emergency stop: the button can be pressed in case of emergency. Then the equipment is in stopped state immediately

and any other switches fails to work. The button is rotated in counterclockwise direction and the button pops up

automatically and restore function if it needs removed.

- Switch on/turn off: switching on refers to connecting a circuit for the equipment while turning off refers to breaking a

circuit for the equipment.

- Foot (manual) switch: operation of electrical machine is triggered by the switch directly. There are different function for

matching with manual operation, automatic operation and electric operation. The switch must be in safe position if the

equipment is temporarily closed.

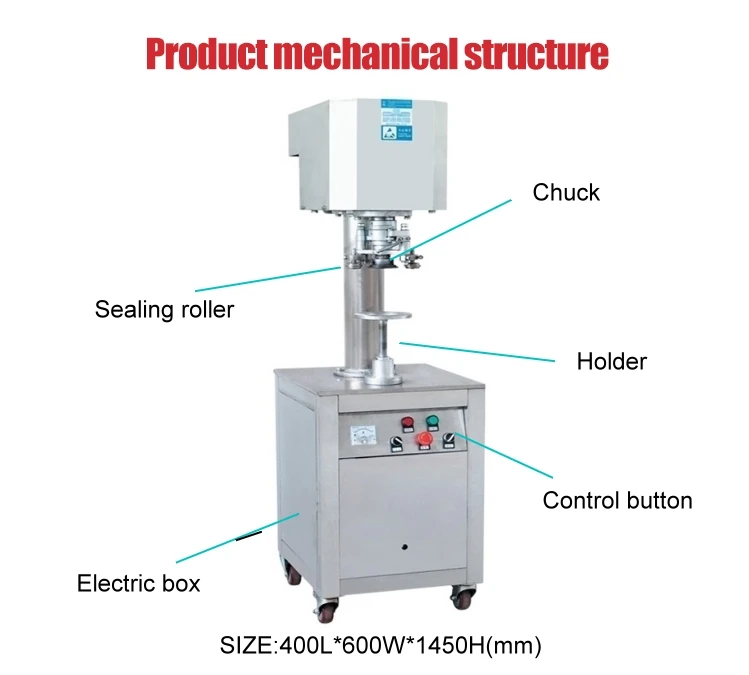

3.Structure, part name and description

4. Characteristics and main technical parameters | ||||||||

Project | XT-FGJ-100C | |||||||

Performance description | 1. Two seaming rolls are adopted for sealing. Roll rim is finished by the first hob and blank pressing is finished by the second hob. The structure is simple and adjustment is convenient; 2. The latest generation of machine design is adopted. The sealing is finished by rotation of sealing hob without rotation of can body in the sealing. It is reliable and safe and especially appropriate for can sealing and packaging of fragile products and liquid products; 3. Operation of hob and rise and fall of can body are controlled by mechanical cam with stable and reliable operation. | |||||||

Main characteristics | 1. The main feature of the latest generation design of can seamer is non rotation of can body in the process of sealing, which avoids shift and scatter of product put well in the can. 2. The operation is easy and sealing can be finished only by one click. 3. The machining precision is high. Whole stainless steel materials are adopted for main part to design and manufacture which conforms to design requirements of manufacturing workshop. | |||||||

Technical parameters | Material: stainless steel No. of sealing head : 1 Production capacity: 10-20cans/min. Support can height: 50-200mm Applicable bottle diameter: 35-130mm Operating voltage: AC220V 50/60Hz Power: 0.55KW Weight: 120KG Size: 400*600*1450mm | |||||||

- Framework principle and operation method

Double sealing principle is adopted for the equipment. The procedure of clenching, folding and

flattening by cover side and can side is utilized so as to achieve sealing effect. The forming steps

are as follows:

(1) The can cover is put in the head of can trunk. The can edge is jogged in the opening part of

internal cover edge in the tan cover.

(2) The can body is lifted upward and tan cover is jogged in the rolling head by pressure of lifting

tan tray.

(3) Cover edge is rolled inwards by the first roll gear with one side cycling cover edge for relative

rotation movement and the other side exerting pressure towards axis.

(4) The second roll gear continues to compress the first seaming formed by the first roll gear and to

form the second seaming, then seaming is finished after the first roll gear finishes operation.

(5) The can tray is downward and rolling head is downward to exit empty can. The forming steps

are shown in the figure below.

Main points of adjusting machine and diagram

The left diagram is the first hob and the knife edge with

hooked groove is deeper than the second hob. It rolls

rim in the process of sealing. Reference distance

between the first hob and pressure head is shown in the

fig.

The left diagram is the second hob with relatively

smooth knife edge and without hooked groove. The

second hob has the function of blank pressing in the

process of sealing. Reference distance between the

second hob and pressure head is shown in the fig.

Small rearing in the tool arm rotates with rotation of

cam shaft. The left seaming roller is corresponding

with lower cam and the right seaming roller is

corresponding with upper cam. According to lever

principle, when lower small rearing reaches small cam,

the seaming roller enters seaming slowly at this time

and the can theoretically is lifted to the position

compressing with chuckexactly, so the position is the

best opportunity to adjust height of screw rod .

According to lever principle, when the small rearing

reaches the highest point of corresponding small cam,

it is the time with closest distance between seaming

roller and chuck and also the most important operation

time of seaming roller. The distance between seaming

roller and chuck is adjusted in the position.