Автоматический профильный светильник стальной каркас домашняя конструкция LGS машина для холодного формования

- Категория: Steel Frame & Purlin Machines >>>

- Поставщик: Guangzhou,Kingreal,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 101150.52 $* | 106208.48 $* |

| Aug-15-2025 | 100300.86 $* | 105315.65 $* |

| Jul-15-2025 | 84150.6 $* | 88358.16 $* |

| Jun-15-2025 | 98600.70 $* | 103530.10 $* |

| May-15-2025 | 85850.94 $* | 90143.45 $* |

| Apr-15-2025 | 96900.80 $* | 101745.9 $* |

| Mar-15-2025 | 96050.94 $* | 100853.21 $* |

| Feb-15-2025 | 95200.55 $* | 99960.64 $* |

| Jan-15-2025 | 94350.14 $* | 99068.62 $* |

Характеристики

Products Description

Automatic FrameMac Light Gauge Steel Framing House Structure

LGS Cold Roll Forming Making machine

This light gauge steel framing C channel profile roll forming machine is specially designed for the

production of light steel villa house structure. Only need to input the technical drawing of the steel villa housing structure.

production of light steel villa house structure. Only need to input the technical drawing of the steel villa housing structure.

The machine will automatically calculate the raw materials consumption, holes punch positions, each section lengths by the industrial computer installed on the equipment. Then it will start the production one by one according these data and jet the code on each section for easy fabrication. It can save many labors cost and achieve fully automatic production.

The machine includes uncoiler, straightener, multi pre-punch stations, main roll forming machine, code inkjet machine, shearing machine, automatic control system.

According with the prefabricate request for the light gauge steel framing structure, the machine includes mold sets for the production of: dimple screw hole, chamfer, web through hole, small side shear, pipeline hole, web shrinkage, shearing and other stamping die and coding device

Our company has established a long-term friendly relationship with the famous Dutch roller design company "HDE".Relying on the

powerful design capabilities and technical support of HDE, our company can carry out rolling processing of various complex profile

products. And to a certain extent, our overall processing technology level has been improved.

powerful design capabilities and technical support of HDE, our company can carry out rolling processing of various complex profile

products. And to a certain extent, our overall processing technology level has been improved.

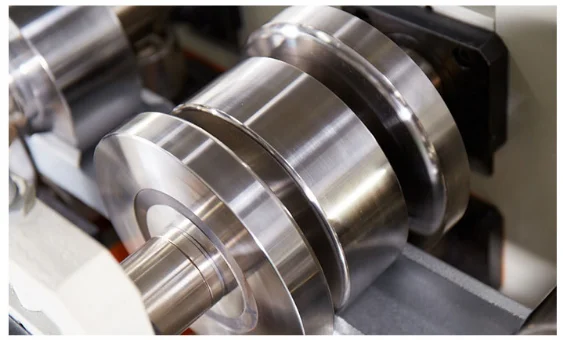

STRICT MACHINE QUALITY CONTROL

SYSTEM

SYSTEM

Our company has a strict machine quality control system to inspect different components.For instance,we will do detailed

measurement and inspection for each forming roller ——the key component of a roll forming machine,and deflection test after

installation. All sort of methods would be taken to ensure accuracy of machines and finished products.

measurement and inspection for each forming roller ——the key component of a roll forming machine,and deflection test after

installation. All sort of methods would be taken to ensure accuracy of machines and finished products.

Our company can customize LOGO according to customer’s requirements. For different products,we provide LOGO rolling, stamping,

laser coding and other solutions. Customerized LOGO can enhance the company’s image and bring publicity.

laser coding and other solutions. Customerized LOGO can enhance the company’s image and bring publicity.

Certifications

Our products have passed the international ISO9001 and European CE certification,

and being exported to many European countries.

Why Choose Us

Related products

Company Profile

KINGREAL UNIVERSAL INDUSTRIAL LIMITED is established on 1995 and is dedicated on researching, desgin and metal ceiling production factory manufacturing all kinds of metal ceiling perforation production line, HVAC Duct Auto Manufacture Line, T bar roll forming machine, metal slitting line, cut to length line, acoustical ceiling tile textile install machine, cold roll forming machine and etc.

Our machinery and production line had been exported to Turkey, Saudi, UAE, Russia, etc and win good reputation all around the world.We warmly welcome old and new customers from all over the world to visit our company and establish business relationships with us. We do believe our mutual cooperation will create a brilliant future.

Our machinery and production line had been exported to Turkey, Saudi, UAE, Russia, etc and win good reputation all around the world.We warmly welcome old and new customers from all over the world to visit our company and establish business relationships with us. We do believe our mutual cooperation will create a brilliant future.

Product packaging

For different machines or production line parts, we have different packing solutions:

* For the machine or production line, using plastic film to cover and wrap. Then will be loaded to the container by forklift or crane.

* For the key parts such as the roll forming rollers set, we will use the metal frame to package.

* For the electrical cabinets, molds set, we will use wooden carton to package and load.

* For the electrical cabinets, molds set, we will use wooden carton to package and load.

FAQ

Q:What's your Warranty ?

12 months, during which all parts damaged because of quality problem will be changed for free.

Q: What's your delivery Time ?

Within 45-60 days after receiving prepaid. Some machines in stock, can be delivered at any time.

Q: What's your payment terms ?

30% deposit is paid before production, the balance paid after inspection confirmation before shipment.

Q:What's your Install and Training ?

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, manual and video is provided to show how to install and operate.

Q: What's you after-sale service ?

We provide 24-hour online service for our customers.

A.The seller will debug the machines freely in China, and the traffic expense in China of the technique people will be paid by the seller. When technique men go to the buyer's place to debug the machines, the buyer should pay the expense of accommodation, and traffic for the buyer’s men.

B. If the buyer sends people to receive the training of the operation given by the seller, during the training period, the seller should pay the expense of accommodation, and traffic for the buyer's men.

Q: How to place order ?

Inquiry---confirm the profile drawings and price----confirm the PI---arrange the deposit or L/C---then OK

12 months, during which all parts damaged because of quality problem will be changed for free.

Q: What's your delivery Time ?

Within 45-60 days after receiving prepaid. Some machines in stock, can be delivered at any time.

Q: What's your payment terms ?

30% deposit is paid before production, the balance paid after inspection confirmation before shipment.

Q:What's your Install and Training ?

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, manual and video is provided to show how to install and operate.

Q: What's you after-sale service ?

We provide 24-hour online service for our customers.

A.The seller will debug the machines freely in China, and the traffic expense in China of the technique people will be paid by the seller. When technique men go to the buyer's place to debug the machines, the buyer should pay the expense of accommodation, and traffic for the buyer’s men.

B. If the buyer sends people to receive the training of the operation given by the seller, during the training period, the seller should pay the expense of accommodation, and traffic for the buyer's men.

Q: How to place order ?

Inquiry---confirm the profile drawings and price----confirm the PI---arrange the deposit or L/C---then OK

Похожие товары

Гидравлический разматыватель

US $7500-$9500

Силос прогонами машина низкая цена

US $43000-$45000

Машина для прокатки холодных секций c purlin

US $21000-$22000