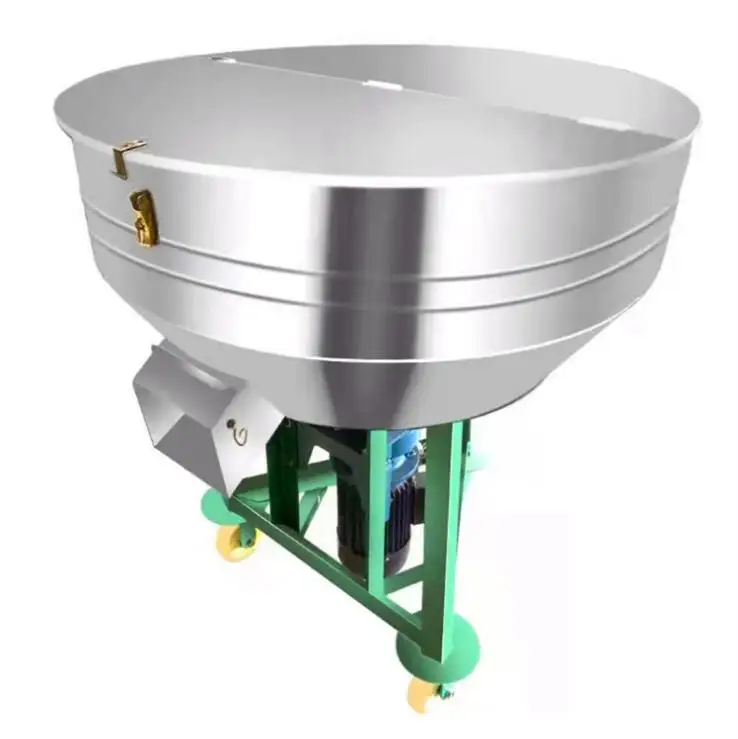

High Speed Mixer Plastic Raw Material plastic drying mixer PVC Mixing

- Категория: Plastic Mixer >>>

- Поставщик: Laizhou,Haolong,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-18-2025 | 52861.41 $* | 53918.81 $* |

| Jul-18-2025 | 42872.90 $* | 43729.88 $* |

| Jun-18-2025 | 52029.2 $* | 53070.95 $* |

| May-18-2025 | 51613.60 $* | 52645.11 $* |

| Apr-18-2025 | 41207.91 $* | 42031.52 $* |

| Mar-18-2025 | 50780.29 $* | 51796.74 $* |

| Feb-18-2025 | 50364.43 $* | 51371.44 $* |

| Jan-18-2025 | 49948.82 $* | 50947.7 $* |

Характеристики

PVC EVA TPR PE PET Color Mixing Pellets Vertical Resin Plastic Granules Mixer plastic color mixer for injection molding

The mixer is composed of a horizontal rotating container and rotating vertical mixing blades. When the molding material is stirred, the container turns to the left and the blades turn to the right. Due to the action of countercurrent, the movement direction of each particle of molding material crosses and the chance of mutual contact increases. The extrusion force of countercurrent mixer is small, the calorific value is low, the mixing efficiency is high and the mixing is more uniform.

Advantage

1. Put an end to the dust pollution, improve the working environment, reduce the pollution of the environment and personnel to the materials, and improve the cleanliness;

2. Due to the pipeline transportation, it takes up a small space, and can complete the powder transportation in a narrow space, making the workspace beautiful and generous;

3. It is not limited by long and short distance. At the same time, the vacuum feeder can reduce the labor intensity and improve the work efficiency;

4. It is the best way to transport most powder materials.

5. It is suitable for powder products with good fluidity and meets GMP standard.

6. It can be designed in many ways according to different materials, various vacuum sources and negative pressure workstation

Technical Parameters

Type | Moldel | Power | Motor power | Mixing capacity | External Size | Weight |

V | Kw | Kg/min | Mm | Kg | ||

Horizontal | HXHS-100KG | 380V3¢ | 3 | 100/3 | 1150*800*1300 | 280 |

HXHS-150KG | 4 | 150/3 | 1400*800*1300 | 398 | ||

HXHS-200KG | 4 | 200/3 | 1376*750*1465 | 468 | ||

Roling Barrdl Type | HXHS-50KG | 0.75 | 50/3 | 820*950*1300 | 120 | |

HXHS-100KG | 1.5 | 100/3 | 1100*1100*1450 | 155 | ||

Vertical | HXHS-50KG | 1.5 | 50/3 | 860*740*1110 | 120 | |

HXHS-100KG | 3 | 100/3 | 1200*1150*1480 | 230 | ||

HXHS-150KG | 4 | 150/3 | 1300*1200*1550 | 180 | ||

HXHS-200KG | 5.5 | 200/3 | 1400*1200*1550 | 260 |

Application Fields

Plastic Granules

Fertilizer particles

Feed pellet

Spice powder

Distiller's grains

Seed coating

Product Exhibition

Working features

1. It is easy to install and can be moved. If multiple mixers use the same material, only one feeding machine can feed multiple mixers at the same time, which avoids the trouble of manual processing and makes the feeding work safer, more time-saving and more labor-saving.

2. Compared with the vacuum feeder, it can avoid the trouble of cleaning the filter frequently.

3. It adopts international advanced electrical control components and famous brand motor to ensure the safe and reliable operation of the system, with the conveying capacity of 1 person, and the maximum loading capacity of 3 tons per hour.

4. This machine has a wide range of applications. It can be used for powder, plastic particles, powder mixture, crusher, powder and particle transportation in the process of medicine and chemical production.

5. Compared with traditional vacuum feeder and spring dust feeder, the energy consumption is only about one third.

Recommend Products

Packing & Delivery

Ex Factory Delivery:

The device is fully calibrated prior to shipment from the factory. In order to meet the long-distance transport. Repeatedly handling storage needs, to ensure the integrity of the safety equipment to reach the contract factories, all of the packaging equipment to secure solid, according to the national packaging standards related to the implementation of standards and design requirements.

![]()

![]()

![]()

![]()

![]()

![]()

Packing:

1.Standard wooden case.

2.Customized packaging can be available.

![]()

Shipping:

We can ship the goods to you by International Express such as DHL,UPS,TNT,EMS and so on, you can also choose the appropriate one based on your timeline and budget.

Besides, you can choose to use your own forward.

Company Profile

![]()

Laizhou Haolong Machinery Co., Ltd

Laizhou Haolong Machinery Co., Ltd. specializes in granulators, plastic granulators, crushers, flue gas treatment, flue gas

purification, feeding machines, foam granulators, chemical machinery, chemical machinery, flue gas purification and other

products.

purification, feeding machines, foam granulators, chemical machinery, chemical machinery, flue gas purification and other

products.

The production and processing company has a complete and scientific quality management system. The integrity, strength

and product quality of Laizhou Haolong Machinery Co., Ltd. have been recognized by the industry. Friends from all walks of life

are welcome to visit, guide and negotiate business.![]()

![]()

![]()

![]()

and product quality of Laizhou Haolong Machinery Co., Ltd. have been recognized by the industry. Friends from all walks of life

are welcome to visit, guide and negotiate business.

Laizhou Haolong Machinery Co., Ltd. has always paid attention to product brand building and maintenance. Brand is quality,benefit, competitiveness, and vitality. The pursuit of famous brands is the pursuit of excellence. The company always adheres to the quality policy of "innovation for high quality, integrity for brand", and vigorously implements the famous brand development strategy, starting from focusing on characteristics, focusing on brand, focusing on market, focusing on efficiency, and achieving standards only has characteristics, and characteristics only has brand , There is a consensus that there is a market for a brand, and there is a market for benefits. Carry out brand awareness and brand culture construction, do a good job in brand management, brand promotion: use innovation, quality, integrity, service, and cost-effective to carefully build Haolong machinery to further enhance the reputation in the industry.

![]()

Certifications

![]()

Customer Photos

![]()

![]()

![]()

![]()

Contect us

![]()