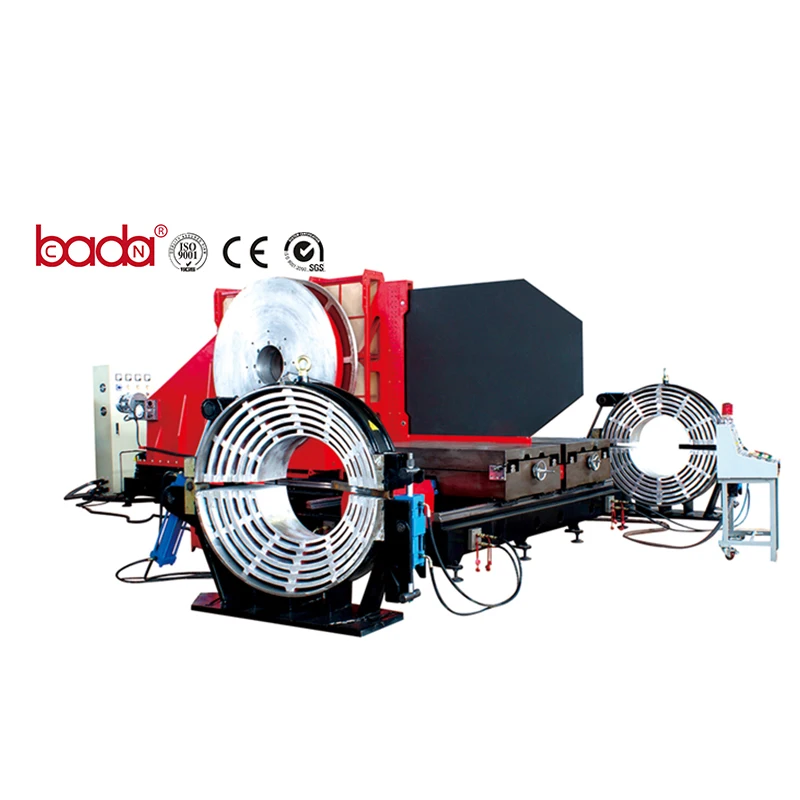

800 band saw butt welding machine workshop multi-angle fitting hdpe

- Категория: Arc Welders >>>

- Поставщик: Jinan,Bada,Plastic,Pipe,Welding,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 5869808.81 $* | 6163298.15 $* |

| Aug-17-2025 | 5820482.62 $* | 6111506.59 $* |

| Jul-17-2025 | 4883286.47 $* | 5127450.69 $* |

| Jun-17-2025 | 5721830.53 $* | 6007922.83 $* |

| May-17-2025 | 4981938.65 $* | 5231035.4 $* |

| Apr-17-2025 | 5623178.95 $* | 5904337.61 $* |

| Mar-17-2025 | 5573852.73 $* | 5852545.70 $* |

| Feb-17-2025 | 5524525.71 $* | 5800751.52 $* |

| Jan-17-2025 | 5475199.4 $* | 5748959.27 $* |

Характеристики

SHBG800 Workshop multi-angle poly pipe butt fusion welding machine hdpe fabrication

Our advantage:

1) CE, SGS, ISO9001 certificate

2) Provide on line video technique teaching of fusion welding

3) 2 years warranty

4) Provide customized welding machine

Brief introduction of SHBG800 Workshop multi-angle poly pipe butt fusion welding machine hdpe fabrication

1) Suitable for welding of plastic pipes and fittings made from PE, PP & PVDF.

2) Easy to use

3) Welding position can transform that it is convenient for welding all kinds of pipe fittings.

|

Model |

SHBG800 multi-angle butt fusion welding machine

|

|

Pipe Sizes(mm) |

500-800mm |

|

Application |

0~90°elbow, tee, cross,wyes |

|

Pressure adjustment range |

16MPa |

|

Working Voltage |

380V,50Hz |

|

Total Power |

47kw |

|

Machine frame material |

aluminum ZL104 |

|

Gross weight |

|

|

Package size |

|

1. Using Teflon coating material imported from Japan, after twice coating and three processes.

2. The solid core of the Heating plate is thickened and non-stick tube, the heat transfer is even, supporting the aviation connection line to ensure the contact safety of the power supply.

3. Compared with other manufacturers, the thickness of Heating plate is increased by 5mm, and the heat storage and thermal conductivity are strong.

1. Timer, pressure gauge, temperature controller and alarm shall be installed on the operating table to facilitate observation and improve welding efficiency.

2. The temperature controller and pressure regulating valve are CE certified, and the control precision can reach 0.01%.

3. The hydraulic station is installed with an accumulator, which can realize the function of automatic pressure replenishment and reduce the number of manual pressure replenishment.

1. High power milling cutter, mirror cutter disk, strong motor, high concentricity, smooth milling.

2. High-power Bosch drill is adopted for milling motor, which is strong and strong without slipping

3. The milling cutter is equipped with a limited position switch, which can be rotated only when placed in the frame to prevent accidental injury.

Jinan Bada plastic pipe welding equipment Co., Ltd. is a 23 years professional top manufacturer with CE, SGS, ISO9001 certificate, our product have low repair rate and 2 years warranty, the company participated in the drafting of GB and cooperated with well-known universities to train welding technology talents. The company has a large number of spare parts inventory, and can customize welding machines with different standards such as American Standard, British standard and German standard, so as to meet the needs of all customers.

Our products including: Hydraulic Butt Fusion Machines, Manual Butt Fusion Machines,Electrofusion Welding Machines, Socket Fusion Welding Machines, Workshop Fitting Welding Machines, HDPE Fittings, Electrofusion Fittings, ect.

WHY US

1) Advanced laboratory

2) Mature fusion welding technology

3) Spare parts warehousing quality inspection, inspection during the production process, complete machine inspection and commissioning before delivery.

4) Cooperate with well-known universities, participate in the drafting of GB national standard, provide training for fusion welding technicians at home and abroad, and support free online video guidance.

5) Sufficient spare parts inventory, short delivery time, less than 50 sets, delivery time 7-10 working days, in line with ROHS 2.0 standard.

1) Advanced laboratory

2) Mature fusion welding technology

3) Spare parts warehousing quality inspection, inspection during the production process, complete machine inspection and commissioning before delivery.

4) Cooperate with well-known universities, participate in the drafting of GB national standard, provide training for fusion welding technicians at home and abroad, and support free online video guidance.

5) Sufficient spare parts inventory, short delivery time, less than 50 sets, delivery time 7-10 working days, in line with ROHS 2.0 standard.

Related products