High Quality Horizontal ASME Approved Composite

- Категория: Pressure Vessels >>>

- Поставщик: Taian,Strength,Equipments,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 4864708.11 $* | 5107943.90 $* |

| Aug-20-2025 | 4823828.86 $* | 5065019.86 $* |

| Jul-20-2025 | 4047110.78 $* | 4249466.54 $* |

| Jun-20-2025 | 4742068.89 $* | 4979171.29 $* |

| May-20-2025 | 4128870.62 $* | 4335314.39 $* |

| Apr-20-2025 | 4660309.97 $* | 4893324.31 $* |

| Mar-20-2025 | 4619429.41 $* | 4850400.22 $* |

| Feb-20-2025 | 4578549.90 $* | 4807476.33 $* |

| Jan-20-2025 | 4537669.39 $* | 4764552.55 $* |

Характеристики

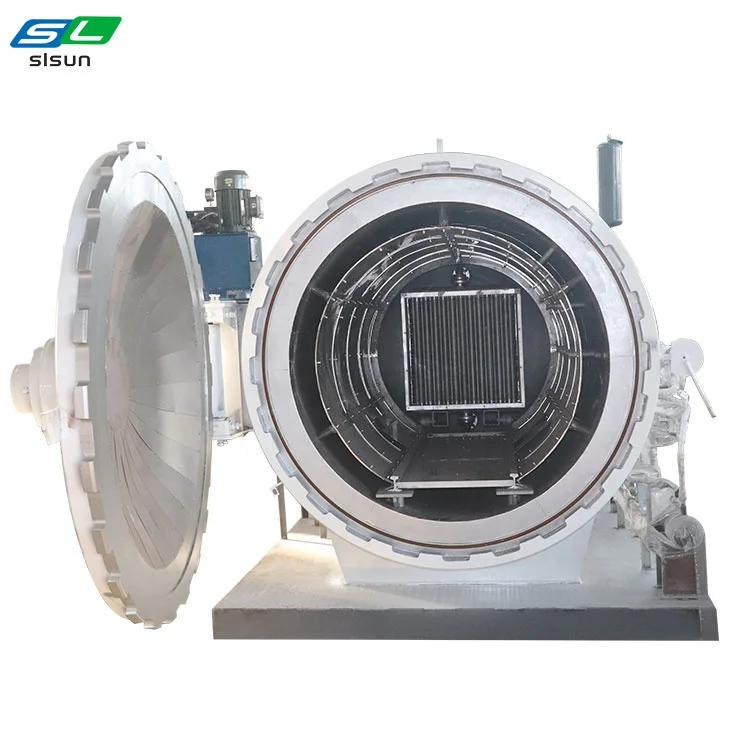

Composite Autoclave (also called carbon fiber autoclave ) is the pressure vessel specially designed and manufactured to fabricate composite material, carbon fiber autoclave is one of the our hot sale industrial autoclave products. Carbon fiber autoclave(also called a composition material or composite) is made from two or more constituent materials with significantly different physical or chemical properties that produce a material with characteristics different from the individual components when combined. Composite autoclave is one of the effective and most applicable techniques for composite production. In the composite manufacturing process, the assembly of a two-sided mold set that forms both surface of the panel is placed into the industrial autoclave which provides both required elevated pressure and elevated temperature.

Specifications of Composite Autoclave | ||||||

Effective Diameter (mm) | 600-6,000 | |||||

Effective Length (mm) | 800-300,000 | |||||

Maximum Working Pressure (Mpa) | 0.2-10 | |||||

Maximum Working Temperature (℃) | 100-500 | |||||

Temperature Control Accuracy (℃) | ±0.5-±3.0 | |||||

Tank Temperature Uniformity (℃) | 1.0-3.0 | |||||

Pressure Control Accuracy (Mpa) | ±0.01 | |||||

Vacuum Limit (Kpa) | ≤2 | |||||

✳Remark: Other specifications can be customized according to specific requirements. | ||||||

Features of Composite Autoclave

①Turn key solution for large, high productive units to lab autoclaves.

②Integrated system design with over 20 years of industrial experiences.

③Professional modular manufacturing.

④Computer control system specifically for composite autoclave use.

⑤Automatic control of over pressure or temperature protection, door safety interlock.

⑥High quality, energy saving.

⑦Customized installation to satisfy your demands.

⑧Safe operation, over pressure and temperature protection, door safe interlock.

⑨Advanced composite curing and bonding process.

⑩Reliable and efficient operation.

⑪Custom designs to suit your needs.

⑫Easy to operate, longer service life.

Product Display

Interior thermal insulation

Internal sheet metal: Insulation liner, stailess steel 304.

Mineral wool insulation: 100mm. Ceramic aluminum silicate ceramic folding cotton.

Motor& fans air flow

Heating system

Electric heating via inconel (Stailess steel ) tubular heaters.

Heaters mounted back at end of autoclave which moving wheels for easy system maintenance.

Two linear regulator for heating power , each unite guarantee heating work efficient and energy saving.

Cooling system

Proportional cooling valve for main cooling control. Computer controlled.

Air spray and Mist water valves for trim cooling control. Computer controlled.

Canada customer visited our factory for carbon fiber autoclave

Sudan customer visited our factory for carbon fiber autoclave

Carbon fiber industrial autoclave (DN3000*6200mm) exported to Malaysia.