28/36/48 inch high pressure sand filters

- Категория: Water Filter >>>

- Поставщик: Hunan,Dawning,Filter,System,Technology,Co.,Ltd.,[Hunan,China]Hunan

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 182094.84 $* | 191199.51 $* |

| Aug-18-2025 | 180564.37 $* | 189592.61 $* |

| Jul-18-2025 | 151490.52 $* | 159065.17 $* |

| Jun-18-2025 | 177503.30 $* | 186378.79 $* |

| May-18-2025 | 154550.46 $* | 162278.11 $* |

| Apr-18-2025 | 174443.43 $* | 183165.97 $* |

| Mar-18-2025 | 172913.75 $* | 181559.62 $* |

| Feb-18-2025 | 171382.55 $* | 179951.14 $* |

| Jan-18-2025 | 169852.21 $* | 178345.79 $* |

Характеристики

28/36/48 inch high pressure sand filters

| Product Description |

Application

- Commercial - Golf course and sporting field irrigation systems.

- Industrial - Pre-preteatment of UF/RO and waste water recycling.

- Irrigation - Primary filtration for the prevention of blockages in irrigation system

- HVAC- cooling tower side filtration and full system

- Metal Processing Plants - Filtration for water cooling and spray nozzles.

- Mining - Cleaning of process and waste water.

Technical requirements

- Min. pressure: 0.2Mpa

- Max. pressure:1.0Mpa

- Working temperature:<65℃

- Water in/out: 4 inch

- Power:220V/50Hz

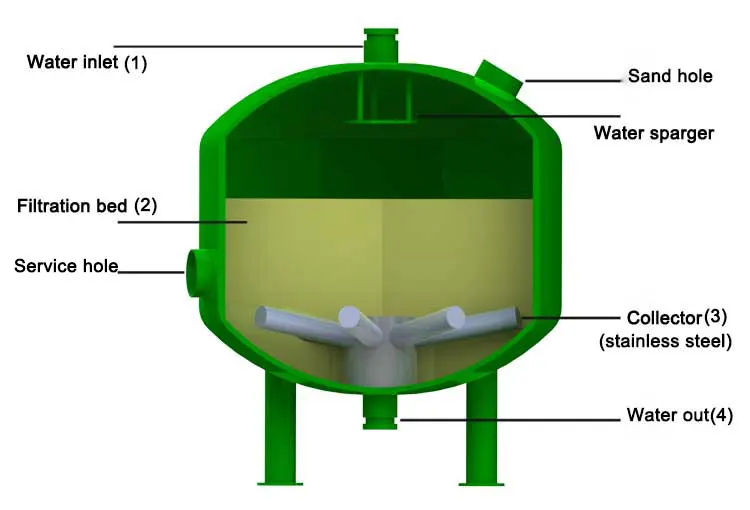

Working princinple

The Filtering Process

Filtering with media filters, also known as depth filtration, is done by filtering water through a thick layer of graded particles, called the filter bed. These particles can be sand, gravel or other granular materials. The filtration degree depends on the effective size of the bedding and the water velocity through the filter.

Raw water enters from the filter inlet (1) and percolates through the filter bed (2). Suspended materials come into contact and attach to the media particles. Clean water flows through the filtration nozzles (3) and out of the filter via the outlet valve (4).

The gradual dirt buildup in the filter bed causes an increase in the pressure differential across the filter and when it reaches its maximum design value, a cleaning process should be performed. In automatic media filter installations a pressure differential switch senses the pressure differential and when it reaches a preset value, the self cleaning process begins.

The Cleaning Process

Cleaning is done by backwashing; pressurized water flows in reverse direction – from the nozzles upwards, causing suspension of the filter bed, thus releasing the suspended matter from the bedding. The dirt particles are then washed out of the filter through the back-flush valve. In automatic media filters installations the cleaning process is done by the system's controller. When the pressure differential switch senses that the differential pressure across the system reached a pre-set value, a signal is sent to the flushing controller and the self cleaning process begins.

The Control System

CDFS supplies several control systems for its sand filters such as Electrical Control Boards, Programmable Logic Controllers (PLCs) for supporting any size of media filters installation.

CDFS control systems starts the self-cleaning cycle under any one of the following conditions:

1. Receiving a signal from the Pressure Differential Switch

2. Time interval parameter set at the control system

3. Manual Start

Sand filter specification sheet

| Model | Vessels QTY |

Max.flow (agri.) |

Max.flow (indus.) |

Min. pressure | Max. pressure | Backwashing flow |

Water in/out (mm/inch) |

| DMF24-2-A | 2 | 30 | 22 | 0.2 | 1.0 | 15 | 80 / 3 |

| DMF24-3-A | 3 | 45 | 33 | 0.2 | 1.0 | 19 | 80 / 3 |

| DMF28-2-A | 2 | 60 | 30 | 0.2 | 1.0 | 30 | 100 / 4 |

| DMF28-3-A | 3 | 90 | 45 | 0.2 | 1.0 | 50 | 100 / 4 |

| DMF32-2-A | 2 | 75 | 40 | 0.2 | 1.0 | 35 | 100 / 4 |

| DMF32-3-A | 3 | 115 | 60 | 0.2 | 1.0 | 50 | 150 / 6 |

| DMF36-2-A | 2 | 80 | 70 | 0.2 | 1.0 | 40 | 100 / 4 |

| DMF36-3-A | 3 | 120 | 105 | 0.2 | 1.0 | 50 | 150 / 6 |

| DMF48-2-A | 2 | 160 | 100 | 0.2 | 1.0 | 80 | 150 / 6 |

| DMF48-3-A | 3 | 240 | 150 | 0.2 | 1.0 | 80 | 200 / |

Remark: 1. Agri - agricultral irigation, indus. -industrial.

2. The flow is different when used for irrigation and industrial

Sand filter dimensions

| Model | D | L | W | H1 | H2 | H3 | h (agri.) |

h (Indus.) |

| DMF24-2-A | 600 | 1330 | 630 | 130 | 1215 | 1450 | 400 | 600 |

| DMF24-3-A | 600 | 2030 | 630 | 130 | 1215 | 1450 | 400 | 600 |

| DMF28-2-A | 700 | 1520 | 720 | 140 | 1305 | 1580 | 400 | 600 |

| DMF28-3-A | 700 | 2320 | 720 | 140 | 1305 | 1580 | 400 | 600 |

| DMF32-2-A | 800 | 1720 | 820 | 140 | 1345 | 1620 | 400 | 600 |

| DMF32-3-A | 800 | 2620 | 820 | 170 | 1395 | 1695 | 400 | 600 |

| DMF36-2-A | 900 | 1920 | 920 | 140 | 1385 | 1660 | 400 | 600 |

| DMF36-3-A | 900 | 2920 | 920 | 170 | 1440 | 1740 | 400 | 600 |

| DMF48-2-A | 1200 | 2620 | 1220 | 170 | 1593 | 1925 | 400 | 600 |

| DMF48-3-A | 1200 | 4020 | 1220 | 200 | 1648 | 2005 | 400 | 600 |

| Payment & Shipping |

|

PAYMENT: Standard payment terms: 30% deposit, the balance before shipping after inspection. (LC/DA/DP PAYPAL WESTERN UNION) |

SHIPPING: Delivery time: production time pls confirm with salesman for detail requirement Packing: we can do according to your requirement. |

| Engineering case |

| Company Profile |

Hunan Dawning Filter System Technology Co., Ltd. have been specialized in manufacturing and marketing water filter systems since 2002.

The filters are automatic back washing filter, self cleaning filter,sand media filter, disc filter and so on. We could provide efficient,stable solutions for irrigation and industrial water treatment.

Our products are widely used in construction, steel, electricity, petrochemical, metallurgical, pharmaceutical, paper, automotive, hotels, municipal and other major industries.

Our products have been exported to hundreds of countries and regions such as America, Canada, Chile, Australia, Italy, India, Singapore,Korea,etc. We owned 9 patents and adopted the ISO9001 and CE.

Our team are professional and always here to support you!

| CTW Showroom |

| Customer Visit |

| FAQ |

Q: Where is your factory?

A:Changsha city, Hunan province, China??

Q: How about the delivery time?

A: Usually 10-15 days for standard model.

Q:Does the filter operated automatically?

A:Yes.Automatic backwash by differential pressure/ time.

Q:Can you accept OEM?

A:Yes.We could do OEM for you.

?

Q: Do you have a certification?

A: Yes. we have ISO / CE certificate and certificate of patent

Q: Can we choose the color of filter housing?

A: Yes. Blue/green/red or others.

Q:How is the installation of filter?

A: Shipping in skid. Just connect the flanges of water in/out and drain out.

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com