Shanghai factory direct sales of all kinds food and daily necessities plastic roll film vertical packaging

- Категория: Multi-Function Packaging Machines >>>

- Поставщик: Shanghai,Tops,Group,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 8318.35 $* | 8734.40 $* |

| Aug-18-2025 | 8248.35 $* | 8660.94 $* |

| Jul-18-2025 | 6920.18 $* | 7266.63 $* |

| Jun-18-2025 | 8108.46 $* | 8513.99 $* |

| May-18-2025 | 7060.92 $* | 7413.85 $* |

| Apr-18-2025 | 7969.83 $* | 8367.67 $* |

| Mar-18-2025 | 7899.83 $* | 8294.26 $* |

| Feb-18-2025 | 7829.77 $* | 8220.35 $* |

| Jan-18-2025 | 7759.0 $* | 8147.31 $* |

Характеристики

Product Description&Applications

1. General Description

Our TP-GF-V Series Granule Packing Machine is special designed to packing granules. It is widely used in food, chemical, medicine industry. It is your best solution for packaging products like salt, suger, rice, wheat, soyabean, peanut, cocoa nut, almoud,

olive, sunflower seed and other chemical particals like that.

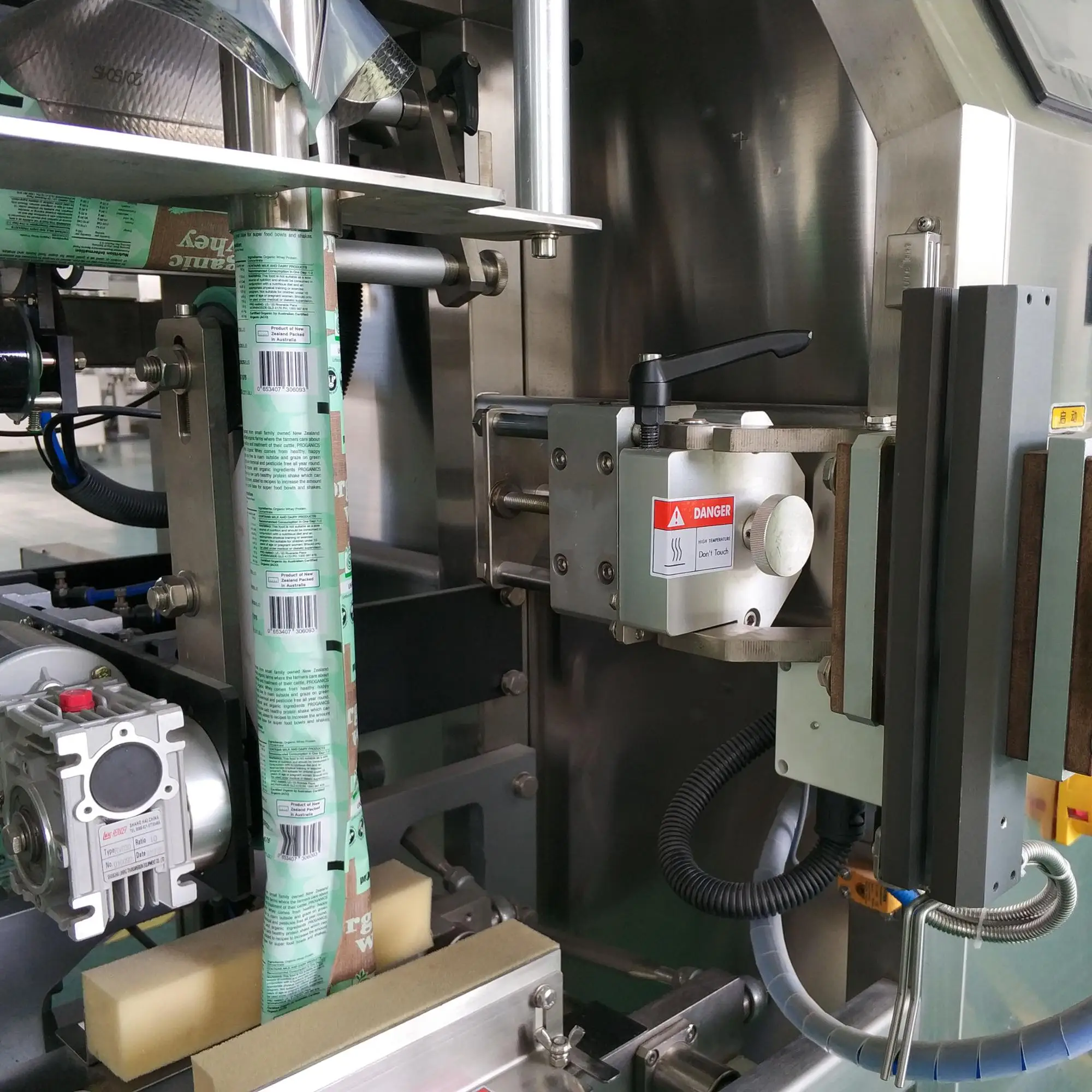

2. Working Principle

TP-GF-V Series Granule Packing Machine is a multi-functional packing machine.It works in following steps:

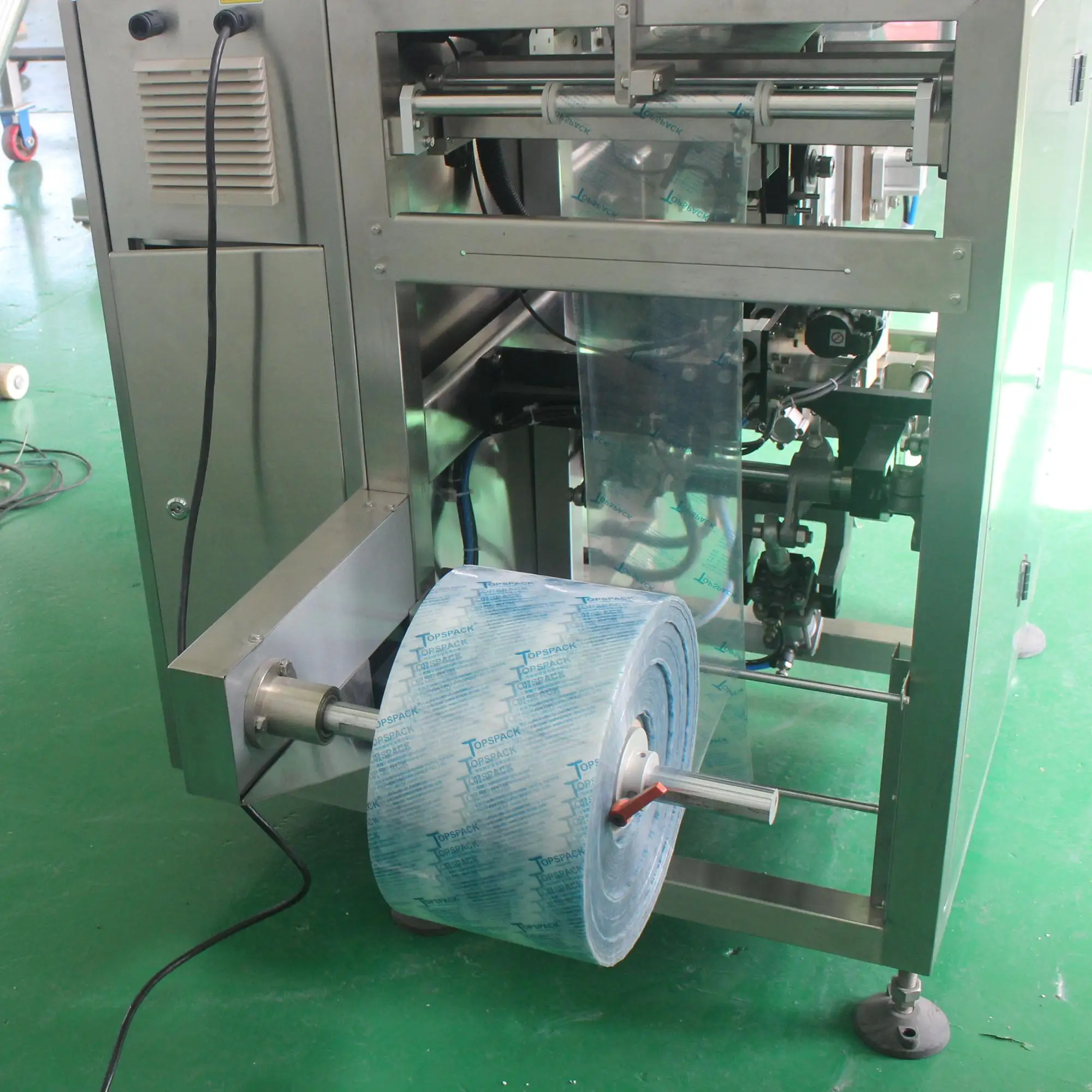

a. put in plastic film and material

b. forming a plastic sachet / bag

c. printing date

d. filling in the granules

e. sealing sachet /bag

The plastic sachet can be sealed as you required.

Our TP-GF-V Series Granule Packing Machine is special designed to packing granules. It is widely used in food, chemical, medicine industry. It is your best solution for packaging products like salt, suger, rice, wheat, soyabean, peanut, cocoa nut, almoud,

olive, sunflower seed and other chemical particals like that.

2. Working Principle

TP-GF-V Series Granule Packing Machine is a multi-functional packing machine.It works in following steps:

a. put in plastic film and material

b. forming a plastic sachet / bag

c. printing date

d. filling in the granules

e. sealing sachet /bag

The plastic sachet can be sealed as you required.

Liquid/paste type: detergent,e, soy sauce, rice vinegar, fruit juice, beverage, tomato sauce, peanut butter, jam, chili sauce,

bean paste,etc.

Block material: bean curd cake, fish, eggs, candy, red jujube, cereal, chocolate, biscuit, peanut, etc.

Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer,etc.

Powder type: milk powder, glucose, monosodium glutamate, seasoning, washing powder, chemical materials, fine white sugar, pesticide, fertilizer, etc. Class of pickles, pickled cabbage, kimchi, pickled cabbage, radish, etc.

bean paste,etc.

Block material: bean curd cake, fish, eggs, candy, red jujube, cereal, chocolate, biscuit, peanut, etc.

Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer,etc.

Powder type: milk powder, glucose, monosodium glutamate, seasoning, washing powder, chemical materials, fine white sugar, pesticide, fertilizer, etc. Class of pickles, pickled cabbage, kimchi, pickled cabbage, radish, etc.

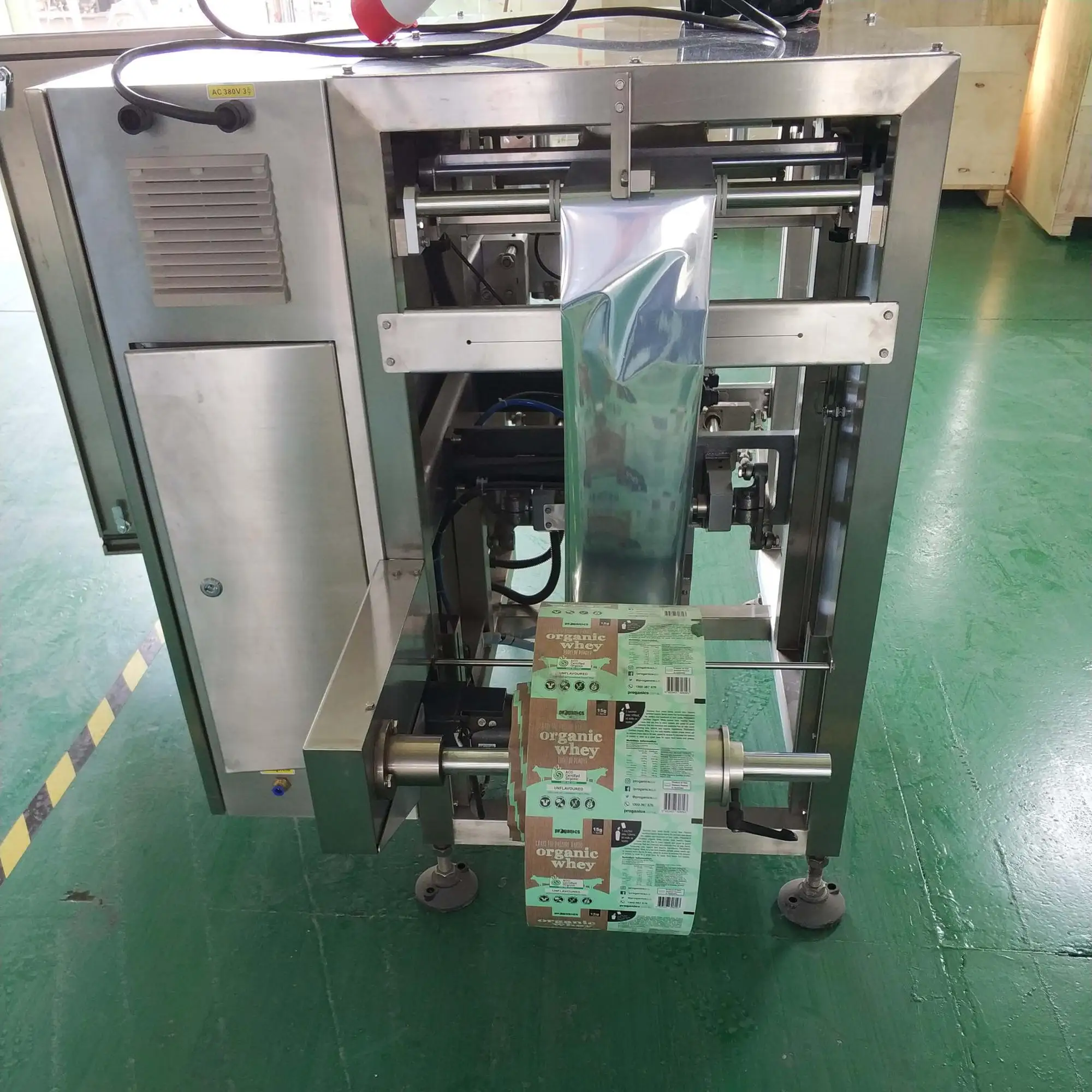

Bag Type

Various bag types are available:All type of heat sealable performed side seal bags,block bottom bags,zip-lock recloseable bags,stand-up pouch with or without spout,paper bags,etc.

Features &Specificaton

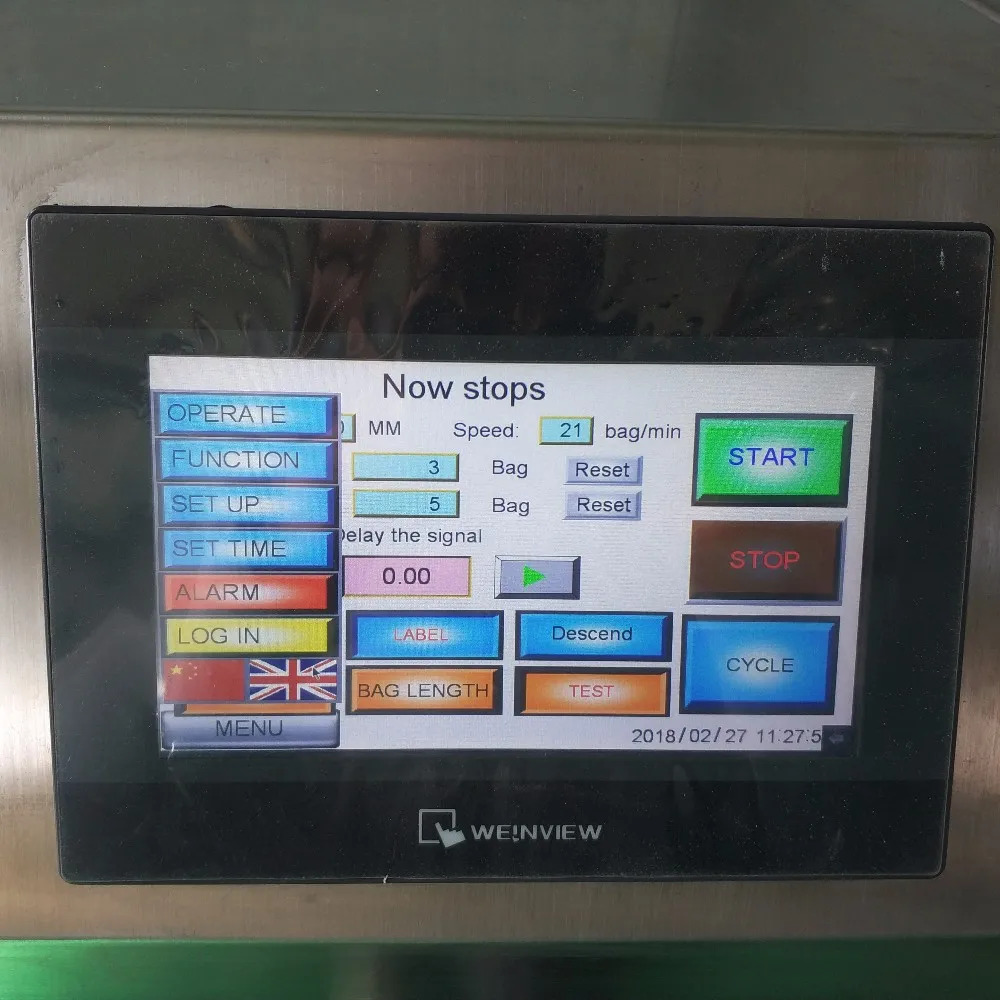

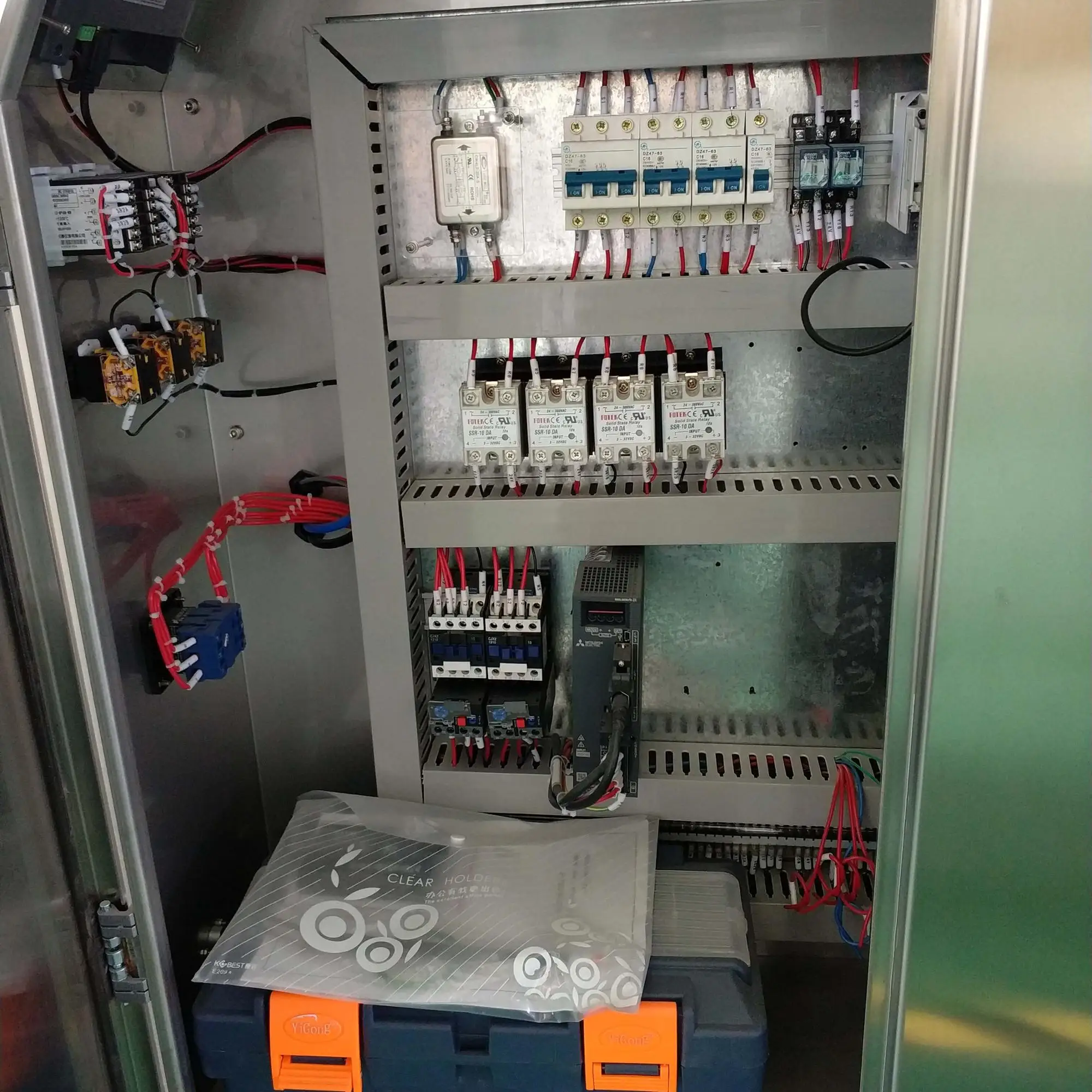

* Easy to operate,adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly.

* Frequency conversion adjusts the speed: this machine uses frequency conversion equipment, can be adjusted

within the range according to the needs of reality in production.

within the range according to the needs of reality in production.

* Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

* The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of clips, easily operate, and save time.

* The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification.

* Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food.

Model | Measuring cup type |

Pouch size | (W):30-100mm (L):30-120mm |

Speed | 40-60(bag/min) |

Weight | 190kg |

Voltage | 380V 3phase 50HZ/60HZ (could be 220v) |

Total power | 0.72KW |

Dimension | 625x751x1558mm |

The first turntable (eight stations):

①. The first station: give the bag; put the prefabricated bag on the bag bin, the bag can move up and down, when the bag falls, use the suction cup to take the bag, when it rises, use the two suction cups of the robotic arm to turn the bag Workbench manipulator claw.

②, The second station: open the zipper

③. The third station: open the bag; use two suction cups on the upper and lower parts of the bag to open the bag.

④. The fourth station: unloading

⑤, The fifth station: poke the material

⑥ The sixthstation: the material is stationary

⑦. The seventh station: double-sided constant temperature sealing 1 (straight pattern)

⑧, The eighth station: double-sided constant temperature sealing 2 (net pattern)

The first turntable (eight stations):

①. The first station: give the bag; put the prefabricated bag on the bag bin, the bag can move up and down, when the bag falls, use the suction cup to take the bag, when it rises, use the two suction cups of the robotic arm to turn the bag Workbench manipulator claw.

②, The second station: open the zipper

③. The third station: open the bag; use two suction cups on the upper and lower parts of the bag to open the bag.

④. The fourth station: unloading

⑤, The fifth station: poke the material

⑥ The sixthstation: the material is stationary

⑦. The seventh station: double-sided constant temperature sealing 1 (straight pattern)

⑧, The eighth station: double-sided constant temperature sealing 2 (net pattern)

Shanghai Tops Group Co., Ltd is professional manufacturer for powder and granular,liquid packaging systems.We specialize in the

fields of designing, manufacturing, supporting and servicing a complete line of machinery for different kinds of powder and granular,liquid products, Our main target of working is to offer the products which are related to the food industry, agriculture industry, chemical industry, and pharmacy field and more.

fields of designing, manufacturing, supporting and servicing a complete line of machinery for different kinds of powder and granular,liquid products, Our main target of working is to offer the products which are related to the food industry, agriculture industry, chemical industry, and pharmacy field and more.

Похожие товары

Автоматическая машина для упаковки зерна JKPACK

US $6000-$6800

Новая высококачественная упаковочная машина для мешков в саше, на молнии

US $20000-$500000

Автоматическая упаковочная машина для муки с открытым горлом

US $2000-$4000