Полые стены PE HDPE спиральная обмотка трубы шланг установка для

- Категория: Pipe Making Machinery >>>

- Поставщик: Cissco,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.39 $* | 0.73 $* |

| Aug-19-2025 | 0.63 $* | 0.84 $* |

| Jul-19-2025 | 0.26 $* | 0.56 $* |

| Jun-19-2025 | 0.8 $* | 0.61 $* |

| May-19-2025 | 0.35 $* | 0.24 $* |

| Apr-19-2025 | 0.60 $* | 0.74 $* |

| Mar-19-2025 | 0.78 $* | 0.55 $* |

| Feb-19-2025 | 0.95 $* | 0.19 $* |

| Jan-19-2025 | 0.89 $* | 0.57 $* |

Характеристики

HDPE Winding Pipe Production Machine

1. Krah Pipes

Since generations the mankind is busy by transporting water/sewer or any other liquids from one point to another point. The challenge was always to assure a conveyance system without fails and leakage. Most pipe failures were occurring on the joints through corrosion or cracks on the rigid inflexible pipe material.

Over the last decades, the inherent weaknesses of concrete, clay, ductile, PVC and steel caused tremendous problems in existing water supply, sewer pipes systems, as they tend to be brittle or are too sensitive for aggressive chemicals and soil conditions. Leakages have become a common occurrence worldwide in water, sewer and other large diameter pipe applications. In addition, they have an unprofitable relationship between cost and benefit due to short life time and high maintenance costs.

Krah Pipes are made out different grades of pure Polyethylene or Polypropylene who are providing superior properties against corrosion, leakage, pipe displacement and ex-infiltration. In addition to the permanent solution that lasts through generations, the Krah piping system is able to provide a sustainable, environment friendly and economical solution with its wide-ranging fields of applications, f.e. water supply, sewer systems, drainage, storm water management, sea outfalls/intake, manholes and reservoirs.

In order to meet the demand of the at least 100 years leak free, sustainable and flexible pipe system, Krah Pipes are produced with an integrated electro fusion joint system, which assures a melting of the pipes to a homogenous and monolithic pipe system.

Krah Pipes can be produced from the following thermoplastic materials:

- High density polyethylene (PE80 and PE100))

- Polypropylene – random (PP-R, PP-B)

- Polypropylene – homo (PP-H)

- Flame retardant polypropylene (PP-S)

- Other materials can be used after prior acceptance of the producer and a third party for quality control.

2. Advantages of Krah Pipes

Krah Pipes are made from HD-PE100 (acc. to DIN16961, EN13476, ASTM F894, ISO9969 and other intl. standards) are produced with an integrated electro fusion joint socket and spigot. The pipe is completely helically extruded with profiles or solid wall, tailor made for any kind of application within the standards. The pipes have no welding seams or any weak points and are completely monolithic made from high density PE100. There is no recycled mixed material used, to assure an excellent quality of the pipes which is assuring the service cycle of minimum 100 years.

The Electro Fusion jointing system by Krah according to the DVS Rules assures a homogenous, leak-free and flexible pipe system, without any weak points on the joints. The electro fusion welding process is an optimized process to be used directly in the tranches with very quick welding time under consideration of welding factors. The effect is that the pipe system in the soil is even under heavy loads or seismic movements flexible and without cracks, breaks or displacement appearing. The pipe system will continue to provide service and will not break!

The pipes are also lightweight with the required wall thickness of the waterway s1 according to the standard and can be adjusted for any kind of internal and/or outer pressure. This is a cost saving matter to avoid the usage of overdesigned pipes according to the application requirements.

The pipe system will provide service for more than 100 years without any leakage, break, cracks or displacement. The material is UV resistant and also very environmentally friendly.

Leak free: It’s preventing pollution of the environment with the sewer

Pipe material does not interact chemically with the soil, so it’s absolutely environmentally friendly and can be recycled to 100% as well.

No blockages will appear, no bacteria or anything can find a hold on the pipe due to its smooth antibacterial inner surface.

The bright color of the inner surface makes the pipe system inspection-friendly

No heavy lifting equipment is needed to install the pipes, lifting with simple excavators is possible and therefore there is no more dredging work necessary, which is more expensive during the construction work. In a bigger city, it is no longer necessary to close all lanes of the road for the pipe installation work.

Quick installation, as you have seen at the job sites will reduce the costs for construction significantly.

The pipe system will behave like our veins, monolithic, homogenous, flexible and leak free for 100 years!

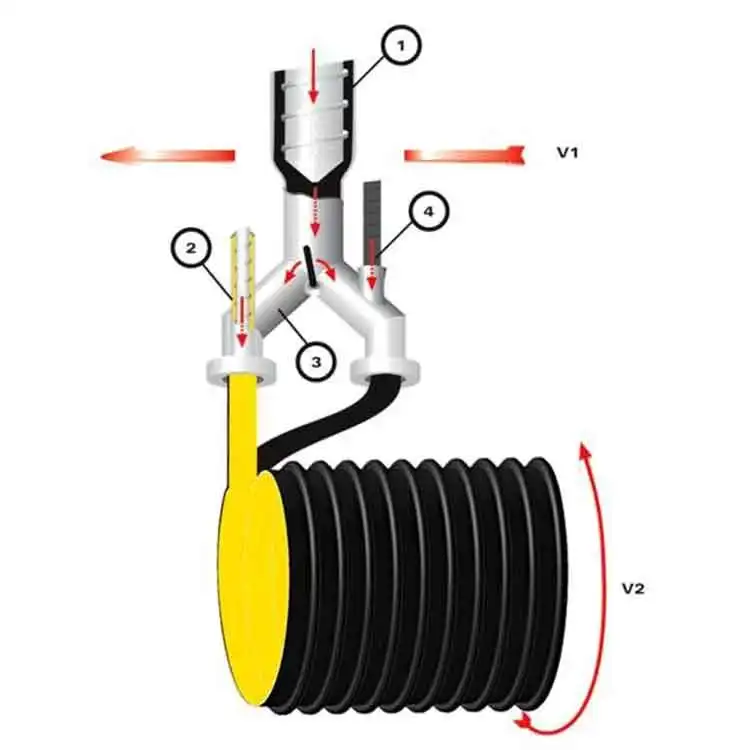

3. Configuration of Krah Pipes Production Line

| No. | Name | Qty |

| I | Mean production line | 1 set |

| 1 | Extrusion system | 1 set |

| 2 | Electrical apparatus control system | 1 set |

| 3 | Extruder trolley | 1 set |

| 4 | Extrusion passageway and mould | 1 set |

| 5 | Corrugated pipe delivery device | 1 set |

| 6 | Gas heating system and infrared heating system | 1 set |

| 7 | Moving winding platform system | 1 set |

| 8 | Cutting cooling stage | 1 set |

| 9 | Demoulding stage | 1 set |

| 10 | Manual Patching Unit | 1 set |

| 11 | Wire forming machine | 1 set |

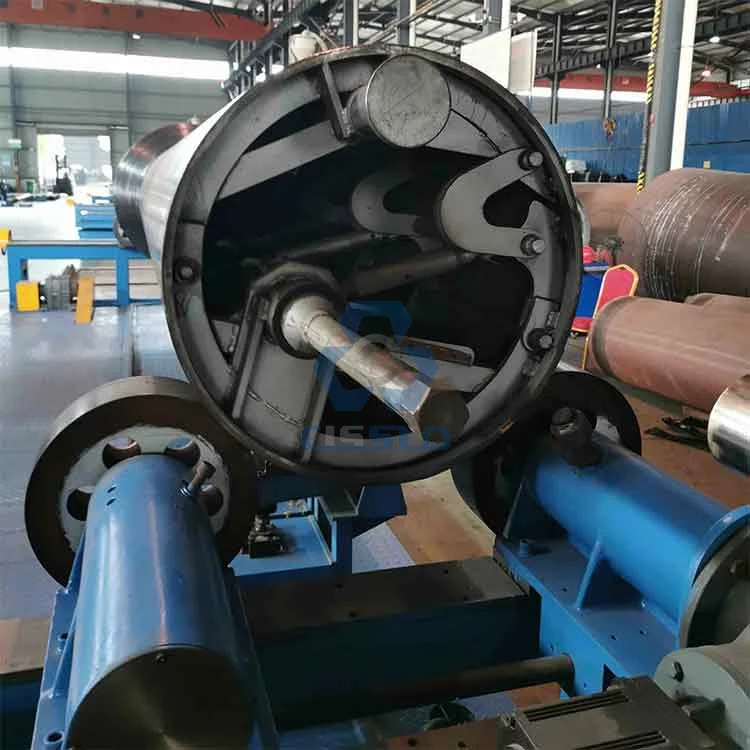

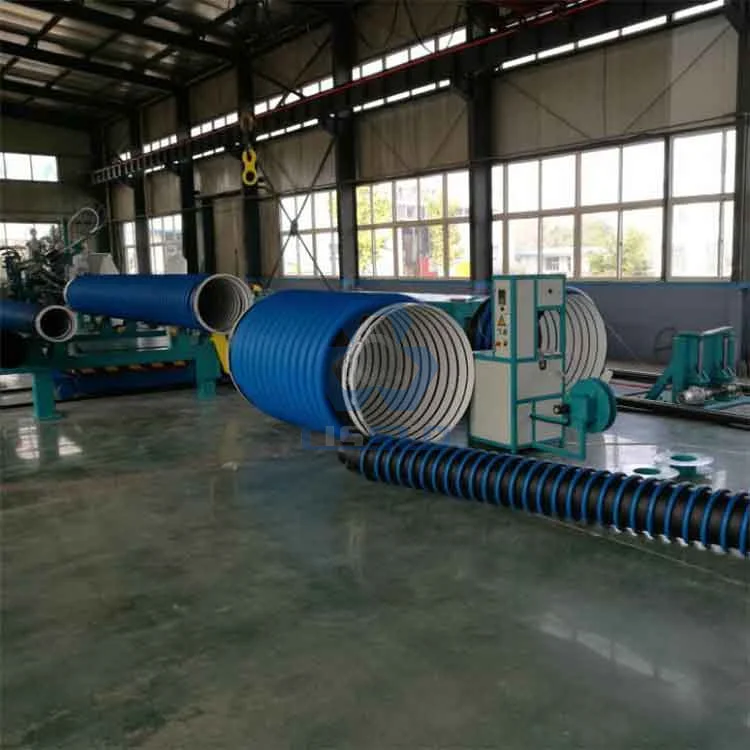

4. Photos of Krah Pipes Production Line

1. We design, engineer and manufacture and customized the extrusion line.

2. Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

3. Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

4. Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.

CissCo Machinery Co., has been engineering and manufacturing a series of EXTRUSION MACHINERY for more than 20 years and has thus acquired an extensive expertise in the supply of manufacturing machinery; having based ourselves on the features demanded by large companies in more than 30 countries.

Comparing with the low price low quality machine, please note our strong advantages:

1. 20 Years Experiences;

2. European Latest Technology;

3. Easy to Operate, Stable Performance, Good Quality Products, Low Production Cost;

4. Quicker Production Speed, Big Output;

5. Good Material and Well-Known Brand Electrical Parts;

6. Beautiful Appearance;

7. Free Training for Technical Process, Formula and Know-How;

8. Full Time and High Level After-Sale Services.

- What's the pressure class of pipe made by your machine?

- Less than 1MPA;

- What's the material of this kind of pipe?

- HDPE;

- PP;

- Masterbatch;

- Wire

- What's the pipe diameter range of pipe made by your machine?

- 100-4000 inch.

- What's your delivery time of machine?

- 3 months after down payment.

- What's your machine guarantee time?

- 12 months after shipping.

- How many years experiences do you have in this machine manufacturing?

- Around 20 years.

l Contactor: Mr. Louies Liu

l Skype: louies.cissco

l Cellphone/Whatsapp/WeChat: +86 18917527205

l Web: www.cisscomachinery.com

l Add: No. 58, New Jinqiao Road, Pudong, Shanghai, China