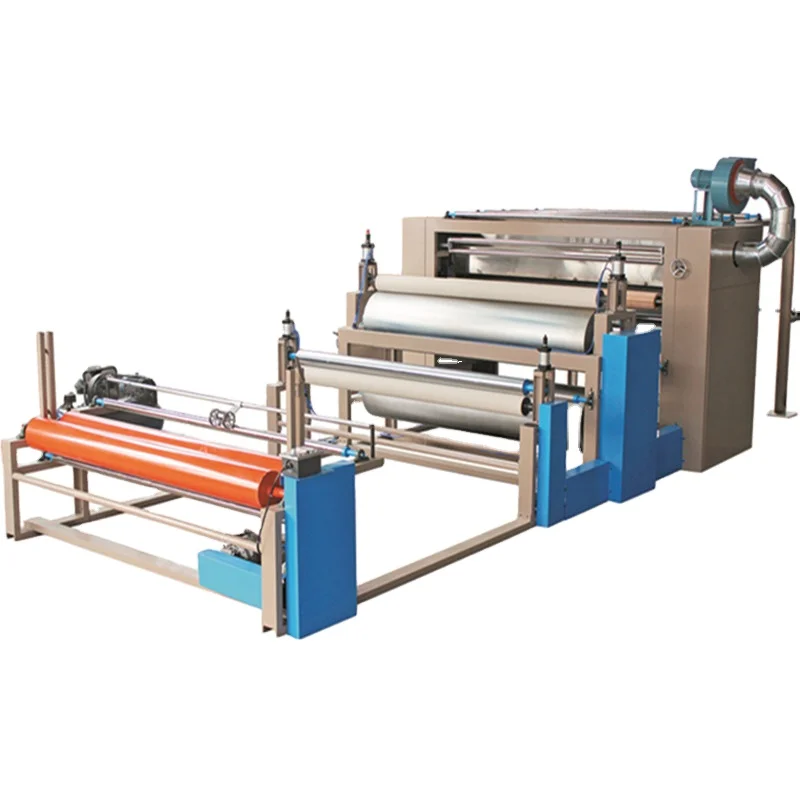

Машина для ламинирования пламени автомобильных

- Категория: Other Textile Machines >>>

- Поставщик: Jiangsu,Kuntai,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 19040.66 $* | 19992.62 $* |

| Aug-19-2025 | 18880.2 $* | 19824.10 $* |

| Jul-19-2025 | 15840.61 $* | 16632.76 $* |

| Jun-19-2025 | 18560.56 $* | 19488.94 $* |

| May-19-2025 | 16160.10 $* | 16968.91 $* |

| Apr-19-2025 | 18240.81 $* | 19152.94 $* |

| Mar-19-2025 | 18080.69 $* | 18984.86 $* |

| Feb-19-2025 | 17920.62 $* | 18816.50 $* |

| Jan-19-2025 | 17760.66 $* | 18648.33 $* |

Характеристики

Flame Laminating Machine for car seats/carpet

it is used for:

To laminate foam/sponge with woven or non woven fabrics, knitted, natural or synthetic fabrics, velvet, plush, polar fleece, corduroy, leathter, synthetic leather, PVC, etc.

Automotive industry ( car interiors, car seats)

Furniture industry ( office chairs, sofas, babies items, stuffings)

Footwear industry

Garment industry

Household cleaning products -PU-fibre scourers

Heat insulation - sound absorption, etc.

Working Process:

- Flame lamination is a process that adheres material to one side of the fire retardant foam or EVA.

- Pass the foam or EVA over a flame produced by a flare roller, creating a thin layer of sticky stuff on the surface of one side of the foam or EVA.

- Then, quickly press the material against the sticky stuff of the foam or EVA.

Features:

- Gas Type: Natural Gas or Liquefied Gas.

- The water cooling system well enhances the lamination effect.

- The air exhaust diaphragm will exhaust the odor.

- Fabric spreading device is installed to make the laminated material smooth and neat.

- The strength of the bonding depends on the material and the foam or EVA selected and the processing conditions.

- With high integrity and long term adhesive durability, the laminated materials touch well and is dry washable.

Edge tracker, tensionless fabric unwinding device, stamping device and other auxiliary equipment can be optionally installed.

Heat source | industrial use of electricity |

Width of roll | 2100mm |

Width of finished product | 1900mm |

Mechanical speed | 20 - 45m / min |

Installed capacity | about 10KVA |

Dimensions | 13000 x 2500 x 2200mm |

RFQ

1,Historical precipitation technological innovation.

32 years of rich experience for various industries to provide composite cutting equipment, fabric stamping equipment and other industry solutions.

2,Globalization after sales

Covering 5 continents with over 60 countries complete after sales service, no matter where you are, kuntai's service time is at your side?

3,Industry-specific customization

A strong team of engineers will make the best one-to-one customization for your product requirements to maximize the advantages of your product equipment.

4,Strong technical support.

The technical support of southeast university, the practice training of German engineers, and the team of dozens of experts are the technical guarantee for you to purchase the machine in kuntai.

5,High quality standards.

The IOS system certification, the eu CE certification and the us UL certification are the quality assurance for us. CTPM refined management is our guideline for high quality standards.

Click below “send” pls,best price is ready for you !