Технический гидравлический листогибочный станок da66t с ЧПУ применяется на Производственном заводе

- Категория: Press Brake >>>

- Поставщик: Nanjing,Bosslaser,CNC,Technology,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 9877.80 $* | 10371.61 $* |

| Aug-17-2025 | 9794.8 $* | 10284.35 $* |

| Jul-17-2025 | 8217.62 $* | 8628.83 $* |

| Jun-17-2025 | 9628.50 $* | 10109.72 $* |

| May-17-2025 | 8383.60 $* | 8802.28 $* |

| Apr-17-2025 | 9462.30 $* | 9935.28 $* |

| Mar-17-2025 | 9379.34 $* | 9848.57 $* |

| Feb-17-2025 | 9296.6 $* | 9761.26 $* |

| Jan-17-2025 | 9213.22 $* | 9674.76 $* |

Характеристики

Bossor Laser Technology Co., Ltd

Anhui Bossor Laser Technology Co., Ltd. is one of the high-end laser processing equipment manufacturers, specializing in laser cutting equipment and bend-ing machine and other sheet metal equipment research and development, production and sales.

Bossor laser is committed to technology research and development. The company has modern production plants, equipped with advanced processing ma-chine tools in Germany and Spain. The company's production is based on ISO9001 quality control system, ISO14001 environmental management system, and ISO18001 occupational health and safety management system to ensure the performance and quality of products. Several product series have obtained the EU CE certification system.

In order to better serve customers, Bossor laser has established after-sales service system all over the world and has dozens of overseas agents to provide a full range of metal cutting application solutions for customers in different industries, so that the company's products and manufacturing processes in various industries can achieve seamless docking.

Bossor laser, help China intelligent manufacturing, create world quality, serve wold customers!

Bossor laser is committed to technology research and development. The company has modern production plants, equipped with advanced processing ma-chine tools in Germany and Spain. The company's production is based on ISO9001 quality control system, ISO14001 environmental management system, and ISO18001 occupational health and safety management system to ensure the performance and quality of products. Several product series have obtained the EU CE certification system.

In order to better serve customers, Bossor laser has established after-sales service system all over the world and has dozens of overseas agents to provide a full range of metal cutting application solutions for customers in different industries, so that the company's products and manufacturing processes in various industries can achieve seamless docking.

Bossor laser, help China intelligent manufacturing, create world quality, serve wold customers!

Product Description

DA66T 6+1 axis Hydraulic Press Brake

New EU streamlined design

The whole frame of the press brake adopt integrated welding, and by tempering to eliminate the internal stress.

The press brake frame adopt shot blast to remove rust and sprayed with anti-rust treatment.

The frame is formed by the imported CNC three-dimensional machining center in one process, which ensures the parallelism and verticality of each mounting surface.

The controller can control the Y1 and Y2 axes (Y1 controls the left cylinder and Y2 controls the right cylinder) to ensure the

synchronous movement of the ram.

Quiet speed waiting and fast down, (about 25 decibels), low noise during pressing and return (the pressure in the hydraulic system is the closed loop control of the servo main motor).

The main oil pump does not apply work under the drive of the servo main motor, and the energy consumption is 60% lower than that of the general CNC press brake machine.

The machine oil temperature is stable, which extending the service life of various components of the hydraulic system.

More technical innovations to ensure the quality of bending, and powerful, easy to operate.

The press brake adopt the latest high-frequency hydraulic control technology, which is faster, more efficient and more stable.

The best parameter ratio, the optimal core configuration, the performance is stable, the operation is more convenient, and the bending of various workpieces in complex shape can be realized.

The whole frame of the press brake adopt integrated welding, and by tempering to eliminate the internal stress.

The press brake frame adopt shot blast to remove rust and sprayed with anti-rust treatment.

The frame is formed by the imported CNC three-dimensional machining center in one process, which ensures the parallelism and verticality of each mounting surface.

The controller can control the Y1 and Y2 axes (Y1 controls the left cylinder and Y2 controls the right cylinder) to ensure the

synchronous movement of the ram.

Quiet speed waiting and fast down, (about 25 decibels), low noise during pressing and return (the pressure in the hydraulic system is the closed loop control of the servo main motor).

The main oil pump does not apply work under the drive of the servo main motor, and the energy consumption is 60% lower than that of the general CNC press brake machine.

The machine oil temperature is stable, which extending the service life of various components of the hydraulic system.

More technical innovations to ensure the quality of bending, and powerful, easy to operate.

The press brake adopt the latest high-frequency hydraulic control technology, which is faster, more efficient and more stable.

The best parameter ratio, the optimal core configuration, the performance is stable, the operation is more convenient, and the bending of various workpieces in complex shape can be realized.

DA66T Control Syatem

"2D graphical touch screen programming mode

3D visualisation in simulation and production

17″ high resolution colour TFT

Full Windows application suite

Delem Modusys compatibility (module scalability and adaptivity)

3D visualisation in simulation and production

17″ high resolution colour TFT

Full Windows application suite

Delem Modusys compatibility (module scalability and adaptivity)

USB, peripheral interfacing

User specific application support within the controllers multitasking environment

User specific application support within the controllers multitasking environment

Sensor bending & correction interface

Profile-TL offline software

Profile-TL offline software

Specification

No | item | Value | ||||||||||

100T/2500 | 100T/4000 | 125T/4000 | 160T/3200 | 300T/6000 | ||||||||

1 | CNC Control Axis | 3+1 axis (Y1, Y2, X + V Crowning) Optional R axis | ||||||||||

2 | Norminal force | 1000 | 1000 | 1250 | 1600 | 3000 | ||||||

3 | Bending length | 2500 | 4000 | 4000 | 3200 | 6000 | ||||||

4 | Table width | 140 | 140 | 140 | 140 | 140 | ||||||

5 | Machine weight | 8500 | 9600 | 9800 | 10200 | 24500 | ||||||

6 | Length | 2850 | 4550 | 4550 | 3550 | 6350 | ||||||

7 | Width | 2250 | 2250 | 2250 | 2250 | 2250 | ||||||

Height | 2450 | 2450 | 2480 | 2680 | 3200 | |||||||

Standard Equipment

Tooling

The standard top punch and dual-V bottom die are specially designed for bending sheet metals. More press brake toolings can be selected as per your practical use. Material and HRC47 degree values are marked on it

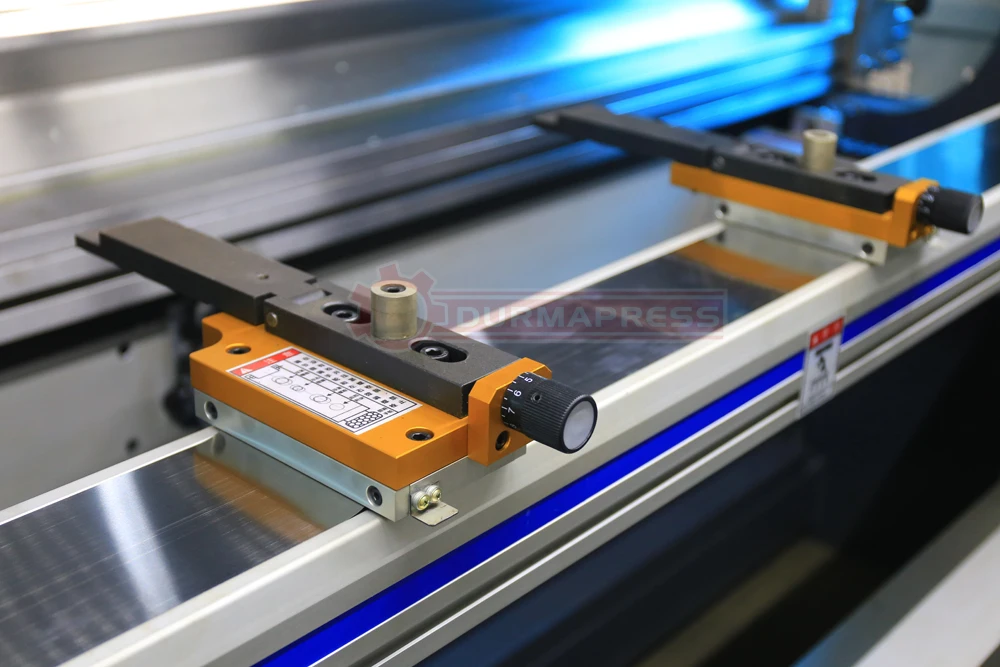

Two linear support

Front Suppotor with features of simple structure, powerful functions, can be adjusted up and down, or moved along the workbench in rightwards and leftwards

Fast Clamp

Standard double-V lower dies with different size and various shaped slots for choice, convenient for exchanging dies, capable for

bending regular plates, with high cost performance-ratio CNC double-V die workbench, convenient for installation of segmented dies.

bending regular plates, with high cost performance-ratio CNC double-V die workbench, convenient for installation of segmented dies.

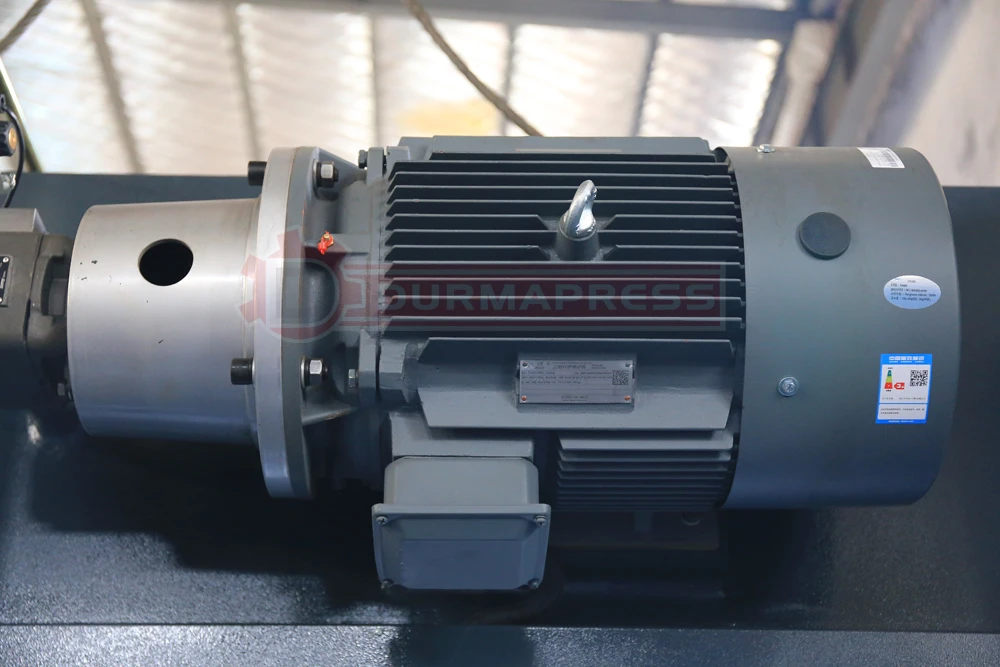

Siemens Motor

Compared to traditional stepper motors, the advantages of using servo motors include: improve the accuracy to ± 0.01mm, the noise decrease to 25 decibels, reduce energy consumption by 60%, consump 70% less

hydraulic oil and 30% higher efficiency.

hydraulic oil and 30% higher efficiency.

Rexroth Valve

Adopt Germany's Bosch Rexroth integrated structure of oil pump and hydraulic valve to ensure the bending accuracy.

Schneider Electronics

Our press brake adopt Schneider electrical components. The high quality electric parts can make the machine performing well even the electricity is not stable and customers can easily get the replacement anywhere in the world.

Electrical Crowning

Stopper Finger

Back Gauge

Packing & Delivery

* Packaging

Whole film packaging machine; Anti-collision package edge; Fumigation-free plywood wooden box and pallets with iron binding belt.* Shipping

We cooperate with SINOTRANS company whose experience in the ocean transportation will guarantee your machine safety. We also provide train transport, especially to Russia, Ukraine and other inland countries.Company Profile

Factory Profile

Our factory is located in Maanshan City, Anhui Province, established in 2014. Mainly engaged in production and design ofrectangular duct former and its related equipment, punching machine, folding machine, shearing machine, ironworker Since ourcompany started, we have accumulated a large amount of experiences for our domestic and overseas clients with best quality, service and solutions. And have established a very professional-young team to our client.

Nowadays Durmapress has grown to be a company which designs, manufactures and sells machines to customers all over the world, but we are still on the way to getting stronger and more professional. So, we are looking forward to cooperating, growing and developing with you sincerely.we believe your feedback is always important for us to grow. From such precious feedback, we know how we have been doing and how we could improve in the future. Please write us your comments, suggestions or questions and we will reply you soon.

Successful Case

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2019,sell to North America(20.00%),Southeast Asia(20.00%),Mid East(20.00%),Domestic Market(20.00%),South America(10.00%),Northern Europe(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

FIBER LASER CUTTING MACHINE,PRESS BRAKE,SHEARING MACHINE

4. why should you buy from us not from other suppliers?

In order to meet the special requirements of customers for products, Nanjing BOSSOR is willing to customize personalized products for you, so that customers can understand the professional services brought by sophisticated equipment.

We are based in Jiangsu, China, start from 2019,sell to North America(20.00%),Southeast Asia(20.00%),Mid East(20.00%),Domestic Market(20.00%),South America(10.00%),Northern Europe(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

FIBER LASER CUTTING MACHINE,PRESS BRAKE,SHEARING MACHINE

4. why should you buy from us not from other suppliers?

In order to meet the special requirements of customers for products, Nanjing BOSSOR is willing to customize personalized products for you, so that customers can understand the professional services brought by sophisticated equipment.

Related Products

Open type fiber laser cutitng machine

Board one exchange worktable fiber laser cutting machine