Квадратный стержень шлифовальное цилиндрическое оборудование/специальный фильтр/режущий оптический стеклянный круглый

- Категория: Internal Grinding Machines >>>

- Поставщик: Guangzhou Minder-Hightech Co., Ltd. [Guangdong,China]Guangzhou Minder-Hightech Co., Ltd. [Guangdong,China]Guangzhou Minder-Hightech Co., Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-15-2025 | 287037.34 $* | 292778.16 $* |

| Jul-15-2025 | 232793.52 $* | 237449.55 $* |

| Jun-15-2025 | 282516.43 $* | 288166.64 $* |

| May-15-2025 | 280256.95 $* | 285861.13 $* |

| Apr-15-2025 | 223753.99 $* | 228228.19 $* |

| Mar-15-2025 | 275736.71 $* | 281251.8 $* |

| Feb-15-2025 | 273476.98 $* | 278946.29 $* |

| Jan-15-2025 | 271216.26 $* | 276640.3 $* |

Характеристики

Brief introduction of J5090 automatic environmental protection inner circle slicer

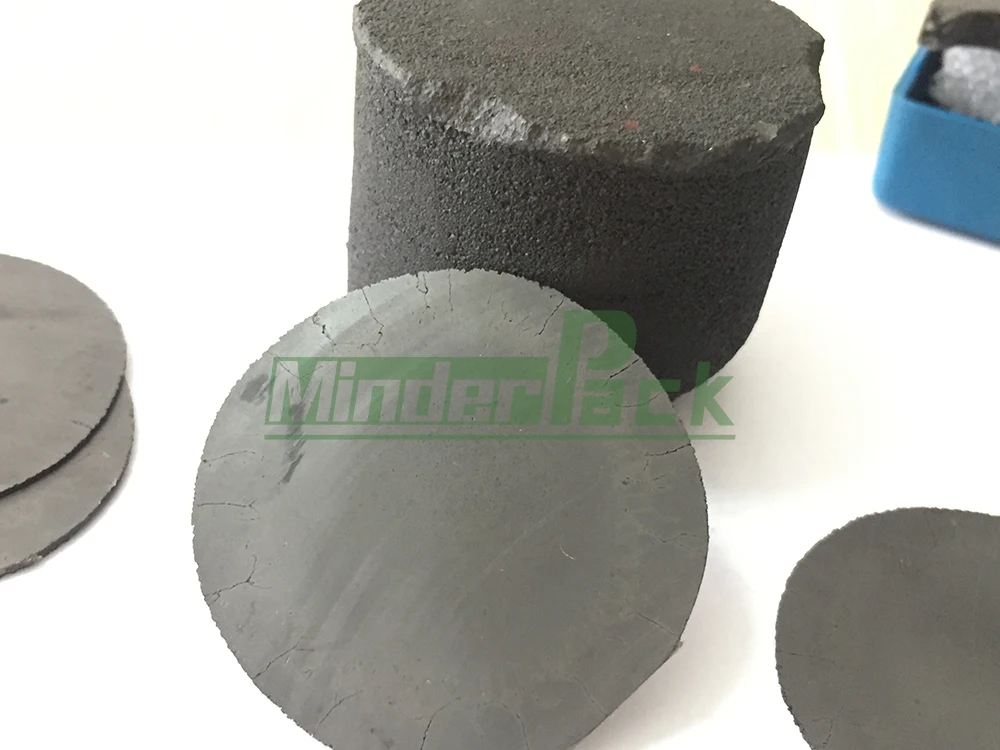

The J5090 automatic environmentally friendly internal circular slicer is a special equipment for cutting various optical glass, semiconductor, crystal, ceramics, neodymium iron boron magnetic materials. The circular internal blade diamond blade mounted on the spindle cutter rotates at high speed, and the worktable It is controlled by the computer to move horizontally and vertically to cut the material on the fixture into the required product

The automatic inner circle slicer is a special equipment for cutting various optical glass, semiconductors, crystals, gems, glass,

ceramics, graphite, neodymium iron boron magnetic materials, samarium cobalt, ferrite, etc.

The circular inner-blade diamond blade mounted on the spindle cutter rotates at high speed, and the worktable is controlled by the

computer to move horizontally and vertically to cut the material on the fixture into the desired product.

One worker can operate about 20 sets of automatic inner circle slicers at the same time.![]()

![]()

![]()

ceramics, graphite, neodymium iron boron magnetic materials, samarium cobalt, ferrite, etc.

The circular inner-blade diamond blade mounted on the spindle cutter rotates at high speed, and the worktable is controlled by the

computer to move horizontally and vertically to cut the material on the fixture into the desired product.

One worker can operate about 20 sets of automatic inner circle slicers at the same time.

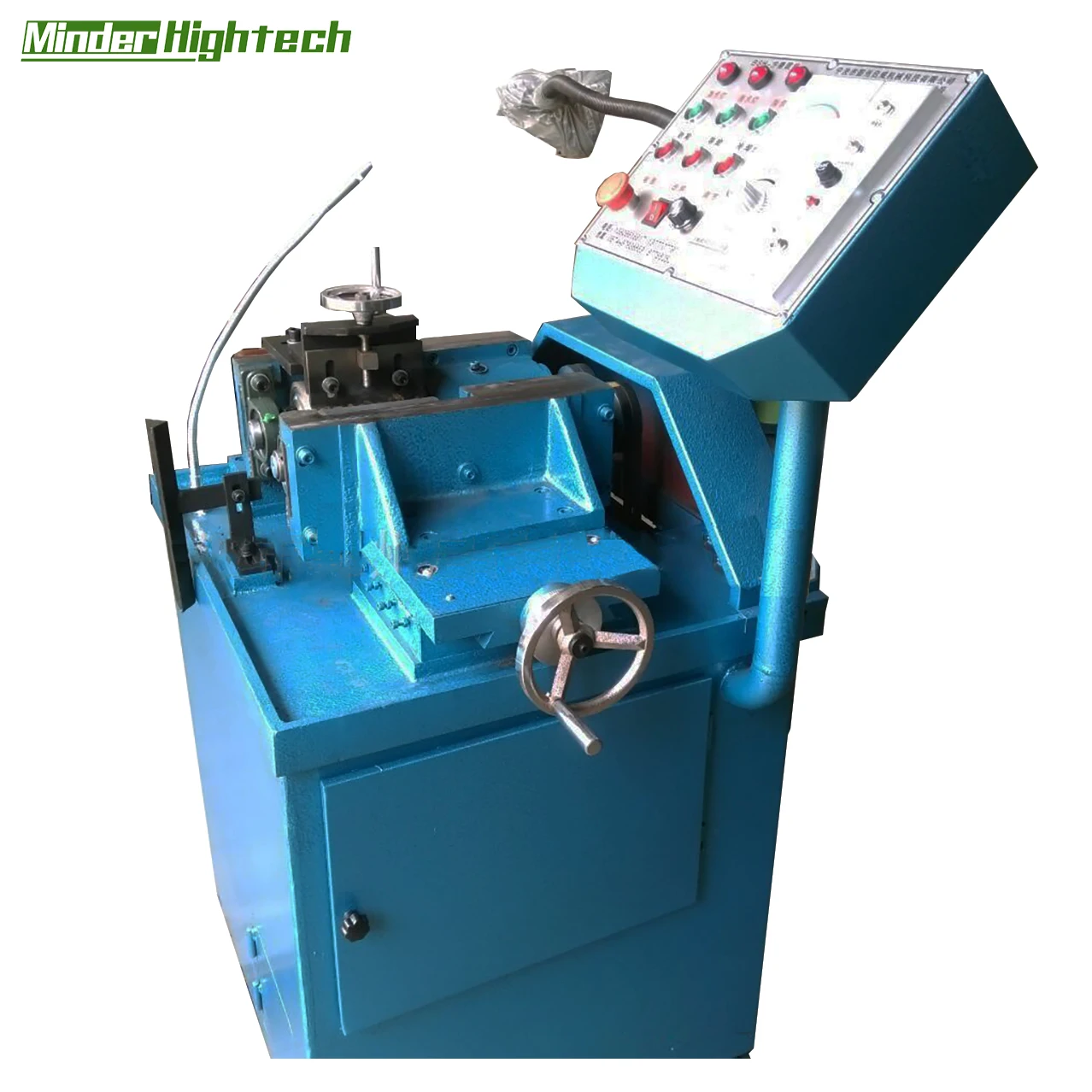

Square grinding is a special equipment for grinding small cylinders of neodymium iron boron magnetic materials, optical glass

rods, graphite rods, and ceramic rods. It uses a gold steel grinding wheel mounted on the main shaft and a guide wheel to rotate

in the positive direction to grind the small square bars into small cylinder.

There are two types of semi-automatic and full-automatic square grinding machines in our factory. One semi-automatic square

grinding machine can be operated by one worker, and one full-automatic square grinding machine can operate multiple machines at

the same time.![]()

![]()

![]()

rods, graphite rods, and ceramic rods. It uses a gold steel grinding wheel mounted on the main shaft and a guide wheel to rotate

in the positive direction to grind the small square bars into small cylinder.

There are two types of semi-automatic and full-automatic square grinding machines in our factory. One semi-automatic square

grinding machine can be operated by one worker, and one full-automatic square grinding machine can operate multiple machines at

the same time.

Product details

![]()

![]()

![]()

The main technical parameters | ||||

Maximum processing size(mm) | φ95 × 90 mm | |||

Cutting speed (㎝²/min) | 3-6((㎝²/min)) | |||

Balance deviation of sliced slices(mm) | ±0.005㎜ | |||

Slice thickness(mm) | ≥0.30 | |||

Tolerance range of sliced slice(mm) | ±0.015㎜ | |||

Horizontal stroke(mm) | 120㎜ | |||

Longitudinal stroke(mm) | 100㎜ | |||

Spindle electromechanical | 三相1.1kw | |||

Spindle speed (r/min) | 2800 | |||

Work fixture adjustment | Horizontal angle | ±45º | ||

Pitch angle | ±10º | |||

Vertical lift(mm) | 20 | |||

Cooling box volume(kg) | 50kg | |||

Bearing | Harbin Bearing | |||

power supply | 三相四线 50Hz 380V | |||

Dimensions(mm) | 1050 ×830 ×1500 | |||

equipment weight(kg) | approximately1000(kg) | |||

Specification

![]()

![]()

![]()

Max machining size(mm) | φ60 ×80 mm | |||

Cutting speed (㎝²/㎜) | 3-6(㎝²/㎜) | |||

Degree of balance sheets by cutting deviation(mm) | ±0.005㎜ | |||

Cutting film thickness(mm) | ≥0.30 | |||

The thin-cut tolerance (mm) | ±0.015㎜ | |||

Horizontal stroke(mm) | 120㎜ | |||

Longitudinal travel(mm) | 100㎜ | |||

Longitudinal degrees | 0-100Grid, each grid To 0.01,Each turn a lap in order to1㎜ | |||

Spindle Electrical | 3 Phase 380V 0.75kw | |||

Spindle Speed (r/min) | 3500Rev /min | |||

Adjust the amount of work table Horizontal angle | ±45º | |||

Pitch angle of elevation | ±10º | |||

Vertically(mm): | 24 | |||

Cooling tank capacity(kg) | 50kg | |||

Cooling tank motor | 3 Phase 380V 0.12kw 2780r/min | |||

Power | Three-phase four-wire 50Hz 380V | |||

Dimensions(mm): | 1000 ×1100 ×1600 | |||

Weight(kg): | 1000(kg) |

Max machining size(mm) | φ95 ×80 mm | |||

Cutting speed (㎝²/㎜) | 3-6(㎝²/㎜) | |||

Degree of balance sheets by cutting deviation(mm) | ±0.005㎜ | |||

Cutting film thickness(mm) | ≥0.30 | |||

The thin-cut tolerance(mm) | ±0.005㎜ | |||

Horizontal stroke(mm) | 120㎜ | |||

Longitudinal travel(mm) | 110㎜ | |||

Spindle Electrical | 3 Phase 1.1kw | |||

Spindle Speed (r/min) | 2800Rev/min | |||

Adjust the amount of work clamp: Horizontal angle | ±45º | |||

Pitch angle of elevation | ±10º | |||

Vertically(mm) | 20 | |||

Cooling tank capacity(kg | 50kg | |||

Cooling tank motor | 3 Phase 0.12kw 2780r/min | |||

Power | Three-phase four-wire 50Hz 380V | |||

Dimensions(mm) | 1130 ×850 ×1 500 | |||

Weight(kg) | 1400(kg) |

Packing & Delivery

![]()

![]()

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Our Factory

![]()

![]()

![]()

Certifications

![]()

Quality Assurance

Quality Assurance

The equipment is guaranteed for one year and maintained for life.

Make first-class equipment with heart, and make first-class service with heart.

Company Profile

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com