GoodCut полуавтоматический Nanxing Кромкооблицовочный станок по хорошей

- Категория: Wood Based Panels Machinery >>>

- Поставщик: Jinan,GoodCut,CNC,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.22 $* | 0.34 $* |

| Aug-16-2025 | 0.42 $* | 0.16 $* |

| Jul-16-2025 | 0.38 $* | 0.63 $* |

| Jun-16-2025 | 0.62 $* | 0.76 $* |

| May-16-2025 | 0.27 $* | 0.19 $* |

| Apr-16-2025 | 0.32 $* | 0.49 $* |

| Mar-16-2025 | 0.8 $* | 0.4 $* |

| Feb-16-2025 | 0.86 $* | 0.91 $* |

| Jan-16-2025 | 0.80 $* | 0.26 $* |

Характеристики

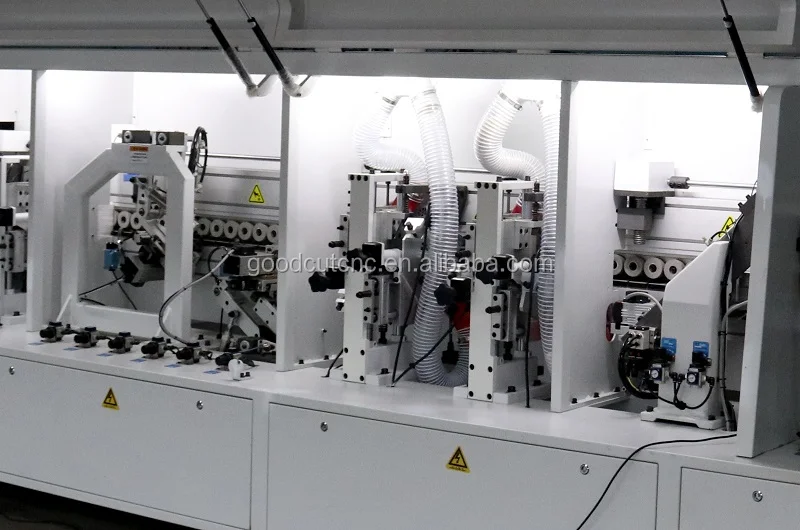

CE Certification Wood Furniture semi-auto edge banding machine for woodworking

All the machine can be customized according to your own requirements. For example the machine is designed with linear or carouse tool changer, the amount of head or spindle can be added, also the rotary device is allowed to be installed on the machine……All in all, all the specification of machine can be customized!!! Now just click the following machine for more details!

Feature emi-auto edge banding machine:

1.The emi-auto edge banding machine is a processing equipment for automatic edge banding of panel furniture, saving labor and time,

2. perfect edge banding, and advanced

3. The configuration and reasonable design reduce the difficulty of work, reduce the dependence on skilled workers, and greatly

4. improve the quality of the product.

5. The machine is widely used in cabinets, wardrobes, custom panel furniture and other industries.

Parameter emi-auto edge banding machine:

| Conveying drive | conveying motor(TDD) |

| Linear transmission | chain block, pressing wheel(Hessen) |

| Electrical equipment | Schneider |

| Controller PLC | Delta |

| Frequency inverter | LITEON,TAIWAN |

| Temperature control light sense | AUTONICS |

| Magnetic induction | AirTAC |

| High frequency | World motor |

| Travel switch | Honevwell |

| Cylinder | AirTAC |

| Solenoid valve | EASUN |

| Linear guide rail | Hiwin |

| Feed speed | 26-28-32m/min |

| Thickness edge banding | 0.3-2mm |

| Panel thickness | 9-60mm |

| Panel length | ≥150mm |

| Panel width | ≥50mm |

| Work air pressure | 0.7mpa |

1.Adopt domestic famous motor and high quality electrical components.

2.The fuselage is firm and steady,thus increasing the stability of the whole machine.

3.Aluminum alloy beam is a relatively advanced method, its precision and straightness are far superior to cast iron.

4.Auto cleaning, high precision, high efficiency.

5.The machine can be customized.

6.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

7.Multiple Air cylinder will assembled on the machine, mainly used for positioned location assured the panel materials processing accuracy in a very high level.

8.Secondary Dust Exhaust System, mainly used for sawdust collection during processing period, to keep the material smooth and clean.

9.The machine adopts the devices of sound insulation, controlling of dust, platform frame Micro adjustment by manual operation.

8.The buffing part is used to clean the finished panel and buff it with a cotton buffing wheel.

Advantage:

1.This edge bander is ideal for building an automatic production line. Stability and controlled ability are the most important factors for an equipment to be part of production line.

2.Pre-milling equipment with double trim-blades works on the waved effect that is caused by precise saw.

3.The glue mechanism adopts a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

4.End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

5.Rough &Fine Trimming unit, with two individual high frequency motors, trim the exceeding edge on the top and bottom side of the panel, ensure the top and bottom side of the edge smooth and even.

6.Scraping unit for a perfect finishing of the applied edge.

7.The buffing device adopt the board processed by cotton polishing wheel, by end-polishing to make a more smooth surface.

8.Grooving is a optional function for edge banding machine. It's used to slot out one groove on panel to install glass, back panel etc.

Samples&Application:

1.Edge banding machine in woodworking is used in banding edge of desks,carbinet,wardrobe and stright line furniture.The edge bander can be PVC,melamine,wood based works and so on,with powerful fuctions as edge feeding,sticking,material cutting,front-back trimming.

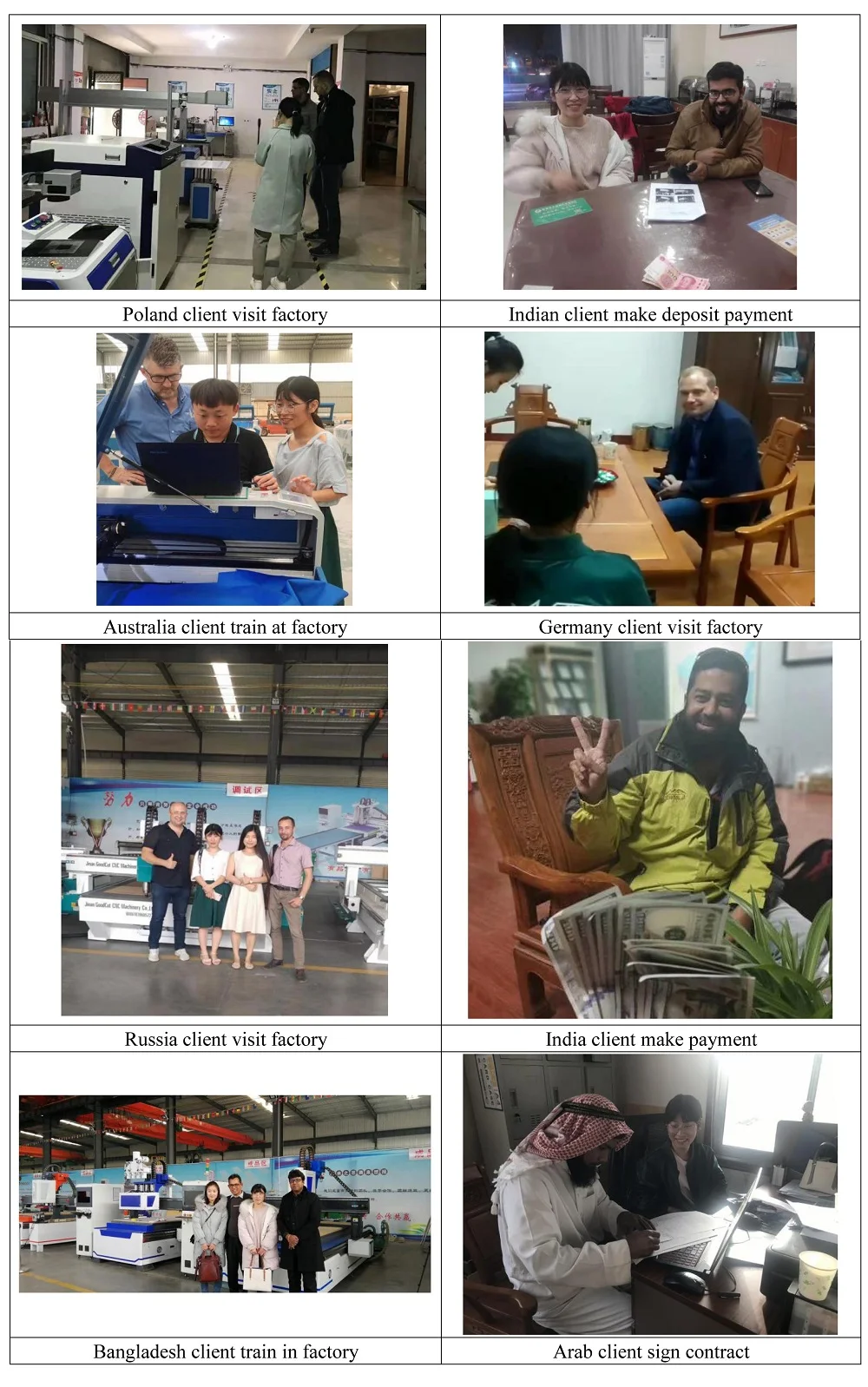

About US:

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

Good Quality

1. 15 engineers with more than 10 years rich working experience, manufacture high precision machines;

2.Three-day 72-hour testing machine inspection, after confirming that the machine has no quality problems, then it will be shipped;

3. 4 QC staffs do strict evaluations on in-coming inspections, in-process inspections and final inspections.

Good Price

1. GoodCut manufactures about 50 sets of machines per month, with a large sales volume. We have long-term cooperation with parts suppliers, can get advantageous prices of parts, so that the price of machine is very competitive;

2. GoodCut aims to develop long-term cooperation with new and regular customers, and to give customers the best prices with the most sincere attitude.

Good Service

1. English manual and video for machine using and maintaining, explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching.

Jinan GoodCut CNC Machinery Co.,Ltd

Website:www.goodcutcnc.com

www.goodcutcnc.com

Sasha Song

Mobile/WhatsApp/WeChat:008618396853738