Qt40-3a машина по производству Бетонных блоков цена цемента немецкая технология 1100*650 мм В переменного тока 50-200 45-60 Гц 7 блоков/пресс-форм

- Категория: >>>

- Поставщик: Longkou,deyi,machinery,group,co.,ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.78 $* | 0.76 $* |

| Aug-16-2025 | 0.52 $* | 0.38 $* |

| Jul-16-2025 | 0.86 $* | 0.23 $* |

| Jun-16-2025 | 0.33 $* | 0.53 $* |

| May-16-2025 | 0.37 $* | 0.22 $* |

| Apr-16-2025 | 0.65 $* | 0.21 $* |

| Mar-16-2025 | 0.9 $* | 0.80 $* |

| Feb-16-2025 | 0.30 $* | 0.42 $* |

| Jan-16-2025 | 0.45 $* | 0.70 $* |

Характеристики

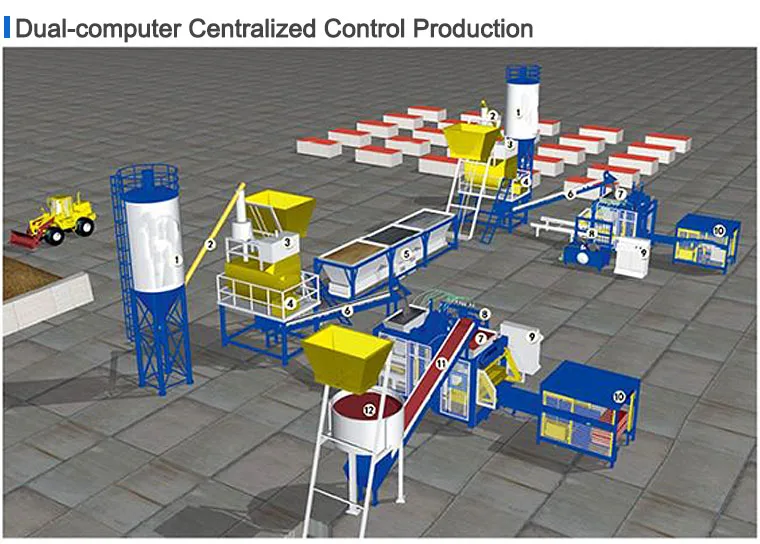

Hot Sale Full Auto Hydraulic Hollow Cement Brick Making Machine

Forming host: This equipment is a vibrating four-column forming brick machine. Due to its unique design and advanced forming principle, the machine realizes the frequency conversion automation of board feeding, brick output, aggregate, fabric, and vibration stacking. One machine has multiple functions, stable performance, easy operation and high output.

Vibration system: the use of four-axis vibration, the German one brick machine patent technology (vibrator and vibration platform integrated design) penetrating vibration, high vibration frequency, vibration force uniform, vibrator power is divided into frequency conversion vibration.The maximum use of effective vibration power, the balance of the vibration power to the parts of the mold box, the maximum degree of improvement of product density and mold service life.

Hydraulic system: independently designed by Deyi Brick Machine, the tubing design is arranged neatly, and the tubing direction is more reasonable.The main oil pump, double proportional valve and solenoid valve are all made of domestic high-end manufacturers' parts and assembled by the core technology of Dei brick machine, with stable performance, very low failure rate, fast and stable walking speed of each action.Oil pipe imported from Italy, aging resistance, no oil leakage, long life.The joint wire adopts domestic high-end manufacturers' products to avoid oil leakage and seepage, and ensure the stability of pressure and good operation of equipment.

Electronic control system: PLC automatic (three frequency conversion) comprehensive control technology, independent frequency conversion design for each part of the whole line.PLC adopts Taiwan Fengwei, touch screen, sensor, frequency converter, circuit accessories are Omron, Taiwan Shilin, Jietong, sinusoid, ABB and other famous brand accessories.

Distributing system: the new semi-closed storage hopper, the storage hopper adopts an electronically controlled opening, the discharge amount can be adjusted at will according to the material consumption of different bricks, and the feeding is more accurate. The distributing cart adopts a reciprocating gear type, which is fast and uniform. Add materials to the mold. The bottom plate of the placing trolley adopts Shanghai Baosteel NM400 high-strength wear-resistant plate, which greatly improves the service life. The stirring gear adopts 35cro quenching, which has good willfulness, good wear resistance, and bolt-type design, which is more convenient to replace.

Brick connecting machine: The operation is frequency conversion control, the speed is adjustable, the operation is stable, and the finished product is not damaged.

The lifting platform of the distributing truck: adopts hydraulic top lifting, beautiful, practical, convenient and quick to change the mold

Safety net: using hanging safety net, maintenance and disassembly are more convenient, convenient to use and safer

|

Maximum forming area | 1,100×650mm | Main vibration form | Tai Zhen |

Host size | 5600×2600×2800 | Vibration frequency | 45-60HZ |

Finished product height | 50-200mm | Electric control system | VlGOR |

Molding cycle | 12-18 seconds (depending on the shape of the product) | Total power | 44.8kw |

Exciting force | 80KN | gross weight | 9T |

Pallet size | 1,150×750×(12-35)mm | ||

Number of forming blocks | 390×190×190mm(7 blocks/mold) | ||