100% безопасная силиконовая резиновая форма RTV 2 части жидкий силиконовый каучук для изготовления

- Категория: Silicone Rubber >>>

- Поставщик: Sanpin,New,Materials,(Dongguan),Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.93 $* | 0.22 $* |

| Aug-17-2025 | 0.89 $* | 0.25 $* |

| Jul-17-2025 | 0.65 $* | 0.10 $* |

| Jun-17-2025 | 0.0 $* | 0.38 $* |

| May-17-2025 | 0.76 $* | 0.11 $* |

| Apr-17-2025 | 0.83 $* | 0.69 $* |

| Mar-17-2025 | 0.40 $* | 0.24 $* |

| Feb-17-2025 | 0.64 $* | 0.50 $* |

| Jan-17-2025 | 0.65 $* | 0.93 $* |

Характеристики

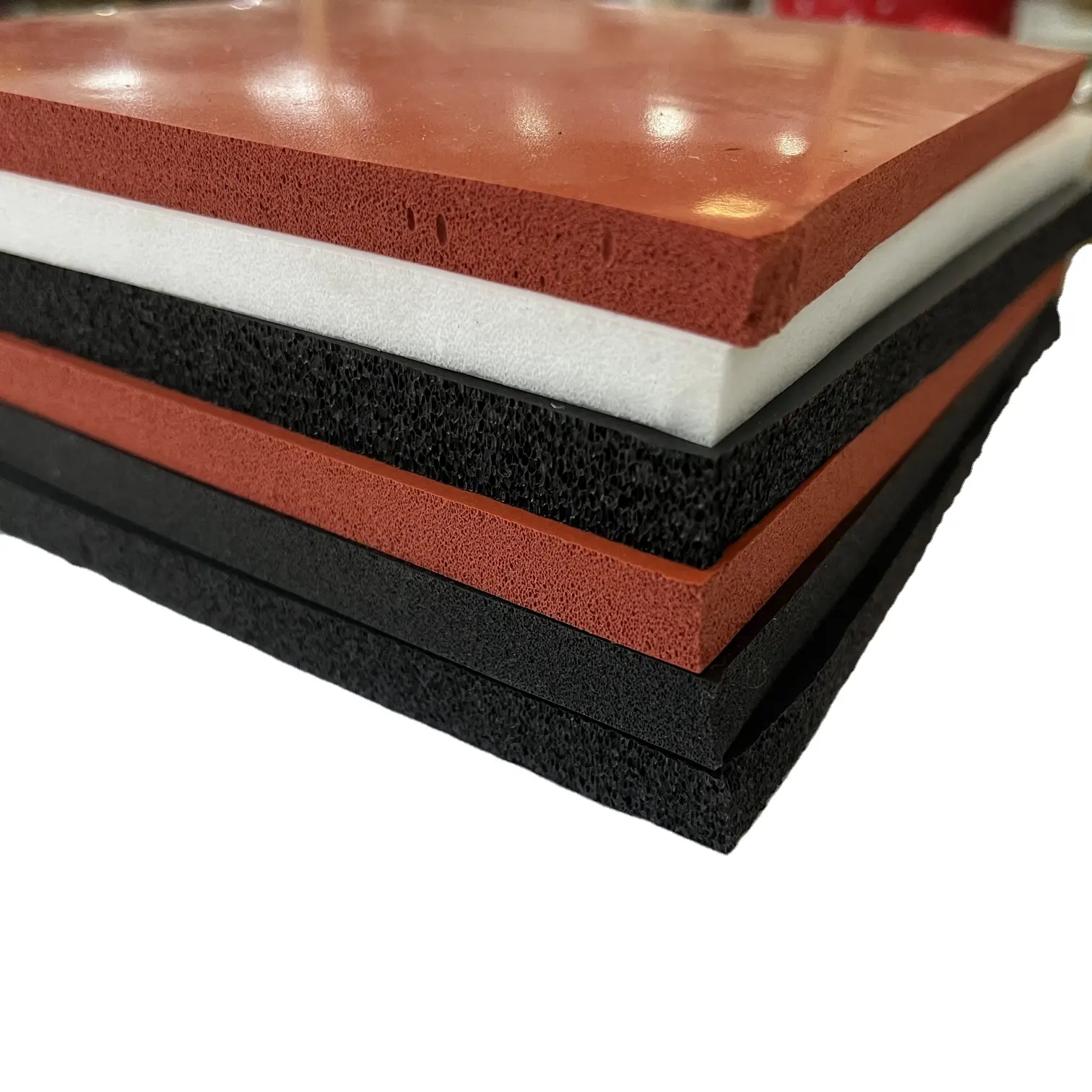

Tin cure liquid silicone is also called condensation cure liquid silicone, molding silicone. rtv 2 silicone. It is the materials of liquid shape. can be used in making rubber molds to copy any solid subjects. Here are some properties of the rtv silicone.

1. Easy to use by mixing the rtv silicone part A and part B only

2. Good flexibility.

3. Can copy the very fine detail of the surface

4. Strong tear strength and tensil strength

5. long shelf time like 12 months and more

6. adjustable working time and curing time.

7. Good liquidity and good flow ability.

How to use the rtv 2 silicone:

1. clean the surface of the prototype.

2. spray some release agent on the surface of the prototype.

3. put it into a frame with bottom ( like a container) and fix it.

4. mix the liquid silicone part A and Part B with certain mixing ratio completely, usually 100:3.

5. if you have vacuum chamber, put the mixed liquid silicone into the chamber and degas for 2 minutes.

6. pour the rtv silicone on the subject in the container fully.

7. after 24 hours. remove the rubber molds from the prototype.

8. rubber mold is done. start using the rubber mold.

How to make a silicone rubber mold?

1. Filling mold(Full mold,Two halves of the mold)

(1)Full mold:

A.Prepare a frame,put the copied prototype into it and fix it.

B.Weigh a certain amount of mold glue and hardener in proportion to mix and stir.

C.Demould use after curing.

(2)Two halves of the mold:

A.First fix and wrap half of the prototype with clay, repair the surface of the clay, and then fix it with a frame.

B.Weigh a certain amount of mold glue and hardener in proportion to mix and stir.

C.Pour rubber into the frame.

D.After the potting material is half dry, remove the fixed clay and brush the release agent on the surface of the rubber material to prevent adhesion.

E.Consistent with the first step.

F.Demould use after curing.

2. Two-piece brush mold

A.First fix and wrap half of the prototype with clay, repair the surface of the clay, and then fix it with a frame.

B. Brush the release agent on the surface of the rubber material to prevent adhesion.

C.Weigh a certain amount of mold glue and hardener in proportion to mix and stir.

D.Pour the rubber material on the prototype, and then evenly brush the rubber material on the prototype.

E.After the glue is dry, brush the second layer and the third layer, and the steps are the same as the first layer.

F.After the rubber is completely dry, apply a thick layer of plaster.

G.After removing the clay, the other side is made in the same step as above.

H.Demould use after curing.

1. what is the product can you offer?

we can supply silicone as below:

tin cure liquid silicone rubber, tin cure silicone. rtv 2 silicone. 100:3 silicone.

platinum cure liquid silicone rubber, platinum cure silicone. 1:1 silicone. food grade silicone.

food grade liquid silicone rubber.

2. why should I choose your company?

we are the biggest manufacturer of tin cure liquid silicone here in China, we have been in this business for more than 18 years experience. ISO 9001 certificate.

for the product, Rohs and reach certificate.

3. can you supply free sample?

yes, we can offer 1kg sample for free.

4. how can you help me on the shipping?

if you can not find the shipping agent, we can help you to find here in China. with best prices and good service.