Прямая поставка с завода 3D тиснение древесина WPC настил патио противоскользящее напольное покрытие уличный Деревянный

- Категория: Flooring & Accessories >>>

- Поставщик: Anji,Zhengyuan,WPC,Decoration,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 2.24 $* | 2.64 $* |

| Aug-17-2025 | 2.37 $* | 2.21 $* |

| Jul-17-2025 | 2.2 $* | 2.17 $* |

| Jun-17-2025 | 2.41 $* | 2.14 $* |

| May-17-2025 | 2.75 $* | 2.98 $* |

| Apr-17-2025 | 2.39 $* | 2.97 $* |

| Mar-17-2025 | 2.39 $* | 2.93 $* |

| Feb-17-2025 | 2.45 $* | 2.76 $* |

| Jan-17-2025 | 2.54 $* | 2.64 $* |

Характеристики

Product Description

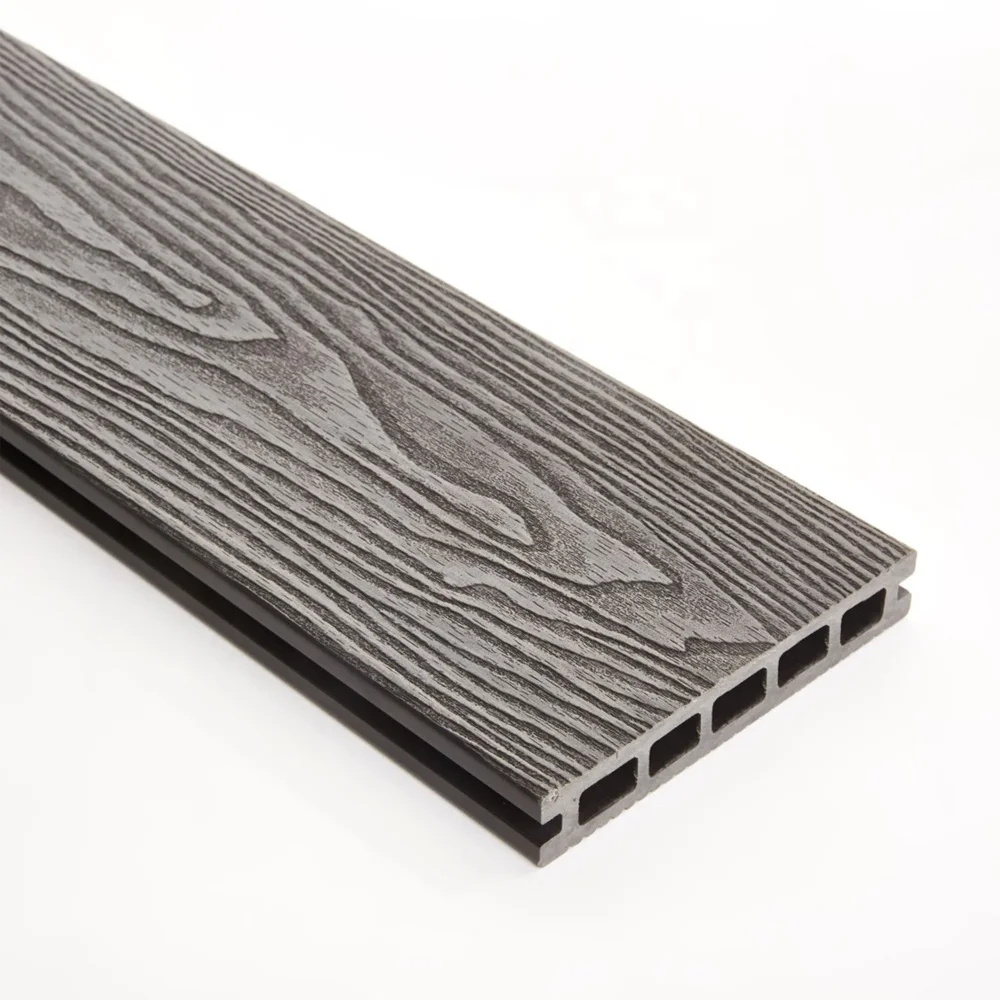

3D Embossed Wood Grin WPC Decking Patio Wooden Flooring Outdoor Composite Decking

Product Detail

-------Quick Detail-------

Width:146m Thickness: 25mm

Length: 2.2m, 2.8m, 3.6m, 4m or customized

Ingredient: 60% Wood Powder + 30%

Plastic(HDPE) + 10% Additive

Color:Black, Grey, Brown, Oak, Teak, white, etc

Certificates: CE, ISO14001,ISO9001, SGS, FSC

Place of original: Anji, China

-------Product Structure-------

-------Wood Grain Choice-------

-------More Size Choice-------

140 x 25 mm, Solid

146 x 23 mm, Square Hollow

150 x 23 mm, Circle Hollow

Advantages

Accessory

Easy to Install

Save time/effort/labour cost

Cerfificates

Company Introduction

We are a manufacturer which produces a new type of wood-plastic composite decoration material, and specializes in design,production and sales.

This kind of decoration material is a new, green, environmental-friendly and ecological product which is specially treated and made from RECECLED PLASTIC, HDPE and WOOD FIBRE. The decoration material is not only provided with the nature of wood feature, but also can be supplied for the varieties of color options to meet the customers’ requirements. Meanwhile, our product also possesses some other superior characteristics like keeping its shape, rot prevention, no cracking, fireproof, pest-resistance, easy to install and no need to maintain and so on.

This kind of decoration material is a new, green, environmental-friendly and ecological product which is specially treated and made from RECECLED PLASTIC, HDPE and WOOD FIBRE. The decoration material is not only provided with the nature of wood feature, but also can be supplied for the varieties of color options to meet the customers’ requirements. Meanwhile, our product also possesses some other superior characteristics like keeping its shape, rot prevention, no cracking, fireproof, pest-resistance, easy to install and no need to maintain and so on.

Project

FAQ

1. What's WPC?

WPC is short for Wood Plastic Composite. The combination of the raw materials are mostly 30% recycled plastic (HDPE) and 60% wood

powder, plus 10% additives such as anti-UV agent, lubricant, light stabilizer and etc.

2. What's the process to make WPC panels?

(a) Mix raw materials according to certain formula, then make them into pellets.

(b)By extrusion machine and mold, shape the products in customized profile and size.

(c)Do surface treatment such as sanding or embossing, then cut the WPC panels by requested length before package.

3. What's the benefits to use composite wood panels?

(a) Composite panel is waterproof, fire retardant, UV resistant, anti-slip, maintenance free and durable.

(b) Its profiles, lengths, colors, surface treatments are adjustable.

(c) It's easy to install and cost efficient.

(d) Since the raw materials are recycled, the product itself is eco-friendly.

4. Why us?

(a) We have been in the indusrty for more than 10 years, we have experience in R&D, sales& field installation. For any question

regarding any aspect of the product we can provide you professional advice and solution.

(b) Based on our marketing research, we are confident to provide you competitive prices based on reliable quality.

(c) We take strict control on product quality and we assure our clients punctual lead time. We are proud of our sales network

having expanded to more than 30 countries all over the world, and it keeps growing.

5.- Can I order samples?

Yes, of course; we can provide free samples for your check.

6.- The lead time and the payment term?

Usually the lead time is 20-30 days after receiving the deposit.

Our regular payment term is TT, 30% as the deposite, 70% should be paid before the delivery.

Other payment terms can be negotiated with us!

WPC is short for Wood Plastic Composite. The combination of the raw materials are mostly 30% recycled plastic (HDPE) and 60% wood

powder, plus 10% additives such as anti-UV agent, lubricant, light stabilizer and etc.

2. What's the process to make WPC panels?

(a) Mix raw materials according to certain formula, then make them into pellets.

(b)By extrusion machine and mold, shape the products in customized profile and size.

(c)Do surface treatment such as sanding or embossing, then cut the WPC panels by requested length before package.

3. What's the benefits to use composite wood panels?

(a) Composite panel is waterproof, fire retardant, UV resistant, anti-slip, maintenance free and durable.

(b) Its profiles, lengths, colors, surface treatments are adjustable.

(c) It's easy to install and cost efficient.

(d) Since the raw materials are recycled, the product itself is eco-friendly.

4. Why us?

(a) We have been in the indusrty for more than 10 years, we have experience in R&D, sales& field installation. For any question

regarding any aspect of the product we can provide you professional advice and solution.

(b) Based on our marketing research, we are confident to provide you competitive prices based on reliable quality.

(c) We take strict control on product quality and we assure our clients punctual lead time. We are proud of our sales network

having expanded to more than 30 countries all over the world, and it keeps growing.

5.- Can I order samples?

Yes, of course; we can provide free samples for your check.

6.- The lead time and the payment term?

Usually the lead time is 20-30 days after receiving the deposit.

Our regular payment term is TT, 30% as the deposite, 70% should be paid before the delivery.

Other payment terms can be negotiated with us!

Contact

Jessie

Export Department Sales Manager

MP/WhatsApp/Wechat: +86-132 9182 5779

Anji Zhengyuan WPC Decoration Material Co., Ltd

Add: Building 1-2 and 4-8, The Center of Bamboo of

Technology and Industry Park, Xiaofeng Town,

Anji County,Zhejiang Province,China

www.zjwpc.com

Export Department Sales Manager

MP/WhatsApp/Wechat: +86-132 9182 5779

Anji Zhengyuan WPC Decoration Material Co., Ltd

Add: Building 1-2 and 4-8, The Center of Bamboo of

Technology and Industry Park, Xiaofeng Town,

Anji County,Zhejiang Province,China

www.zjwpc.com