Конвейерная лента для суши Faith Factory

US $170.00

Поделиться:

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 5772.50 $* | 6061.56 $* |

| Aug-18-2025 | 5723.85 $* | 6009.75 $* |

| Jul-18-2025 | 4802.8 $* | 5042.11 $* |

| Jun-18-2025 | 5626.79 $* | 5907.41 $* |

| May-18-2025 | 4899.66 $* | 5144.97 $* |

| Apr-18-2025 | 5529.75 $* | 5805.89 $* |

| Mar-18-2025 | 5481.61 $* | 5755.8 $* |

| Feb-18-2025 | 5432.44 $* | 5704.65 $* |

| Jan-18-2025 | 5384.12 $* | 5653.74 $* |

Technology Parameter | ||||||||||

Model | CFL160 | CFL170 | CFL190 | CFL220 | ||||||

Output(kg/h) | 500 - 900 | 700-1200 | 1200-1500 | 1300-1700 | ||||||

Length(mm) | 24000 | 26000 | 28000 | 29000 | ||||||

Width(mm) | 1500 | 1500 | 1500 | 1500 | ||||||

Height(mm) | 3000 | 3000 | 3300 | 3500 | ||||||

1. For PC, PA: Screw Feeder For PET: U-shaped Screw Feeder | Power(KW) | 5.5 | 5.5 | 5.5 | 5.5 | |||||

Diameter(mm) * Screw Feeder *U-shaped | φ133 φ200 | φ200 | ||||||||

2. Water Tank | Size(mm) | 300 x 500 x 4000 | 300 x 500 x 5000 | 300 x 500 x 5000 | 300 x 500 x 6000 | |||||

3. Bracket Supporting Rack With Blower | Power(KW) | 1.5 | 2.2 | 1.5 x Two Blowers | 1.5 x Two Blowers | |||||

4. Plastic Cutting Machine | Size(mm) | φ200 x 200 | φ200 x 300 | φ200 x 300 | φ200 x 300 | |||||

Power(KW) | 15 | 15 | 22 | 22 | ||||||

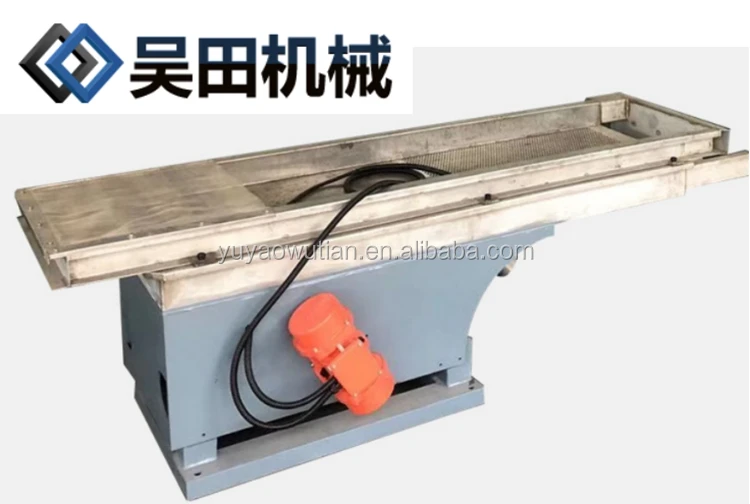

5. Vibration Sieve | Vibrator Power(KW) | 0.08 | 0.08 | 0.15 | 0.25 | |||||

6. Particle Blower Feeder | Power(KW) | 4 | 4 | 5.5 | 5.5 | |||||

Capacity(kg) | 500 | 500 | 500 | 500 | ||||||

7. Single Screw Granulator with Feeder & Screen Changer (Stainless Steel Mesh Head) | Diameter of Screw (mm) | φ100 | φ120 | φ140 | φ220 | |||||

7. Granulator with Feeder & Screen Changer (Chemical Fiber Mesh Head) | Power of Granulator (KW) | 220 | 250 | 315 | 375 | |||||

Power of Feeder (KW) | 1.5 | 2.2 | 2.2 | 2.2 | ||||||

8. PLC | OPTIONAL | |||||||||

9. Filter Cleaner | Vacuum Heating Furnace | |||||||||

Power of High Pressure Cleaning Pumps (KW) | 3 | 3 | 3 | 3 | ||||||

Technology Parameter | ||||||||||||||

Model | CFL100 | CFL110 | CFL120 | CFL130 | CFL140 | CFL150 | ||||||||

Output(kg/h) | 150-220 | 180-290 | 200-350 | 300 - 400 | 400-450 | 450 - 600 | ||||||||

Length(mm) | 18500 | 19000 | 19000 | 21000 | 22000 | 22500 | ||||||||

Width(mm) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | ||||||||

Height(mm) | 2000 | 2000 | 2200 | 2300 | 2500 | 2500 | ||||||||

1. For PC, PA: Screw Feeder For PET: U-shaped Screw Feeder | Power(KW) | 2.2 | 2.2 | 2.2 | 5.5 | |||||||||

Diameter(mm) * Screw Feeder *U-shaped | φ133 φ200 | φ200 | ||||||||||||

2. Water Tank | Size(mm) | 300 x 500 x 2500 | 300 x 500 x 2500 | 300 x 500 x 2500 | 300 x 500 x 4000 | 300 x 500 x 4000 | 300 x 500 x 4000 | |||||||

3. Bracket Supporting Rack With Blower | Power(KW) | 1.1 | 1.1 | 2.2 | 1.5 x 2 Two Blowers | 1.5 | ||||||||

4. Plastic Cutting Machine | Size(mm) | φ200 x 200 | φ200 x 200 | φ200 x 300 | φ200 x 300 | φ200 x 300 | ||||||||

Power(KW) | 4 | 4 | 5.5 | 5.5 | 7.5 | 7.5 | ||||||||

5. Vibration Sieve | Vibrator Power(KW) | 0.08 | 0.08 | 0.08 | 0.15 | 0.25 | ||||||||

6. Particle Blower Feeder | Power(KW) | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | |||||||

Capacity(kg) | 500 | 500 | 500 | |||||||||||

7. Single Screw Granulator with Feeder & Screen Changer (Stainless Steel Mesh Head) | Diameter of Screw (mm) | φ100 | φ110 | φ120 | φ130 | φ140 | φ150 | |||||||

7. Granulator with Feeder & Screen Changer (Chemical Fiber Mesh Head) | Power of Granulator (KW) | 55 | 75 | 90 | 90 | 110 | 132 | |||||||

Power of Feeder (KW) | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | |||||||||

8. PLC | OPTIONAL | |||||||||||||

9. Filter Cleaner | Vacuum Heating Furnace | |||||||||||||

Power of High Pressure Cleaning Pumps (KW) | 3 | 3 | 3 | |||||||||||

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com