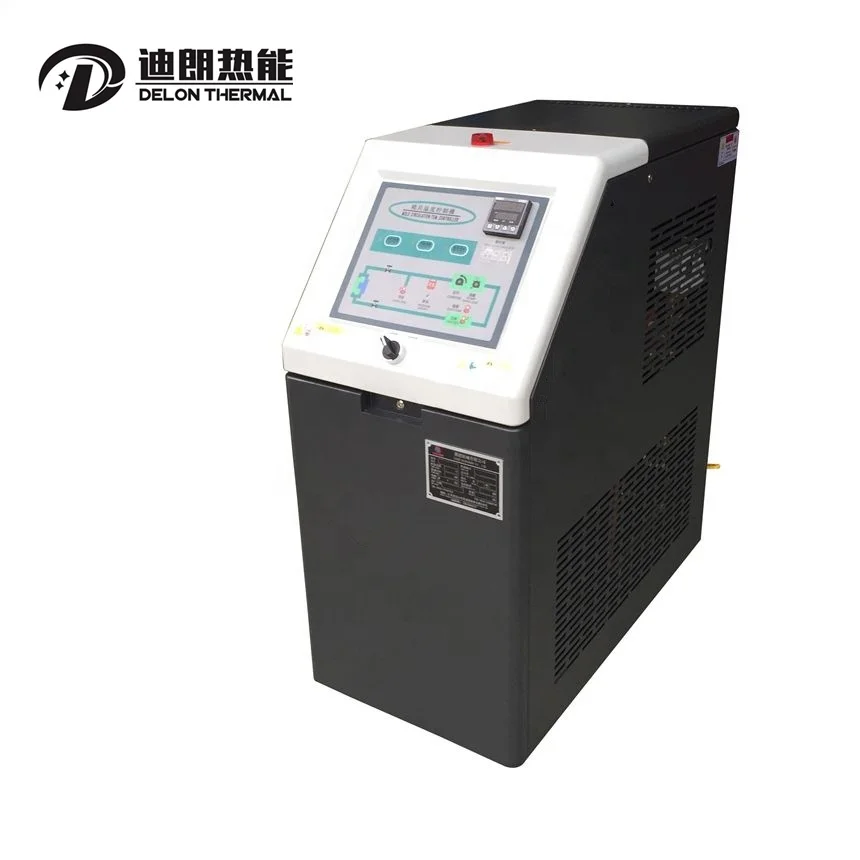

Электрический термический жидкостный нагреватель с ПИД-управлением для

- Категория: Пластиковое вспомогательное оборудование >>>

- Поставщик: Zhangjiagang,Delon,Thermal,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 3689.73 $* | 3873.72 $* |

| Aug-19-2025 | 3658.57 $* | 3841.9 $* |

| Jul-19-2025 | 3069.32 $* | 3222.31 $* |

| Jun-19-2025 | 3596.2 $* | 3776.56 $* |

| May-19-2025 | 3131.30 $* | 3288.13 $* |

| Apr-19-2025 | 3534.85 $* | 3711.25 $* |

| Mar-19-2025 | 3503.65 $* | 3678.93 $* |

| Feb-19-2025 | 3472.24 $* | 3646.80 $* |

| Jan-19-2025 | 3441.45 $* | 3613.4 $* |

Характеристики

Introduction for Thermic Fluid Heater:

The working principle of small electric thermic fluid heater (as known as mould temperature controller) uses heating wire to heat the heat-conducting oil, and then through the high-temperature circulation pump to transfer the heated heat-conducting oil to the temperature control equipment to play a role in heat transfer, through the temperature-sensing line to detect the temperature of the oil temperature machine outlet, the temperature controller according to the temperature collected to adjust the temperature accuracy. When the oil temperature is high, the heating wire stops heating, and at the same time opens the cooling solenoid valve to discharge the external low temperature cooling water into the heat exchanger on the pipeline for indirect heat exchange so as to regulate the temperature.

One. Operation mode:

Imported PC microcomputer light touch control, with a beautiful and generous appearance

ONE-TOUCH automatic exhaust function after startup, automatically heat up the mold after eliminating the air.

Two. Mechanical Piping System:

1. All internal pipelines are seamless stainless steel pipes, uniform heating, small pipe loss.

2. Equipped with pressure relief circuit device, oil shortage alarm, to protect the pump oil pump and heat pipe.

3. Fast and stable heating and cooling speed, it takes only about 10 minutes from empty to 200 ℃.

4. Circulation system oil pump adopts "YUAN SHIN" high pressure and high flow pump of 320℃, good heat conduction effect, fast temperature rise of mold, small temperature difference, energy saving more than 20%.

5. The use of flange type Swedish wire double power stainless steel electric heating elements, suitable for different temperature control occasions, imported electric heating wire, long service life, not easy to burn.

6. Solenoid valve using Taiwan original imported brand UNID, high temperature resistance 180 ℃.

7. Return oil temperature gauge, can monitor whether there is obstruction in the mold hole, injection molding conditions are stable.

8. Cooler: Adopt imported plate heat-exchanger, fast cooling speed, accurate temperature control.

Technical Specifications for Thermic Fluid Heater:

Model / Series | Unit | DEL-06(A) | DEL-09(A) | DEL-12(A) | DEL-18(A) | DEL-18(B) | DEL-24(B) |

Max. outlet oil temperature | °C | 200 (Adjustable) | |||||

Main power supply | V/HZ | 380V±5%/50HZ, 3Ph (3P+N+E) or Custom made | |||||

Heat transfer medium | — | Heat transfer oil | |||||

Cooling mode | — | Indirect cooling | |||||

Input power | kW | 6 | 9 | 12 | 18 | 18 (9+9) | 24 (12+12) |

Oil pump power | HP | 0.5 | 1 | 2 | 3 | 3 | 5 |

Max. flow rate of pump | m3/h | 1.8 | 4.2 | 5.4 | 7.2 | 7.2 | 9 |

Max. system pressure | bar | 2 | 2 | 2.5 | 2.5 | 3 | 3 |

Oil Inlet diameter | DN | 15 | 15 | 15 | 20 | 20 | 20 |

Oil outlet diameter | DN | 15 | 15 | 15 | 20 | 20 | 20 |

Expansion tank volume | Liter | 7 | 10 | 25 | 35 | 35 | 40 |

System power consumption | kW | 7 | 10 | 12 | 20.5 | 20.5 | 27.75 |

Cooling oil pipe | INCH | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 | 1/2 |

Circulation oil pipe | INCH | 2/8×4 | 3/8×4 | 3/8×4 | 1/2×4 | (3/8×4) ×2 | (3/8×4) ×2 |

Overall size | L mm | 630 | 630 | 850 | 850 | 1000 | 1000 |

W mm | 330 | 330 | 400 | 400 | 430 | 430 | |

H mm | 730 | 730 | 820 | 820 | 1100 | 1100 | |

Net weight | Kg | 75 | 75 | 90 | 100 | 160 | 160 |

Note:

1. The choice of oil pump is as per customers’ requirements.

2. The diameter of inlet & outlet could be modified as per customers’ requirements.

3. The above specifications are subject to change without notice, special requirements could be designed.