Низкая цена небольшой ручной коврик принтер солнцезащитные очки чернильная подставка печатная машина для

- Категория: Pad Printers >>>

- Поставщик: Shenzhen,Eco,Printing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 940.22 $* | 987.5 $* |

| Aug-16-2025 | 932.56 $* | 979.64 $* |

| Jul-16-2025 | 782.72 $* | 821.73 $* |

| Jun-16-2025 | 916.61 $* | 962.98 $* |

| May-16-2025 | 798.64 $* | 838.34 $* |

| Apr-16-2025 | 901.99 $* | 946.17 $* |

| Mar-16-2025 | 893.69 $* | 938.59 $* |

| Feb-16-2025 | 885.13 $* | 929.21 $* |

| Jan-16-2025 | 877.97 $* | 921.18 $* |

Характеристики

Product Description

Description:

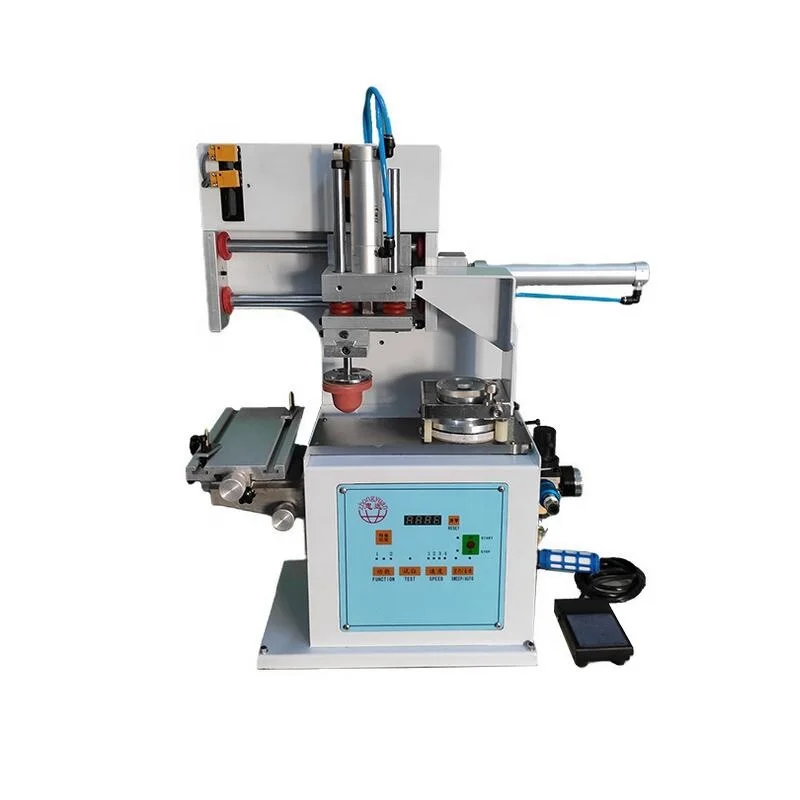

Small manual pad printer sunglasses ink cup pad printer printing machine for Ball Pen

1 colour pad printing machine for pens

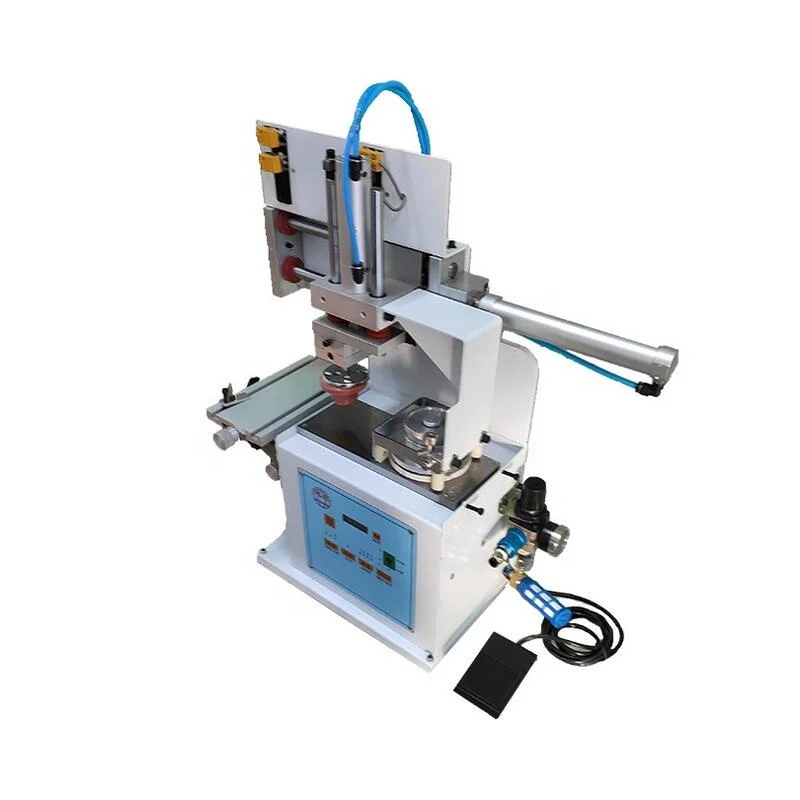

Desktop Pad Printer YK-TP1-100T is well suitable to pad printing on pens, toys, cups, cosmetic container, gift crafts, ball, mobile phone keypad, computer keyboard, household appliances etc.

It is with closed ink cup, can save 60% ink and 90% thinner comparing with open ink plate. use Printing plate Rang : long life thin(0.25-0.5 mm) steel plate ,Red polymer ,Thickness 10 mm steel plate.

pen printing machines for sale

YK-TP1-100T Desktop pad printer with close ink cup has exterior beautiful, small, easy operating, high quality, environment friendly /acceptable, competitive price, useful for small products, same as toys, pen, stationery, gift, ...

printing machine for plastic pen

Free Fitting:

1. One pcs steel plate

2. Two pcs silicone rubber pad

3. A suit tool

4. English manual operate .

Application area -----toys, pens, keyboard, plastic products, label, hardward. Controlled by microprocessor for easy

1. One pcs steel plate

2. Two pcs silicone rubber pad

3. A suit tool

4. English manual operate .

Application area -----toys, pens, keyboard, plastic products, label, hardward. Controlled by microprocessor for easy

operation.

1. Five-digit auto counter built-in;

2. Sealed cup is used for ink covering and store, Keep ink viscidity stabilization and environment clean;

3. Independent pads up/down stroke and speed adjustment;

4. Printing speed adjustable to fulfill various printing requirements;

5. "Inking twice, printing once"for thick ink film;

6. Able to sweep forward/backward without lowering pad to avoid ink drying at intervals

1. Five-digit auto counter built-in;

2. Sealed cup is used for ink covering and store, Keep ink viscidity stabilization and environment clean;

3. Independent pads up/down stroke and speed adjustment;

4. Printing speed adjustable to fulfill various printing requirements;

5. "Inking twice, printing once"for thick ink film;

6. Able to sweep forward/backward without lowering pad to avoid ink drying at intervals

Specification

Model NO | YK=TP1-100T |

Operation | Pneumatic |

Printing Colors | 1 |

Plate area | 100*250 mm |

Printing area | 80*80 mm |

Max printing speed | 2000PCS/H |

Closed ink cup size | 90 mm diameter size |

Wattage | 220V/ 50HZ |

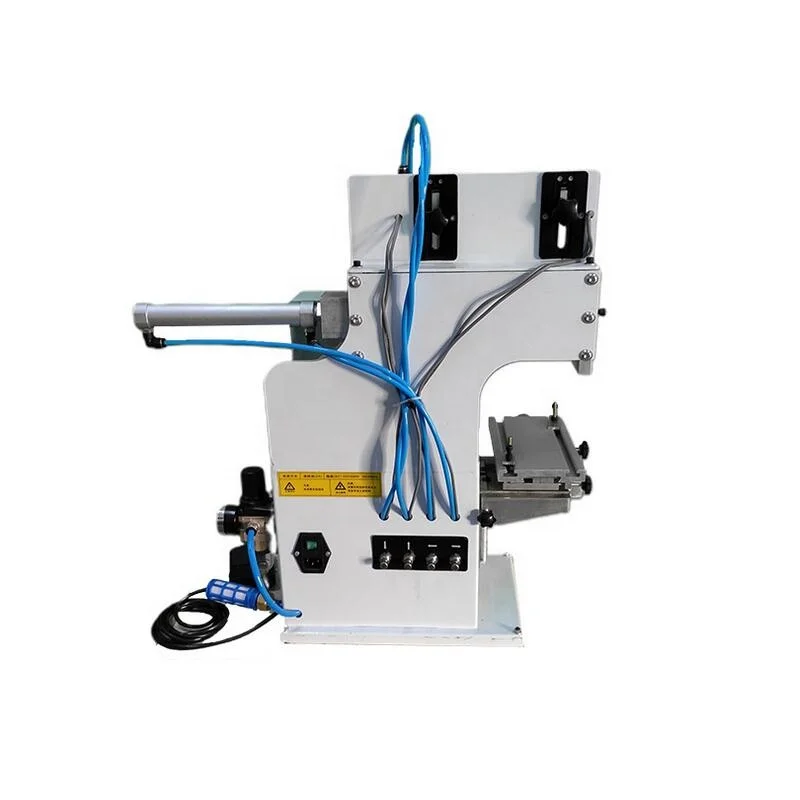

Air pressure | 0.4-0.6Mpa |

Gross weight | 35 KG |

Machine package size | 600 x 640 x 270 mm |

Warranty | For all our machines, we provide one-year warranty. Life-long on-line technical support and provide free parts when problems occur within one year not including shipping cost. Any warranty shipping cost to us is responsible by buyer. Any shipping cost to buyer is responsible by us. |

Packing & Delivery

desktop pneumatic closed ink cup pad printing machine print on face mask

1.Selling Units:Single item

2.Total package size: 600 x 640 x 270 mm3.Gross weight: 35kg

4.Package Type:plywood case /wooden case ,as required

Company Profile

Shenzhen Eco Printing Co.,LTD is mainly focusing on design, development, production and distribution of pad printers, screen printers machine ,UV curing unit ,IR oven machines and press-post equipment etc for 20 years.

Shenzhen Eco Printing Co., LTD was specializing in manufacturing ECO brands . including :various pad printer, silk screen printer, UV Curing machine ,IR dryer machine for 20 years.

We passed ISO-9001-2000 certification in 2001, and we are a member of SGIA and all of our industrial printers had passed CE standard.

we are the gold membership of Alibaba and Made-in-china and got a huge credit all the world .

There are customers from 98 countries to visit our factory and we had a good cooperation.

Mainly production:Automatically pad printing machines , pad printers Automatically Screen printing machines; screen printers,UV curing machine, pre-press equipment and Post-press equipment .

Shenzhen Eco Printing Co., LTD was specializing in manufacturing ECO brands . including :various pad printer, silk screen printer, UV Curing machine ,IR dryer machine for 20 years.

We passed ISO-9001-2000 certification in 2001, and we are a member of SGIA and all of our industrial printers had passed CE standard.

we are the gold membership of Alibaba and Made-in-china and got a huge credit all the world .

There are customers from 98 countries to visit our factory and we had a good cooperation.

Mainly production:Automatically pad printing machines , pad printers Automatically Screen printing machines; screen printers,UV curing machine, pre-press equipment and Post-press equipment .

Our service:

1.All of machines provide an English operation instruction.

2.All of machines can guarantee 1 year for free and provide specific video .

3.Welcome to visit our factory and we supply technology training any time.

1.All of machines provide an English operation instruction.

2.All of machines can guarantee 1 year for free and provide specific video .

3.Welcome to visit our factory and we supply technology training any time.

FAQ

Let us talk Industrial Pad Printing in the 21st Century

This article examines the latest advances in pad-printing technology and highlights several applications and innovations that will keep pad printing a fixture in the future of industrial printing.

Pad Printing has come a long way since its birth during the pre-industrial revolution. Gone are the painstakingly hand-etched plates, the mortar- and-pestle-ground ink pigments, and the gelatin pads used by the clockmakers of yesteryear to laboriously print elaborate dial faces.

Pad Printing has come a long way since its birth during the pre-industrial revolution. Gone are the painstakingly hand-etched plates, the mortar- and-pestle-ground ink pigments, and the gelatin pads used by the clockmakers of yesteryear to laboriously print elaborate dial faces.

Today’s pneumatically powered pad printers can handle 3000 or more impressions per hour on precision-conveyed parts that are automatically inspected to exacting tolerances with computerized vision systems and then unloaded by high-speed, robotic pick-and-place arms.

Keeping pace with global economic demands, industrial manufacturers have seen pad-printing technology evolve to integrate efficiency, ergonomics, and environmental improvements. Pneumatic and servo motor-driven electric machines have replaced hand-operated pad presses; high-speed gantry systems now take the place of manual loading and unloading; and hermetically sealed magnetic ink cups are used instead of wasteful open inkwells.

From medical-product manufacturers’ clean rooms to automotive-manufacturing assembly lines, pad-printing machines are adaptable enough to customize for an entire spectrum of industrial product marking and consumer product-decorating needs. This discussion of innovations in pad-printing technology presents case studies that illustrate the efficacy of modern pad presses and examines some challenging jobs for which pad printing was the ultimate solution.

Похожие товары

Sterile arterial blood gas syringe printing machine disposable

US $25500-$26000

Disposable Syringe Barrel Rotary Printing Machine

US $28000-$32000